Combined cooling and heating integrated machine with double evaporators

A technology of combined cooling and heating and dual evaporators, applied in the direction of refrigerators, machine operation modes, compressors, etc., can solve the problems of small cooling load and large heating load, and achieve high-efficiency operation, improve work efficiency, and shorten operation. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

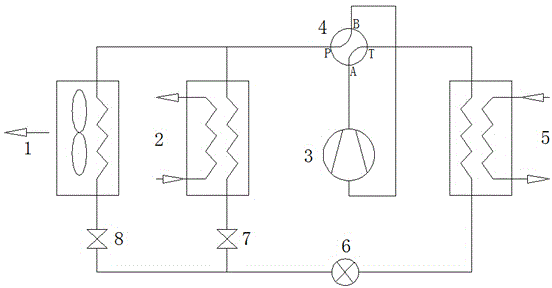

[0026] Embodiment 1: as figure 1 As shown, a dual evaporator cooling and heating integrated machine includes evaporator I1, evaporator II2, compressor 3, four-way reversing valve 4, casing condenser 5, throttling device 6, and valve I7 , valve II8; one end of the evaporator I1 is connected to the valve II8, and the other end of the evaporator I1 is respectively connected to the P port of the evaporator II2 and the four-way reversing valve 4; one end of the evaporator II2 is connected to the valve I7, and the evaporation The other end of the device II2 is connected to the P port of the four-way reversing valve 4; specifically, the P port of the evaporator I1, the evaporator II2 and the four-way reversing valve 4 are connected with a three-way connection; the outlet of the throttling device 6 is connected to the valve Ⅰ7, valve Ⅱ8 adopts three-way connection;

[0027] The A port of the four-way reversing valve 4 is connected with the suction port of the compressor 3, the gas ou...

Embodiment 2

[0029] Embodiment 2: as figure 1 As shown, a dual evaporator cooling and heating integrated machine includes evaporator I1, evaporator II2, compressor 3, four-way reversing valve 4, casing condenser 5, throttling device 6, and valve I7 , valve II8; one end of the evaporator I1 is connected to the valve II8, and the other end of the evaporator I1 is respectively connected to the P port of the evaporator II2 and the four-way reversing valve 4; one end of the evaporator II2 is connected to the valve I7, and the evaporation The other end of the device II2 is connected to the P port of the four-way reversing valve 4; specifically, the P port of the evaporator I1, the evaporator II2 and the four-way reversing valve 4 are connected with a three-way connection; the outlet of the throttling device 6 is connected to the valve Ⅰ7, valve Ⅱ8 adopts three-way connection;

[0030] The A port of the four-way reversing valve 4 is connected with the suction port of the compressor 3, the gas ou...

Embodiment 3

[0033] Embodiment 3: as figure 1As shown, a dual evaporator cooling and heating integrated machine includes evaporator I1, evaporator II2, compressor 3, four-way reversing valve 4, casing condenser 5, throttling device 6, and valve I7 , valve II8; one end of the evaporator I1 is connected to the valve II8, and the other end of the evaporator I1 is respectively connected to the P port of the evaporator II2 and the four-way reversing valve 4; one end of the evaporator II2 is connected to the valve I7, and the evaporation The other end of the device II2 is connected to the P port of the four-way reversing valve 4; specifically, the P port of the evaporator I1, the evaporator II2 and the four-way reversing valve 4 are connected with a three-way connection; the outlet of the throttling device 6 is connected to the valve Ⅰ7, valve Ⅱ8 adopts three-way connection;

[0034] The A port of the four-way reversing valve 4 is connected with the suction port of the compressor 3, the gas out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com