Winding temperature test system and method

A winding temperature and testing system technology, which is applied in the electrical field, can solve the problem that inverter compressors or inverter motors cannot perform winding testing, and achieve the effect of live testing.

Inactive Publication Date: 2015-08-19

GREE ELECTRIC APPLIANCES INC

View PDF8 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Based on this, it is necessary to provide a winding temperature testing system and method for the problem that the winding test cannot be performed when the variable frequency compressor or variable frequency motor is running

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0048] As a possible implementation of the winding temperature testing system 100 of the present invention, it also includes detection equipment, wherein:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

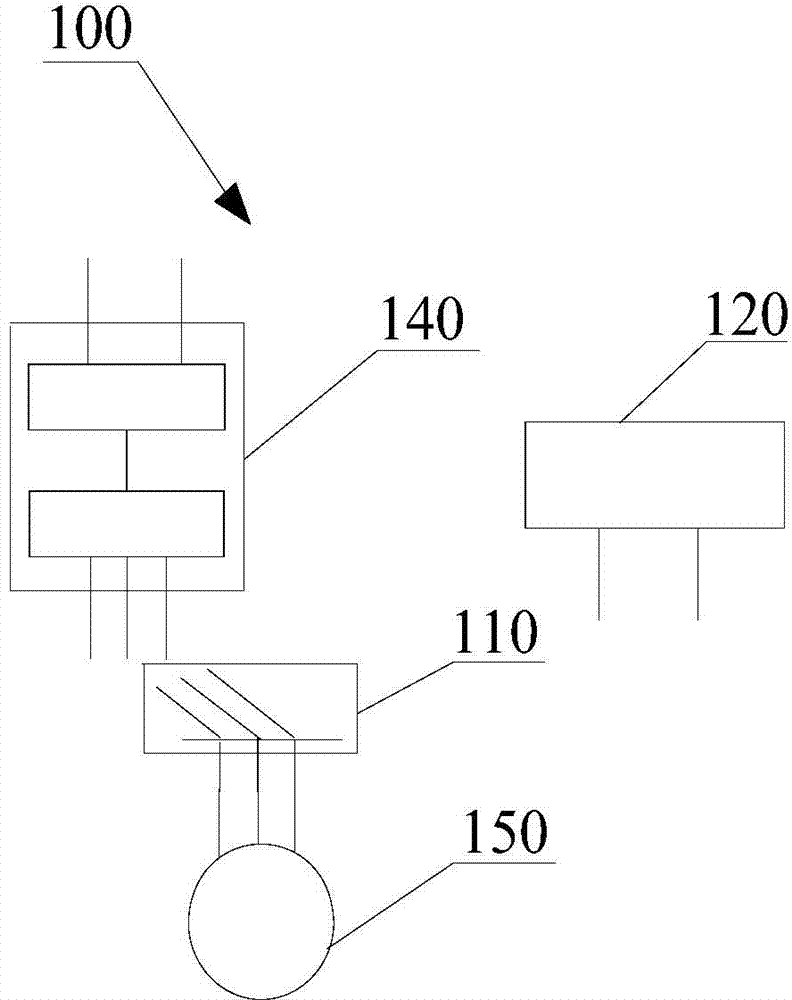

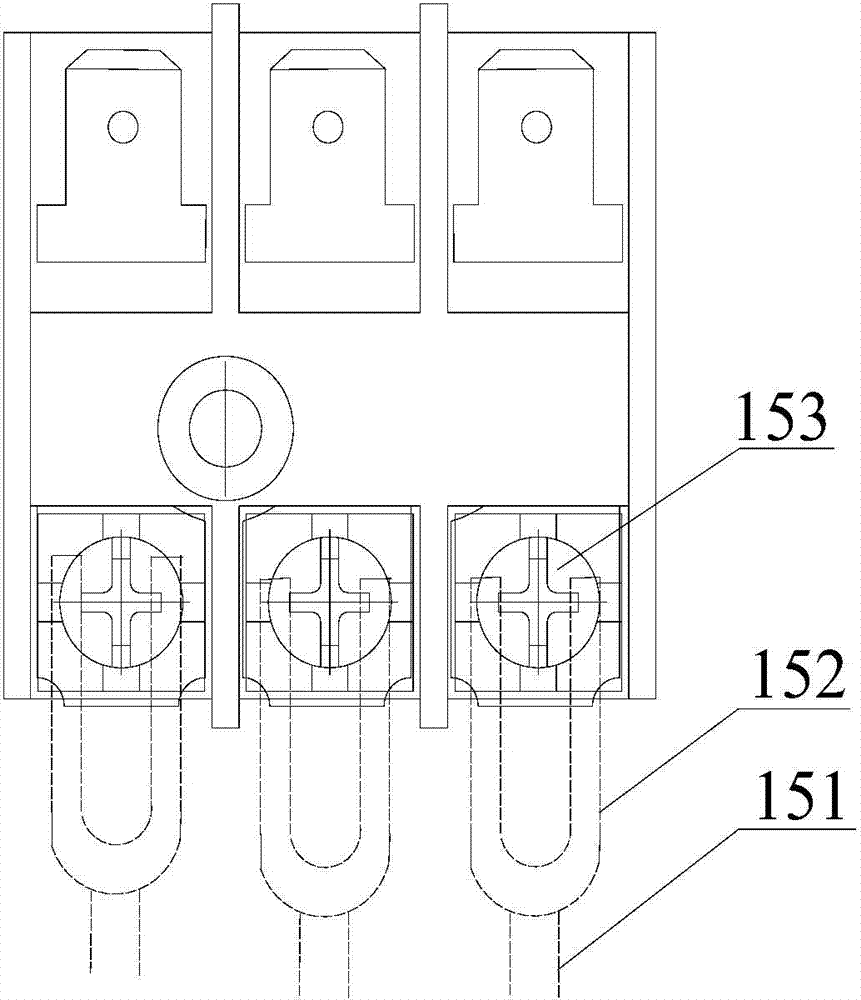

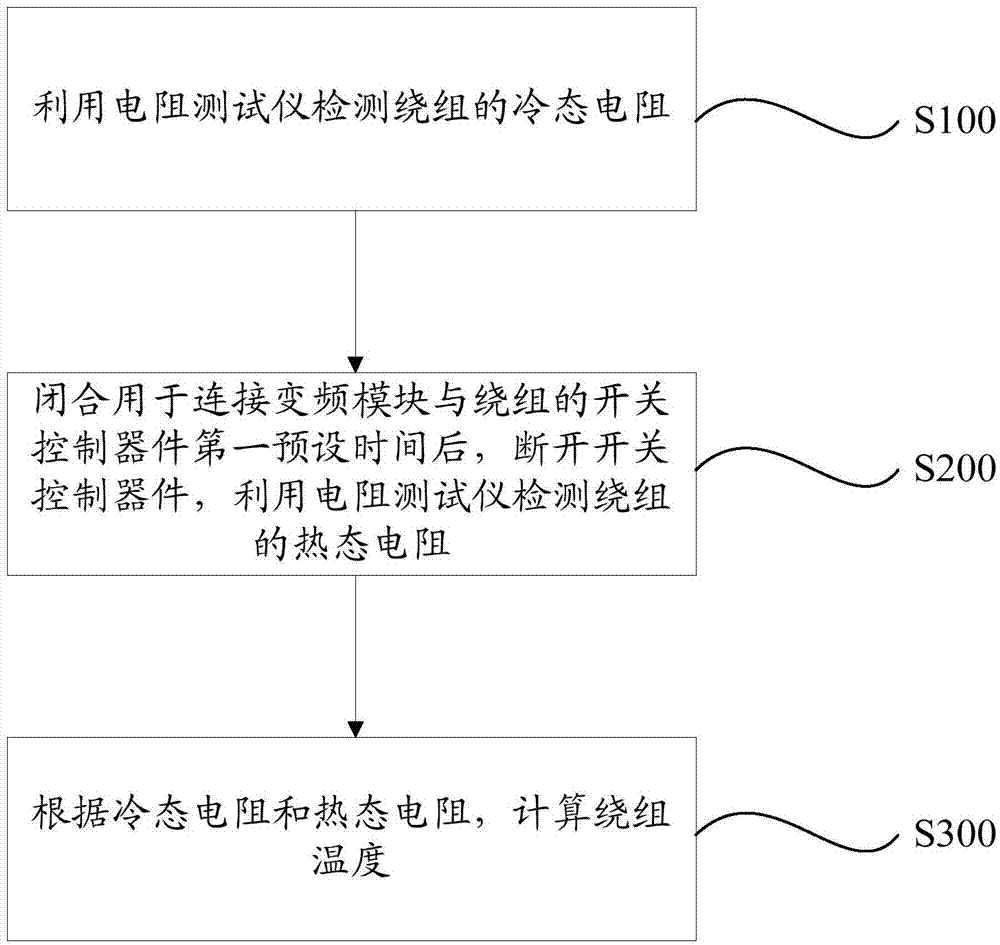

The invention discloses a winding temperature test system and method; the system comprises a switch control device, a resistance tester and a calculation module; one end of the switch control device is connected with an output end of a frequency conversion module, and the other end is connected with an input end of the winding, and the switch control device is sued for controlling connected / disconnected between the frequency conversion module and the winding; the resistance tester is used for testing cold condition resistance of the winding, and detecting thermal state resistance of the winding when the frequency conversion module and the winding are disconnected after the switch control device controls the frequency conversion module and the winding to connect for a first preset time; the calculation module is used for calculating winding temperature according to the cold condition resistance and thermal state resistance. Winding test cannot be realized in frequency conversion compressor or variable frequency motor operations in the prior art, the winding temperature test system and method can solve the problems, and realizes live-line test of the frequency conversion winding.

Description

technical field [0001] The invention relates to the electrical field, in particular to a winding temperature testing system and method. Background technique [0002] The insulation capacity of the variable frequency compressor or variable frequency motor restricts the service life of the variable frequency compressor or variable frequency motor, and the most important factor affecting the insulation capacity of the variable frequency compressor or variable frequency motor is the temperature of the variable frequency compressor or variable frequency motor during operation, and the variable frequency The service life of the compressor or variable frequency motor depends on the life of the insulating material at the highest temperature. This is because the high temperature will cause the polymer chain in the internal insulation material of the winding of the variable frequency compressor or variable frequency motor to heat and fission, and the degree of polymerization will be re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01K7/16

Inventor 祁伟刘桂平林康桂张继勇郑海文舒宏官姜华叶金旺马静黄泽

Owner GREE ELECTRIC APPLIANCES INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com