Butadiene extraction process

A butadiene and butene technology, applied in the field of butadiene extraction, can solve the problems of lower yield, low overall yield, and loss of 1,3-butadiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

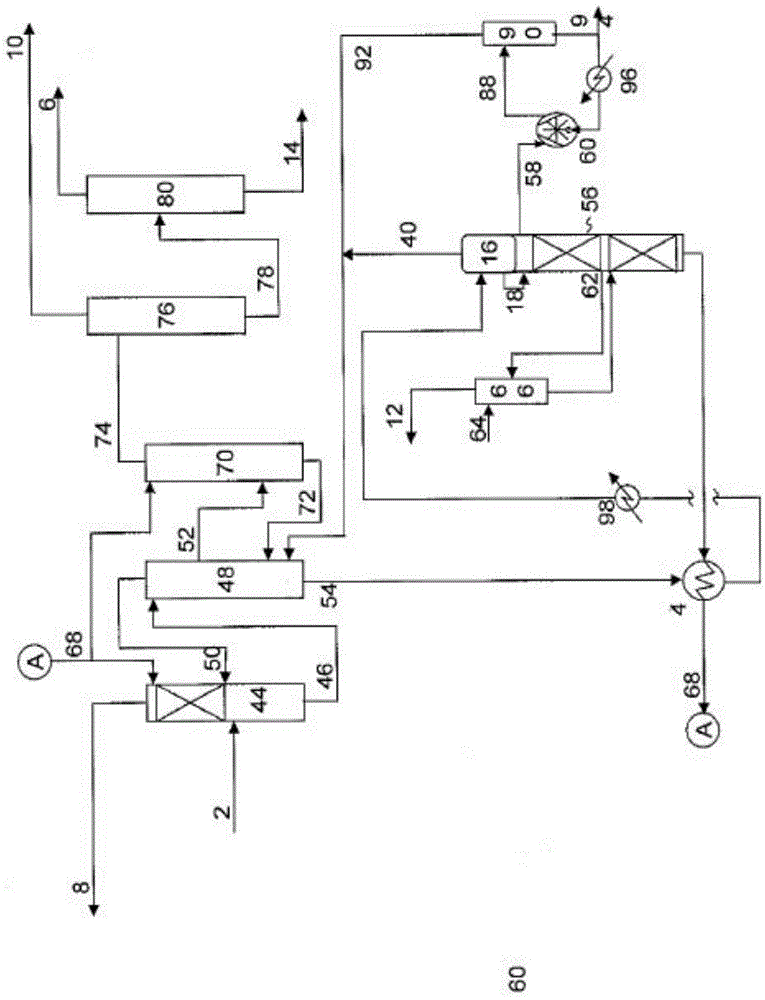

[0048] According to the embodiments disclosed herein, with image 3 A similar butadiene recovery process is shown, with conventional butadiene recovery (utilizing screw-type or centrifugal compressors and cooling towers) and compressorless butadiene recovery (also involving cooling towers) utilizing the following conditions for comparison.

[0049] For the no-compressor design, the degassing tower is at 4.21kg / cm 2 Operate under the top pressure of the tower, slightly higher than the pressure of the extractive distillation system (main scrubber, rectifying column and post scrubber). Consequently, the degassing column operates at correspondingly higher temperatures: 148°C at the top and 193°C at the bottom.

[0050] For conventional methods, the degassing tower only has 0.7kg / cm 2 It operates at a higher overhead pressure and at much lower temperatures: 105°C top and 149°C bottom.

[0051] For this example, if image 3 The illustrated embodiment uses a straight-through co-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com