Steel tube conveying device

A technology of conveying device and steel pipe, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of surface damage of steel pipe, severe collision and wear of steel pipe, large energy consumption, etc., and achieves the effect of simple operation, reasonable design and guarantee of integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

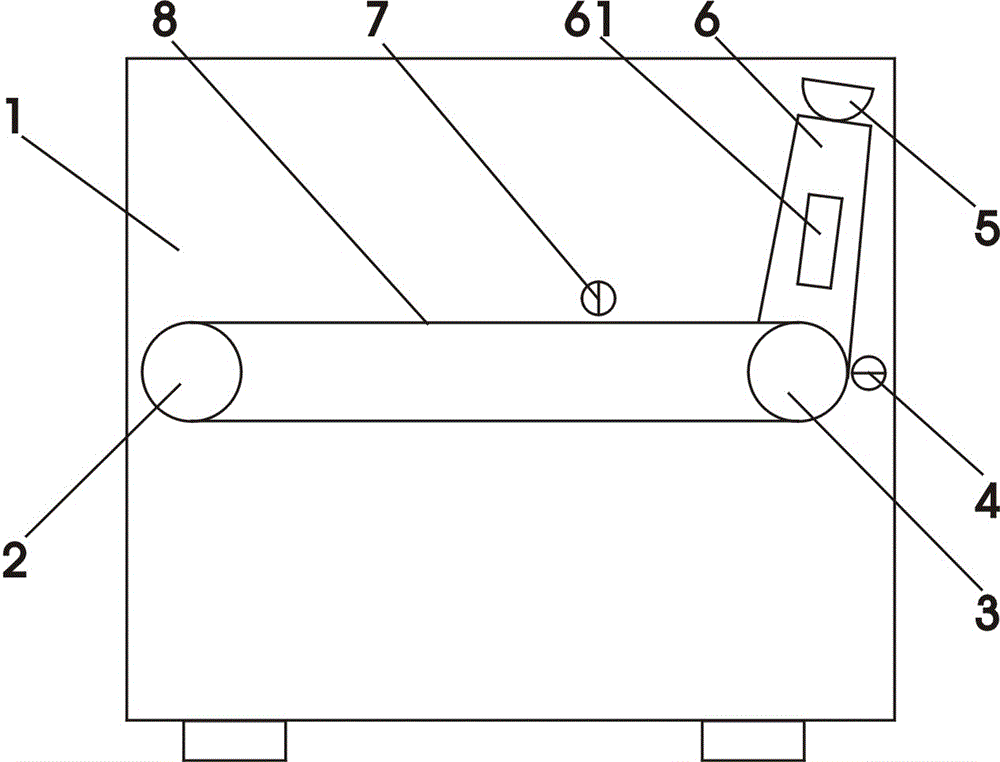

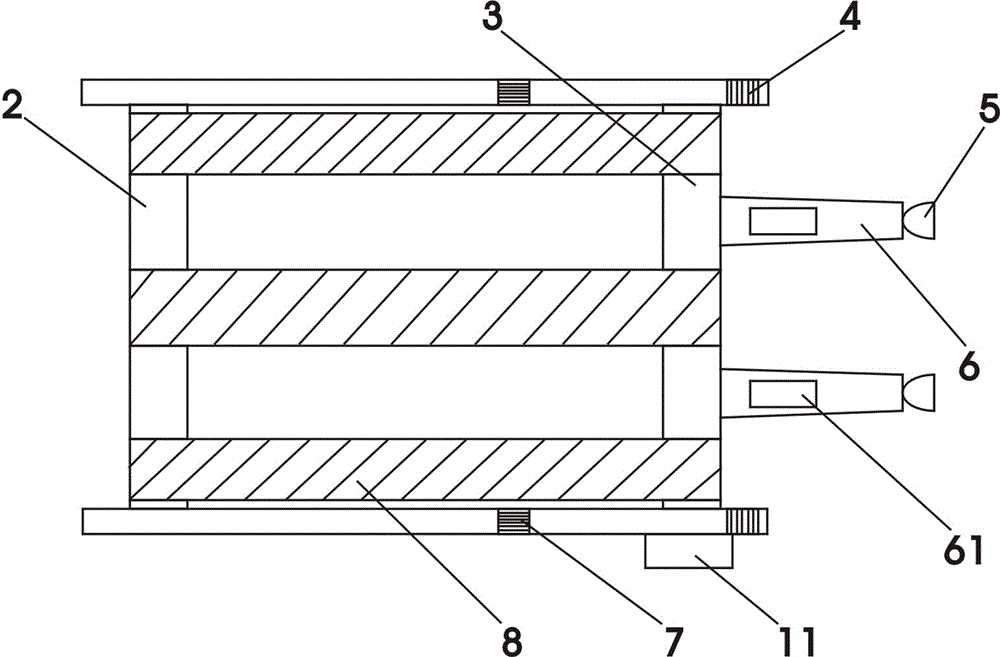

[0008] Now refer to the attached figure 1 And attached figure 2 , combined with specific embodiments as follows: A steel pipe transmission device according to the present invention includes a housing 1, a rotating motor 11, a driven wheel 2, a driving wheel 3, an air suction sensor 4, a vacuum suction cup 5, and a boom 6 , a vacuum generator 61, an inflatable sensor 7 and a transmission belt 8, the housing 1 is the main part of a steel pipe transmission device according to the present invention, an inlet is provided on one side of the housing 1, and one end of the inlet is At the feed end, an outlet is provided on the side opposite to the housing 1, and one end of the outlet is the discharge end, and a driving wheel 3 is arranged at the feeding end, and the driving wheel 3 is perpendicular to the inner surface of the housing 1 , the driving wheel 3 rotates counterclockwise, the driving wheel 3 runs through the inside and outside of the casing 1, a boom 6 is vertically connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com