Plate heat exchanger

A plate heat exchanger and heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed plate conduit components, etc., can solve the problems of small heat transfer temperature difference, affecting the heat exchange effect of heat exchangers, etc. Guaranteed temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

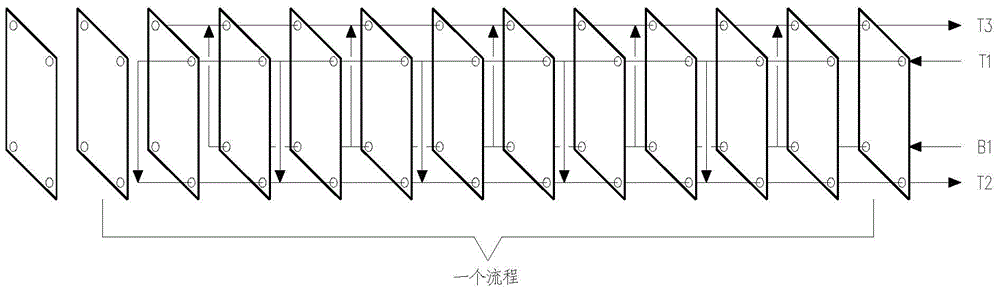

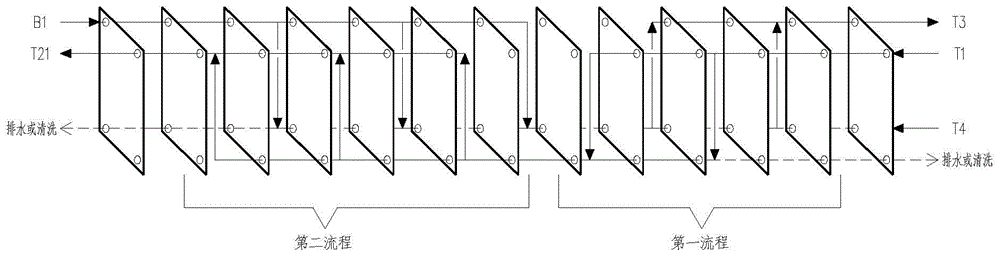

[0021] see figure 2 , the present invention provides a plate heat exchanger, including several plates, the plates are divided into two sets of plate groups from right to left, respectively the first plate group (corresponding to figure 2 In the first process) and the second plate group (corresponding figure 2 In the second process), the heat exchanger is provided with a circulating water return port T4, a heating water inlet T1, a water outlet T21 after heat exchange, a cold water inlet B1 and a hot water outlet T3, and the cold water inlet B1 and After heat exchange, the water outlet T21 is located on the left side of the heat exchanger, and the heating water inlet T1, the circulating water return port T4 and the hot water outlet T3 are all located on the right side of the heat exchanger.

[0022] It should be emphasized that the circulating water return port T4 directly communicates with the heated channel in the first plate set.

[0023] What needs to be explained is t...

Embodiment 2

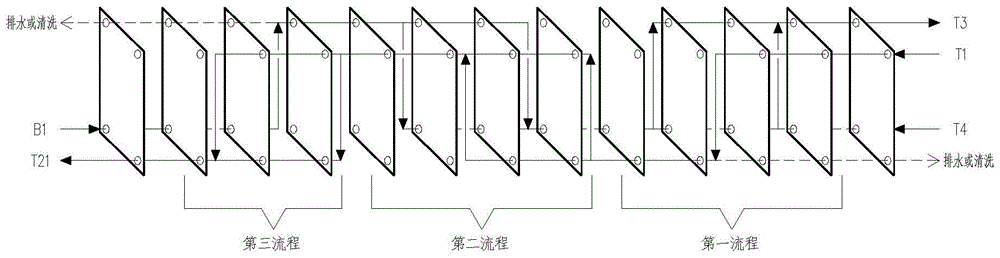

[0028] see image 3 The difference between embodiment 2 and embodiment 1 is that several plate components are 3 groups of plate groups from right to left, which are respectively the first plate group (corresponding to image 3 In the first process), the second plate group (corresponding image 3 In the second process) and the third plate group (corresponding image 3 in the third process).

[0029] Embodiment 2 and Embodiment 1 are only for illustration, and the number of processes can be selected according to the actual situation.

Embodiment 3

[0031] see Figure 4 , compared to Example 1, the heat exchanger in Example 3 is also provided with a pre-heating water inlet T22, which is located on the second plate set and directly connected to the heating in the second plate set Channel connected.

[0032] The heating water flows into the heat exchanger from the heating water inlet T1, and flows out from the heat exchange outlet T21. During the process of flowing in the heat exchanger, the heat in the heating water is gradually transferred to the raw water, and when the heating water is about to reach After heat exchange, when the water outlet T21 is at a low temperature, it cannot effectively provide heat to the raw water at the cold water inlet B1, and the low-grade heating water can be passed through the pre-heating water inlet T22. The heating water first heats the raw water, and when the raw water enters the first channel, it has reached a relatively high temperature, and then heats the raw water through the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com