Low-vacuum heating system coupled with large-temperature-difference heat pump and operation method of heating system

A heating system and large temperature difference technology, applied in heating systems, hot water central heating systems, space heating and ventilation, etc., can solve the problem that the water supply temperature of the secondary network cannot be changed, and large temperature difference heating cannot be effectively used. The water supply temperature of the secondary network cannot be solved, and the effect of improving the heating quality, high practical application value and simple structure is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0030] Example.

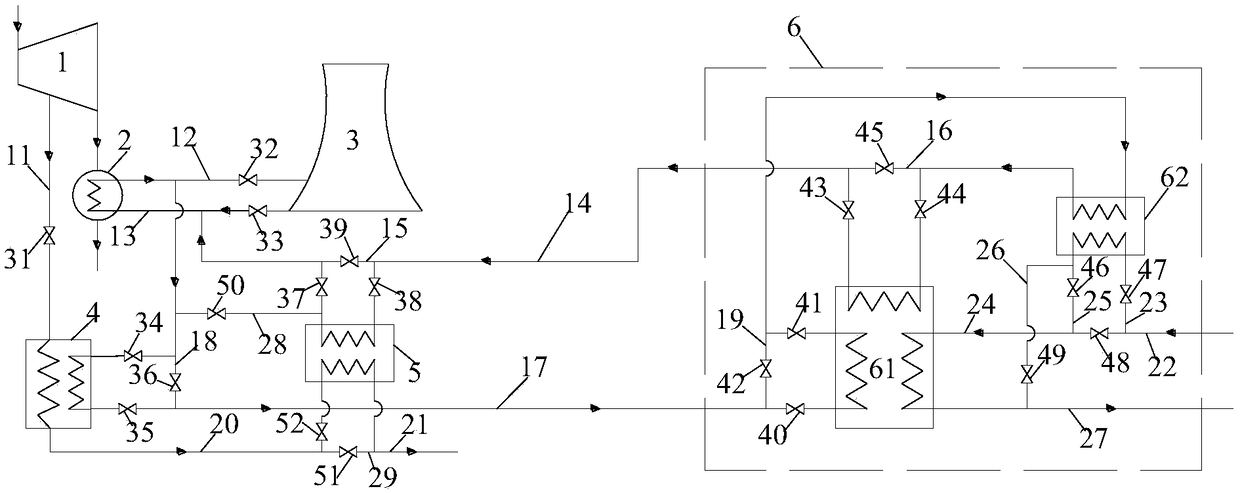

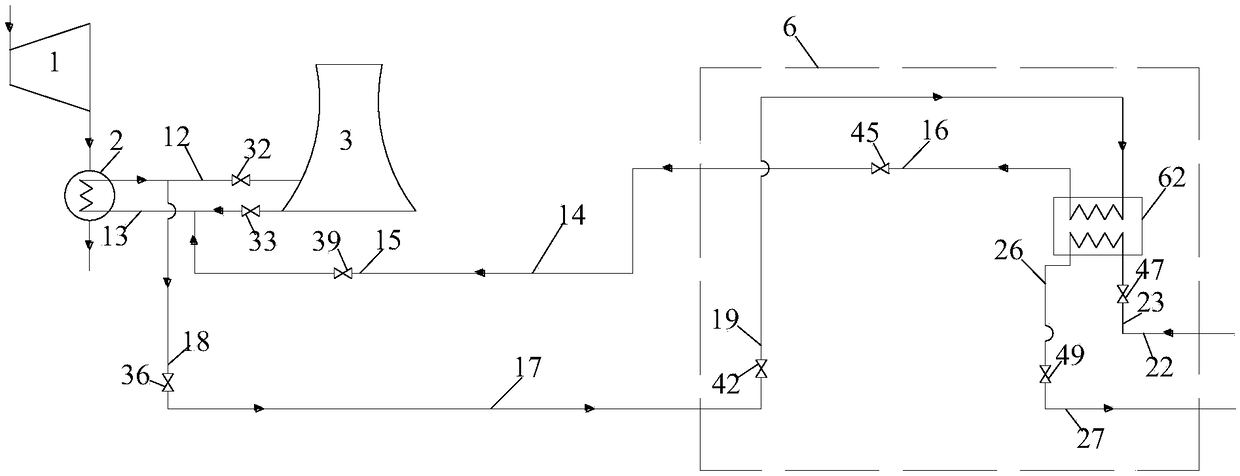

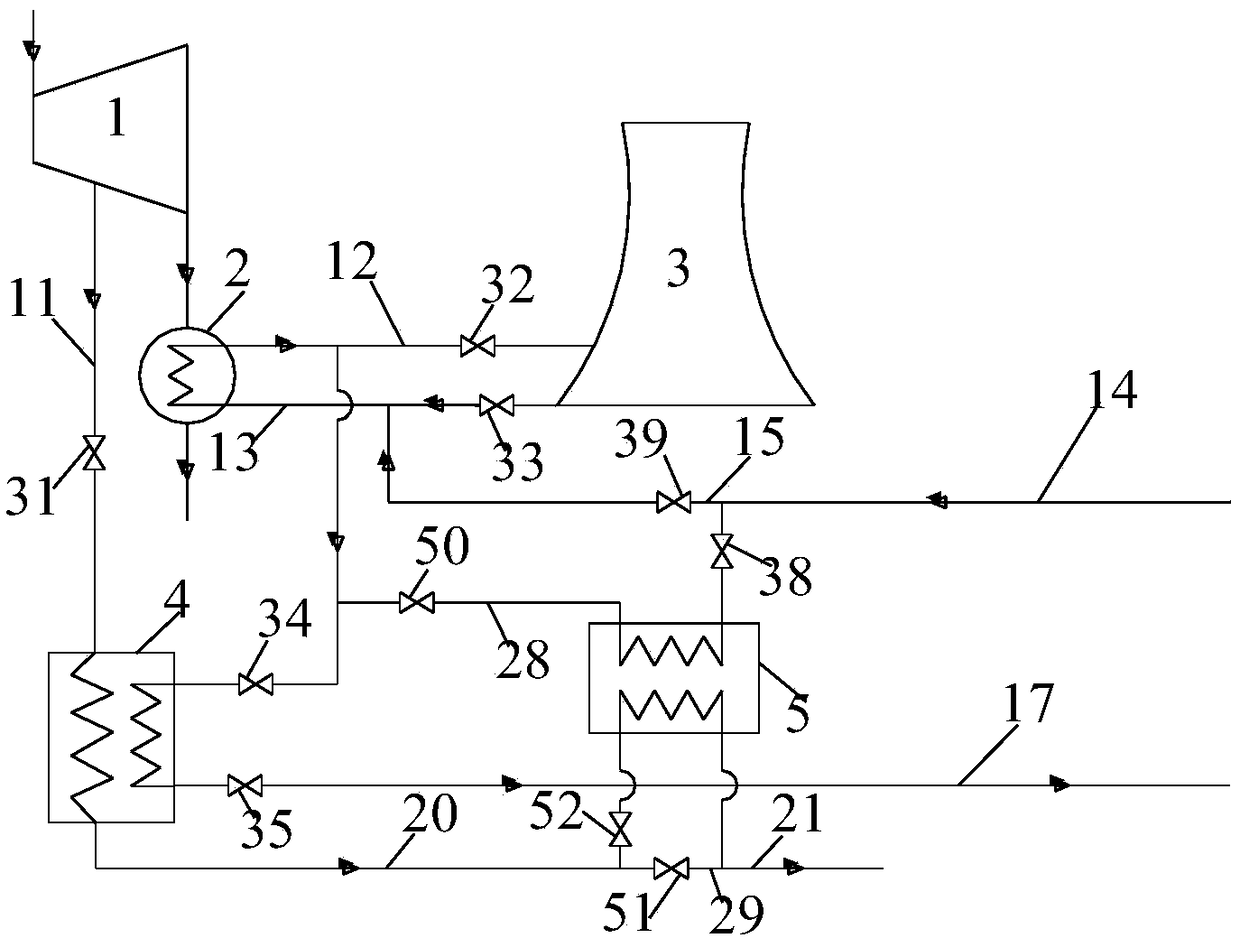

[0031] see figure 1 , the low-vacuum heating system coupled with a large temperature difference heat pump in this embodiment includes: a steam turbine 1, a condenser 2, a cooling tower 3, a heat network heat exchanger 4, a drain heat exchanger 5 and a secondary heat exchange station 6. The secondary heat exchange station 6 includes: a large temperature difference heat pump 61 and a water-to-water heat exchanger 62; the exhaust port of the steam turbine 1 is connected to the condenser 2, and the condenser 3 is connected to the circulating water supply pipe 12 and the circulating water return pipe 13 The cooling tower 3 is connected, and the second valve 32 and the third valve 33 are respectively in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com