Multi-stage heat pump system capable of achieving waste heat recovery in stepped mode

A heat pump system and cascade recovery technology, applied in heat pumps, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as low efficiency, high recovery energy consumption, and complicated maintenance, so as to improve waste heat recovery efficiency and prolong service life , the effect of reducing the compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

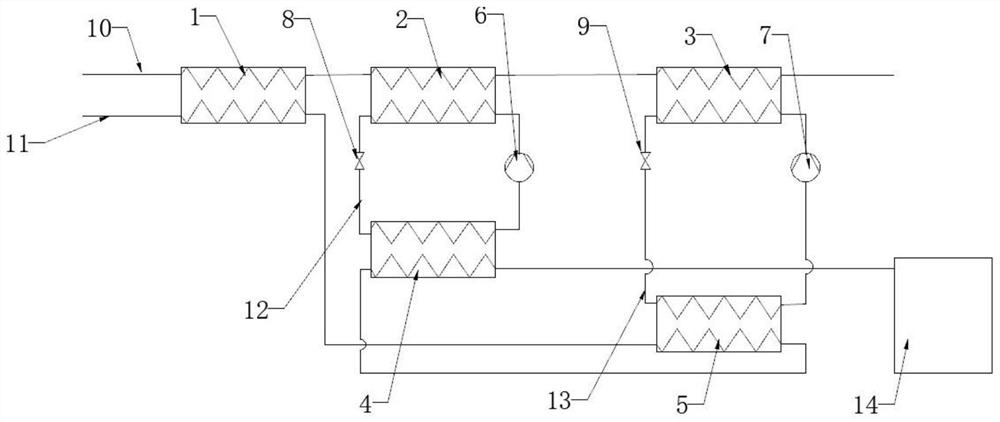

[0021] This embodiment provides a multi-stage heat pump system for cascaded recovery of waste heat, see figure 1 As shown, the sequence includes the first-level unpowered direct heat exchange, the second-level medium-temperature heat pump recovery waste heat heating system, and the third-level high-temperature heat pump recovery waste heat heating system.

[0022] Specifically, the first-stage unpowered heat exchanger 1 is a partition-type direct heat exchanger, one input end of which is connected to the product tap water pipeline 10, and the other input end is connected to the waste heat source drain pipe 11. When heating the product, the partition wall heat exchange is used to directly perform the first step of heat exchange. This stage of heat exchange can realize the initial recovery of part of the heat in the waste heat source without consuming energy.

[0023] Specifically, the first input end of the first-stage unpowered heat exchanger is connected to the water outlet e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com