Connecting structure of lamp body and lamp pole

A technology of connecting structure and lamp body, which is applied to the parts of lighting devices, lighting devices, outdoor lighting, etc., can solve the problems of affecting stability, not long service life, and poor use effect of the installation tube at the rear of the street lamp, and achieves high reliability. The effect of stable force and improved impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

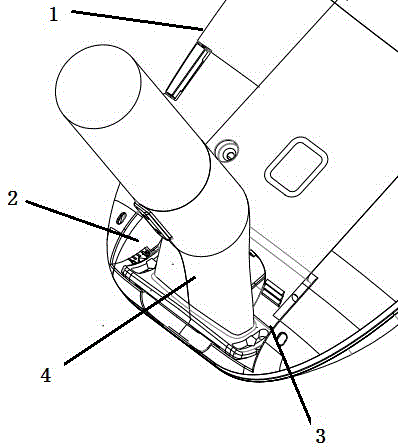

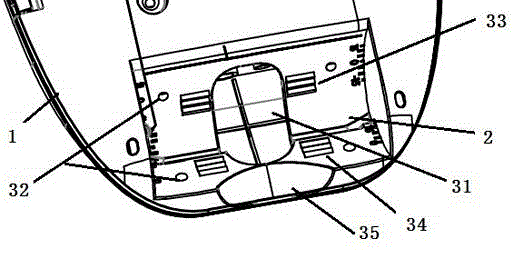

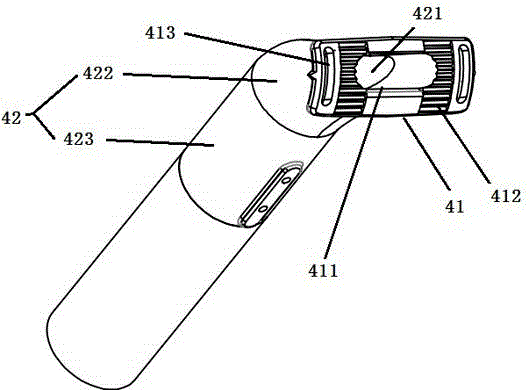

[0021] Such as Figure 1-3 , The connecting structure of the lamp body and the lamp pole of the present invention includes a concave portion 2, a connecting base 3, and a connecting rod 4. The concave portion 2 is provided on the outside of the lamp body 1, for example, on the front of the lamp body 1, that is, the side facing the ground, the connecting base 3 is provided in the concave portion 2, and the connecting rod 4 is connected to the The base 3 is connected in an adjustable angle. This arrangement hides the structure of the connecting base 3, which is beneficial to the appearance of the lamp body. At the same time, the connecting rod 4 interacts with the connecting base 3, and the force is applied to the connecting base 3, that is, to the lamp body 1. The above is beneficial to the stable connection between the connecting rod 4 and the connecting base 3. In addition, it is also convenient for the operator to install and adjust the angle of the lamp body.

[0022] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com