Floating type wind power device with plastic floating bodies

A floating body and plastic technology, applied in the field of floating wind power devices, can solve problems such as affecting the operation of ships, a large number of anti-corrosion treatments, and self-weight, etc., so as to ensure the safety and practicability of use, reduce maintenance difficulty and cost, and reduce workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

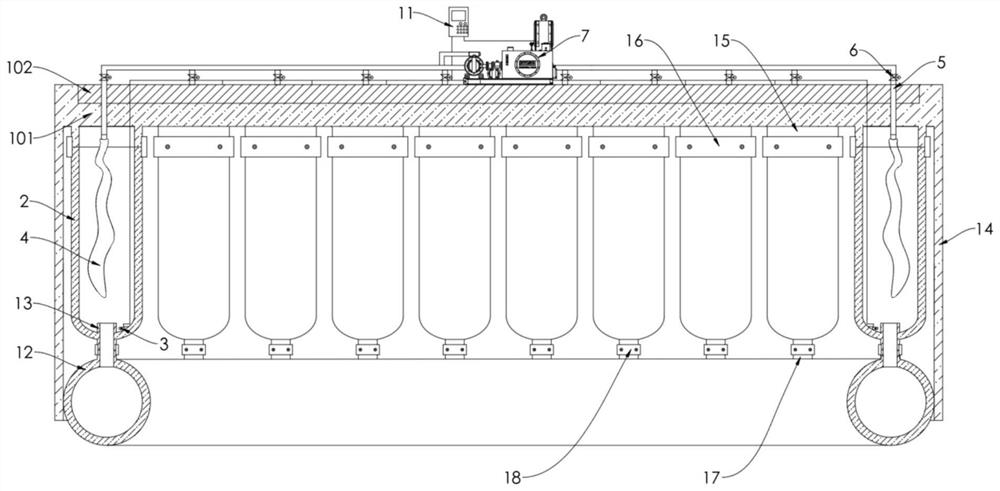

[0031] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

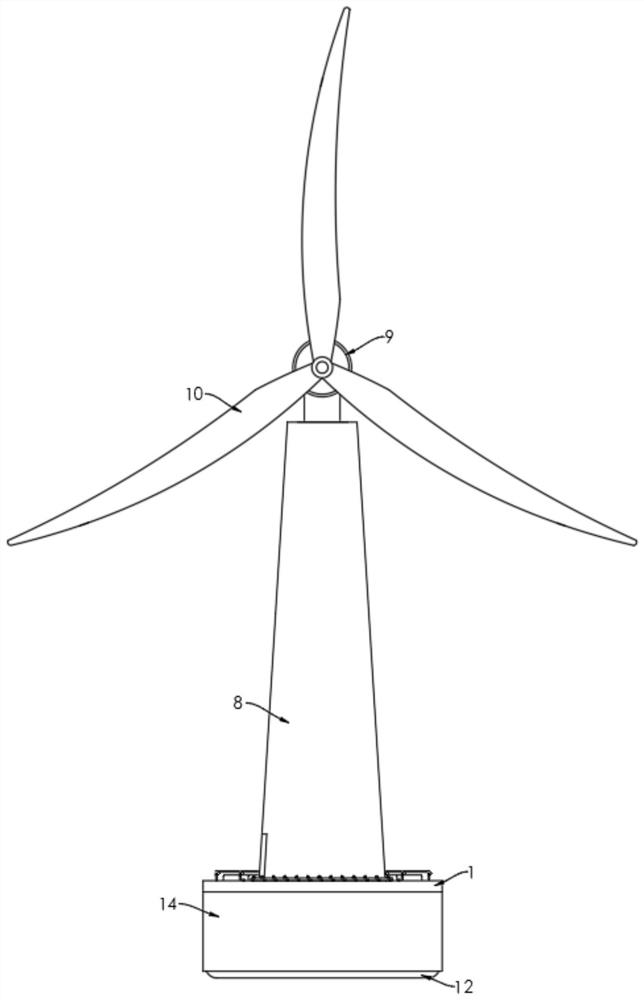

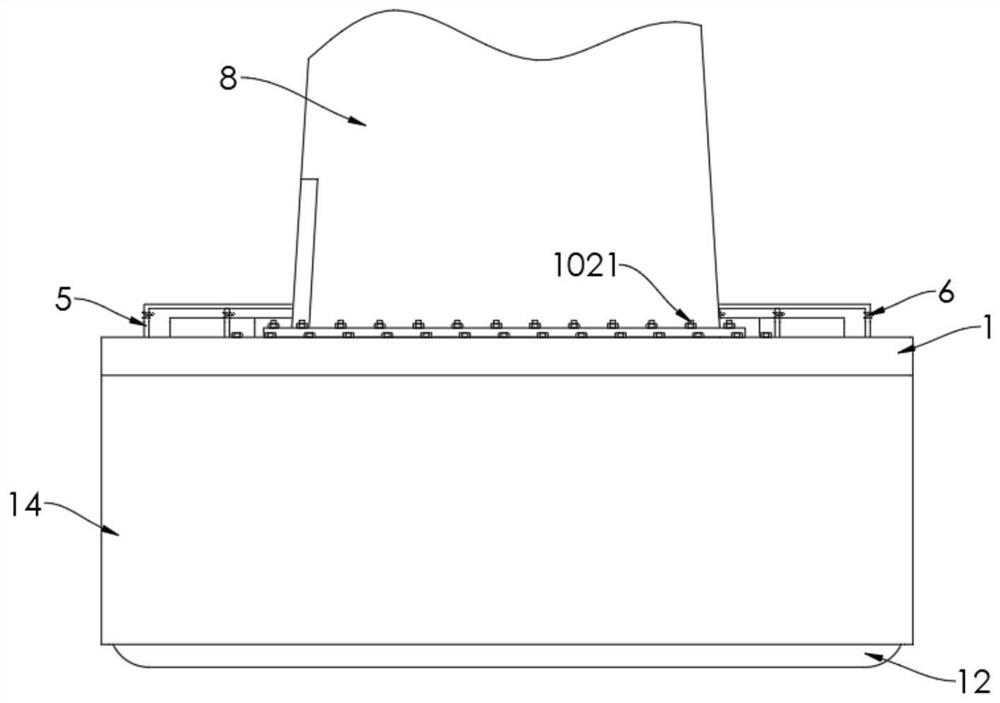

[0032] refer to Figure 1-4 , a floating wind power device with a plastic floating body, comprising

[0033] The floating platform includes a base 1, and a plurality of corresponding plastic floating bodies 2 are evenly sealed and connected downwards on the periphery of the base 1, and the bottoms of the plastic floating bodies 2 are respectively provided with corresponding water immersion sensors 3;

[0034] Protective plate 14, the base 1 includes a sheet-shaped plastic plate 101, the protective plate 14 is integrally formed and connected to the lower side of the sheet-shaped plastic plate 101, and the protective plate 14 is surrounded by the plastic floating body 2 outside of

[0035] A plurality of supporting airbags 4 are respectively arranged in the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap