Prestressed loam wall and construction process thereof

A construction technique, rammed earth wall technology, applied in the field of construction and reinforcement of traditional residential buildings, to achieve the effects of high construction safety, wide application range, and convenient materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings.

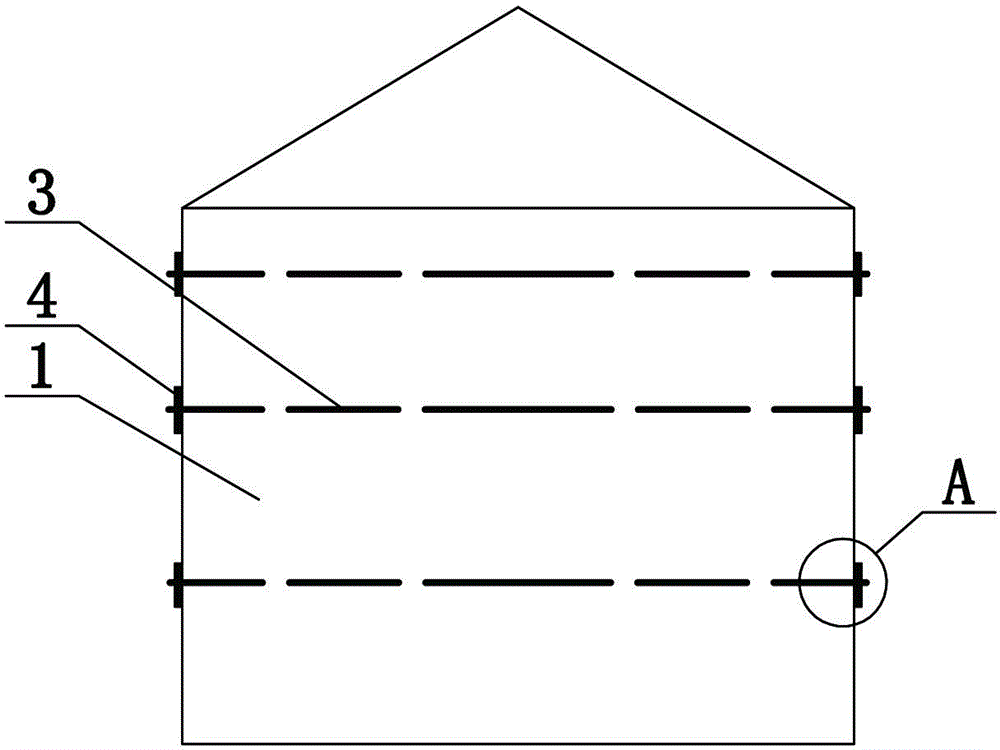

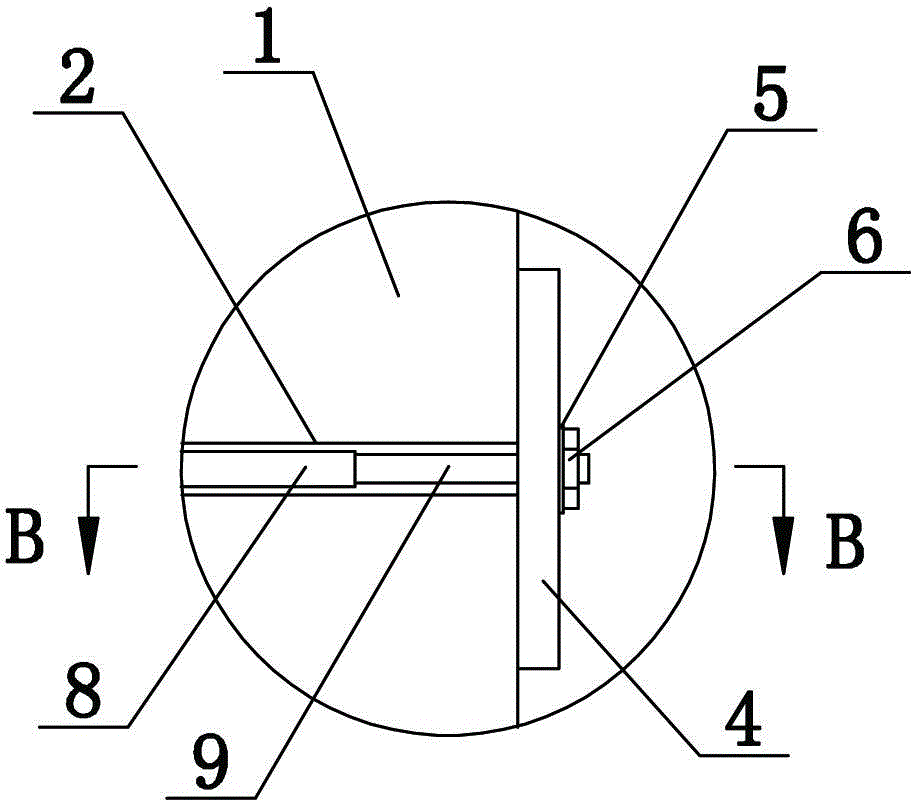

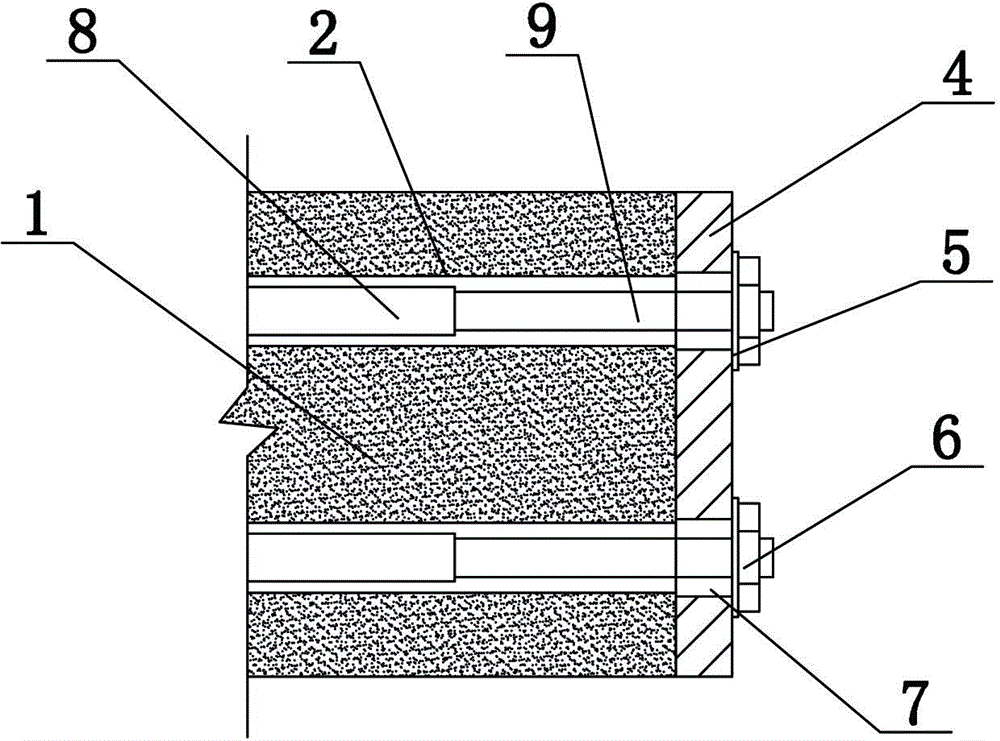

[0045] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a prestressed rammed earth wall includes a wall 1, a casing 2, a prestressed steel bar 3, a fixing plate 4, a washer 5 and a lock nut 6, and the wall 1 is a rammed earth wall 1 , the wall 1 is provided with a casing 2, the casing 2 is a steel casing 2, the casing 2 is arranged along the length direction of the wall 1, and runs through the entire wall 1, the casing 2 is provided with a prestressed steel bar 3, and the wall Both sides of the body 1 are respectively provided with fixing plates 4, two ends of the prestressed steel bars 3 are provided with threads, and the two ends of the prestressed steel bars 3 respectively pass through two fixing plates 4, and are fixed to the fixing plates 4 by washers 5 and lock nuts 6. The fixed plate 4 is a quadrilateral steel plate, its height is 300mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com