A sleeve off-line device

A sleeve and off-line technology is applied in the field of auxiliary disassembly of sleeves when rolling thin metal strips, which can solve the problems of discontinuous rolling process, low efficiency, and poor safety, so as to ensure process continuity and avoid manpower Operational, Productivity and Safety Effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

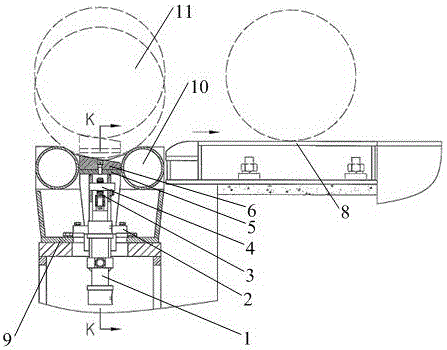

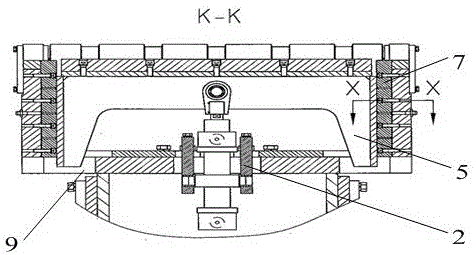

[0026] In order to overcome the problems of discontinuous rolling process, poor safety and low efficiency, the present invention provides such figure 1 , figure 2 , image 3 The shown sleeve off-line device realizes automatic control of sleeve off-line, avoids manual operation, improves production efficiency and safety, and ensures process continuity.

[0027] It includes the trolley roller support 9 and the idler roller 10 arranged symmetrically on the upper end of the trolley roller support 9. The middle of the trolley roller support 9 is fixed with an oil cylinder support 2, and the oil cylinder support 2 is provided with a push sleeve oil cylinder. 1. An oil cylinder earring 3 is connected above the push sleeve oil cylinder 1, and an inclined plane backing plate 6 is connected above the oil cylinder earring 3, and the inclined plane backing plate 6 is located between two idlers 10.

[0028] There is an oil cylinder support 2 fixed in the middle of the trolley roller sup...

Embodiment 2

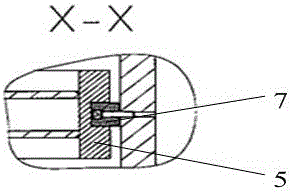

[0035] On the basis of Embodiment 1, the slider 7 in this embodiment is fixed on the trolley roller support 9 by bolts.

[0036] The sliding frame 5 is fixedly connected with the inclined-plane backing plate 6 by bolts.

[0037] The oil cylinder support 2 is fixedly connected with the trolley roller support 9 by bolts.

[0038] It also includes a sleeve collection platform 8, the sleeve collection platform 8 is located on the right side of the trolley roller support 9, and the sleeve collection platform 8 is flush with the highest point of the idler roller 10 on the trolley roller support 9.

[0039] Including trolley roller support 9 and push sleeve oil cylinder 1, the center of said trolley roller support 9 is fixed with oil cylinder support 2, push sleeve oil cylinder 1 is fixed on trolley roller support 9 through oil cylinder support 2 , the upper end of the trolley idler support 9 is symmetrically provided with idler rollers 10 .

[0040] The oil cylinder earring 3 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com