Multi-cell automobile energy-absorbing buffer device

A buffer device, automobile technology, applied in vehicle parts, transportation and packaging, vehicle safety arrangement, etc., to achieve the effect of improving energy absorption efficiency, increasing flexibility, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

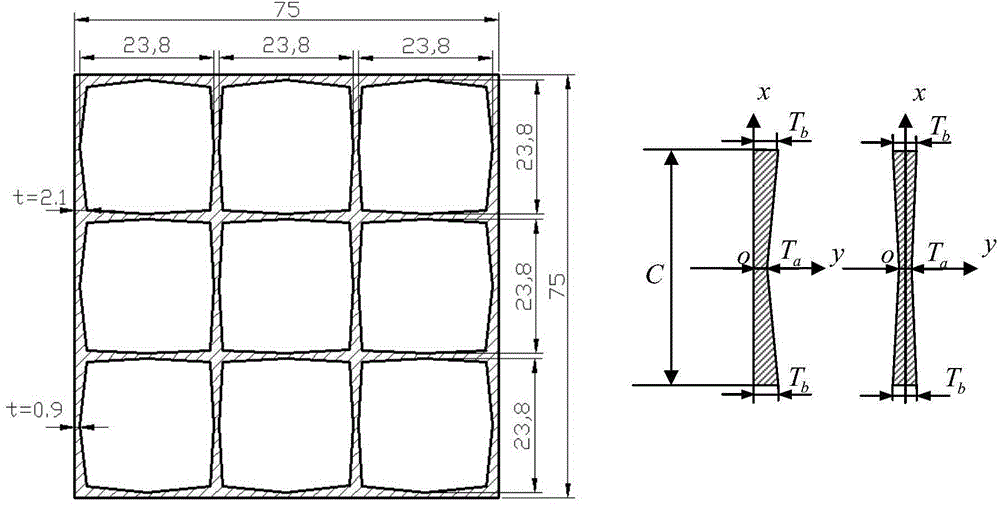

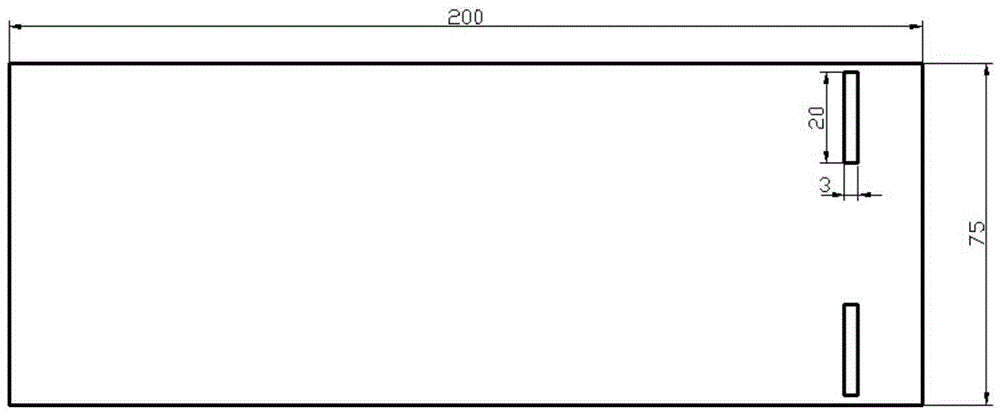

[0034] like Figure 1-3 As shown, in this embodiment, the buffer energy-absorbing device is composed of a nine-cell gradient square thin-walled tube (2), a front-end mounting plate (1) and a rear-end mounting plate (3). The main structure of the buffer energy-absorbing device in this embodiment—the multi-cell energy-absorbing tube 2 adopts a nine-cell gradient square thin-walled energy-absorbing buffer structure. Metal preparation. The dimensions of the cross-section of the gradient square thin-walled tube are as figure 2 as shown, figure 2 The unit of each dimension is mm. The nine-cell gradient square thin-walled tube is connected to the bumper through the front-end mounting plate 1, and connected to the front longitudinal beam through the rear-end mounting plate 2.

[0035] In this embodiment, the nine-cell gradient square thin-walled tube has an axial length of 200 mm, an external dimension of the cross section of 75 mm×75 mm, and an equivalent thickness of the tube ...

Embodiment 2

[0048] Image 6 A schematic diagram of the three-dimensional structure of another buffer energy-absorbing device of the present invention is shown. The corner cell structures are connected by 4 thin-walled connecting plates, thus forming 4 corner cell structures and the central cavity cell structure, that is, the five-cell structure, such as Image 6 shown. The corner cells and the central cavity cell structure are extruded from light alloy materials at one time, and are connected to the bumper through the front mounting plate, and the rear mounting plate is connected to the front longitudinal beam. A series of induction grooves are set 15mm away from the collision end. The specific size is as Image 6 , 7 shown. The setting of induction tanks is different from that of traditional induction tanks in that they are arranged at intervals rather than continuously. The main purpose lies in two aspects: first, to reduce the peak force of the initial collision; second, to guide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com