Steam generator improvement structure

A steam generator and heating element technology, applied in steam generation, steam generation methods, steam boilers, etc., can solve problems such as soft hoses, abnormal water supply, sagging and folding of hoses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

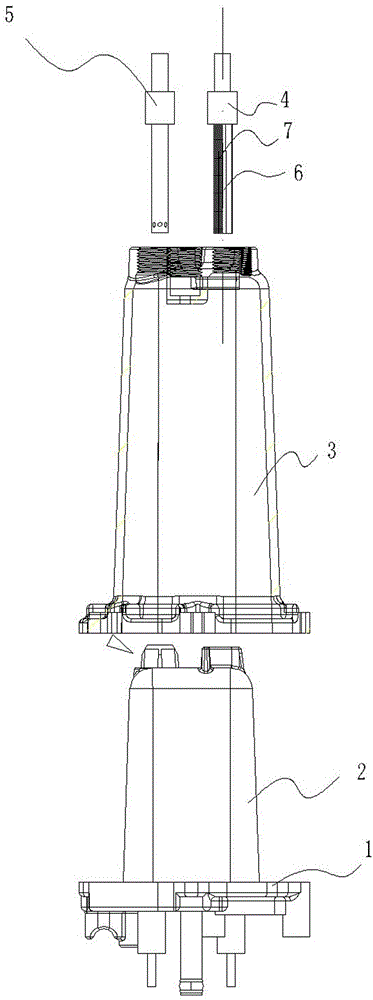

[0010] Embodiment 1: as figure 1 As shown, the present invention includes a columnar heating element 2 with a fixed base plate 1, a casing 3 that is sleeved on the outside of the columnar heating element 2 and fixed on the fixed base plate 1, and the columnar heating element 2 includes a heating wire, and the outer casing 3 that is cast on the heating wire Heat conductor (aluminum), the top of the casing 3 is provided with a water inlet member 4 and a steam outlet member 5, and a hose 6 connected to the water inlet member 4 is arranged inside the casing 3, and the special feature is that the hose 6 is sleeved There is a cylindrical metal net 7 , and one end of the cylindrical metal net 7 is fixed to the water introduction member 4 .

Embodiment 2

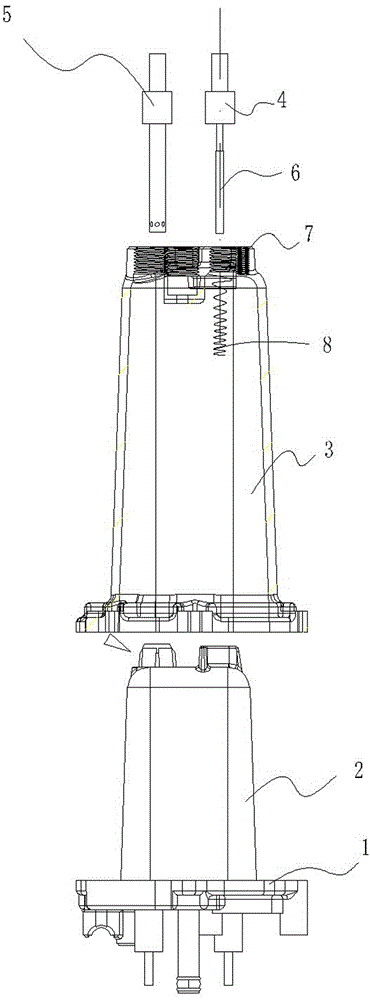

[0011] Embodiment 2: as figure 2 As shown, in this embodiment, on the basis of Embodiment 1, a cylindrical spring ring 8 is used to replace the cylindrical metal mesh 7 , and one end of the cylindrical spring ring 8 is fixed on the inner wall of the top of the housing 3 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap