Preparation method for silicone-acrylic miniemulsion

A technology of mini-emulsion and silicone-acrylate, applied in the field of preparation of silicone-acrylate mini-emulsion, can solve the problems of high price, complicated process, restricting the content of organosilicon in silicone-acrylate mini-emulsion, etc., and achieve the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

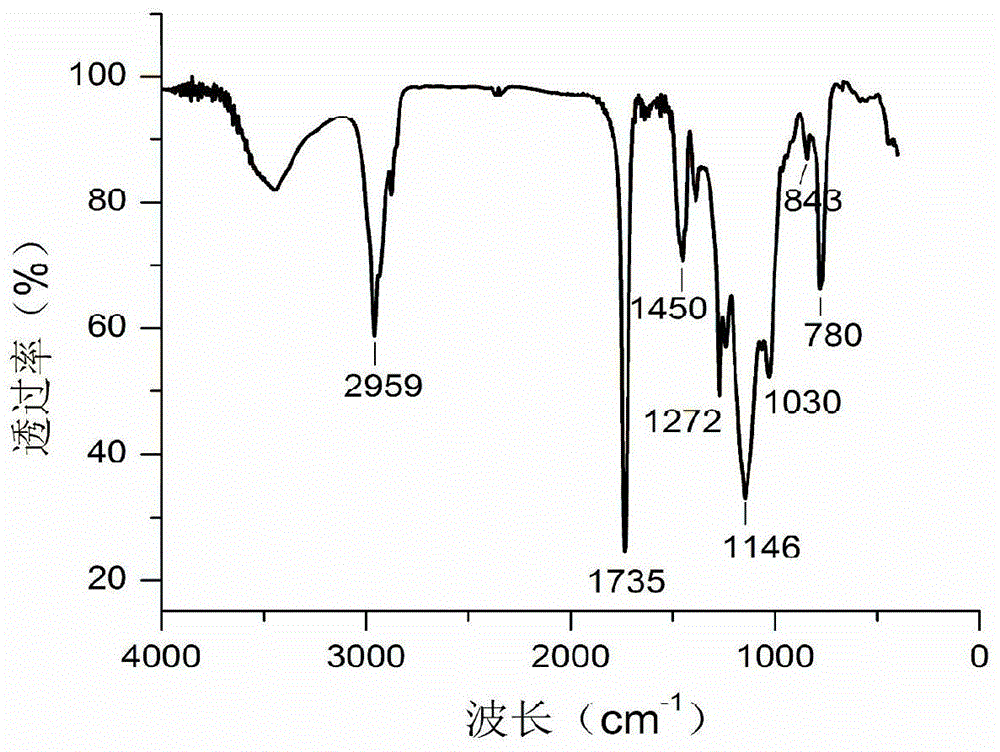

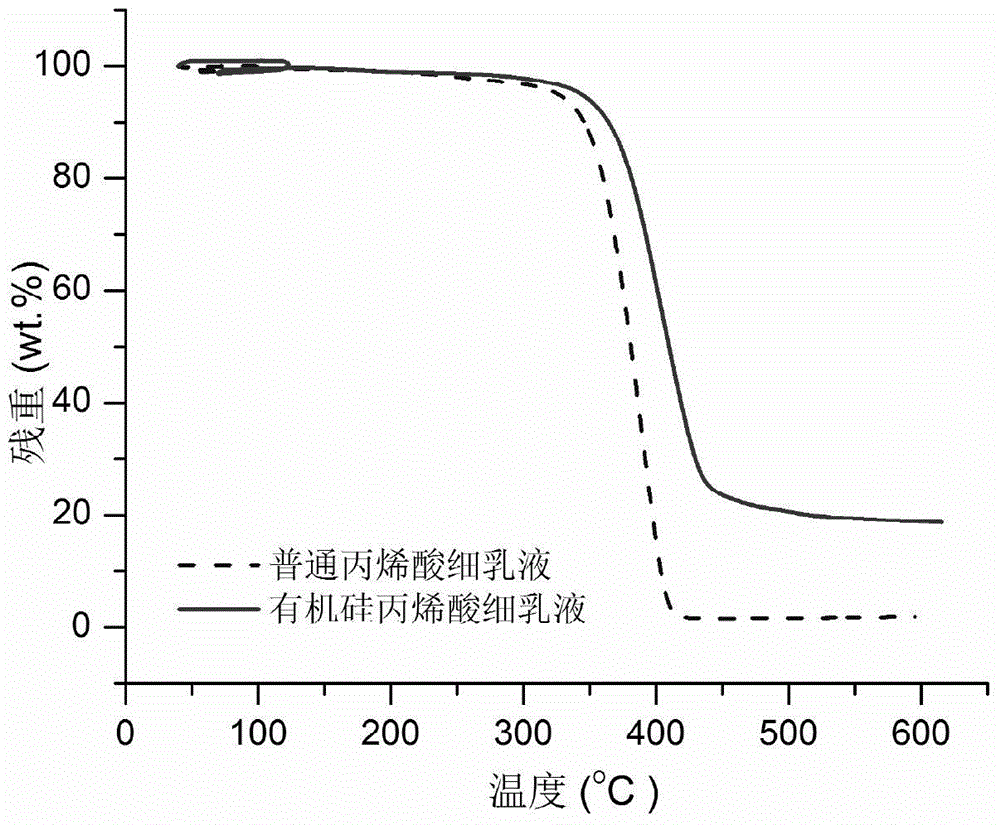

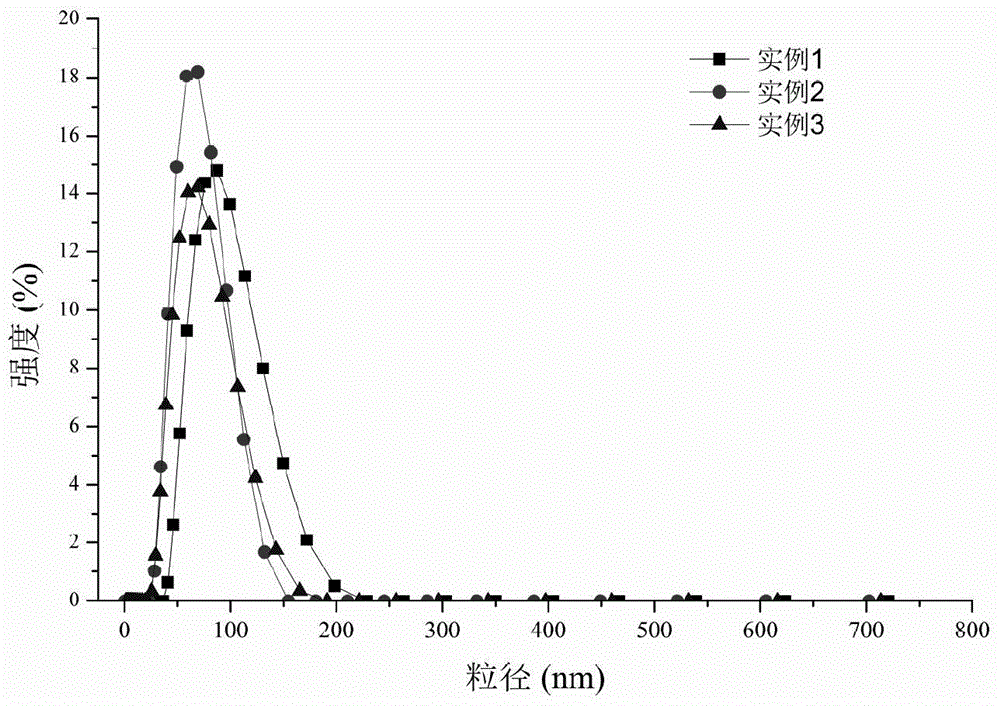

Embodiment 1

[0044] (1) Methyl methacrylate (MMA), butyl acrylate (BA), methyltrimethoxysilane (MTMS) and 3-(methacryloyloxy)propyltrimethoxysilane (MEMO) in moles The ratio of 2:1:0.92:0.08 and 2wt.% (the mass fractions are based on the total monomer mass, the same below) are added to the single-necked flask equipped with magnetic stirring together with hexadecane, and stirred for more than 1 hour to completely dissolve the stabilizer , become the oil phase mixture;

[0045] (2) Add 2.1 wt.% sodium dodecyl sulfate (SDS) and 1.4 wt.% OP-10 together with deionized water whose mass is 1.5 times the total mass of the monomers into a four-necked flask equipped with magnetic stirring , stirred for more than 1 hour to become an aqueous phase mixture;

[0046] (3) the oil phase mixture is gradually added dropwise to the water phase mixture, and the hydrolysis reaction of the organosilicon and the emulsification process of the overall mixture are simultaneously carried out at 30 ° C, and the hydr...

Embodiment 2

[0051] (1) Methyl methacrylate (MMA), butyl acrylate (BA), methyltrimethoxysilane (MTMS) and 3-(methacryloyloxy)propyltrimethoxysilane (MEMO) in moles Ratio 2:1:0.92:0.08 with 1 wt.% hexadecane and 1 wt.% methyl methacrylate-n-butyl acrylate-siloxane random copolymer (Mn=3000 g / mol, PDI=1.11, MMA: BA (mol)=2:1, 3-(methacryloyloxy) propyltrimethoxysilane content is 20mol%) is added to the single-necked flask equipped with magnetic stirring, and stirred for more than 1 hour, so that the stabilizer is completely Dissolved to become an oil phase mixture;

[0052] (2) Add 2.1 wt.% sodium dodecyl sulfate (SDS) and 1.4 wt.% OP-10 together with deionized water whose mass is 1.2 times the total mass of the monomers into a four-necked flask equipped with magnetic stirring , stirred for more than 1 hour to become an aqueous phase mixture;

[0053] (3) the oil phase mixture is gradually added dropwise to the water phase mixture, and the hydrolysis reaction of the organosilicon and the e...

Embodiment 3

[0058] (1) Methyl methacrylate (MMA), butyl acrylate (BA), methyltriethoxysilane (MTES) and 3-(methacryloyloxy)propyltrimethoxysilane (MEMO) according to Molar ratio 2:1:0.71:0.08 with 1 wt.% hexadecane and 1 wt.% methyl methacrylate-n-butyl acrylate-siloxane random copolymer (Mn=3000 g / mol, PDI=1.11, MMA : BA (mol) = 2: 1, 3-(methacryloyloxy) propyl trimethoxysilane content is 20mol%) is added to the single-necked flask equipped with magnetic stirring, and stirred for more than 1 hour to make the stabilizer Completely dissolved to become an oil phase mixture;

[0059] (2) Add 2.1 wt.% sodium dodecyl sulfate (SDS) and 1.4 wt.% OP-10 together with deionized water whose mass is 1.2 times the total mass of the monomers into a four-necked flask equipped with magnetic stirring , stirred for more than 1 hour to become an aqueous phase mixture;

[0060] (3) the oil phase mixture is gradually added dropwise to the water phase mixture, and the hydrolysis reaction of the organosilicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com