Double-self-centering peripheral float clamping mechanism

A floating clamping and self-centering technology, which is applied in the direction of clamping, positioning devices, metal processing machinery parts, etc., can solve the problems of end face depth deviation, rising waste cost, complex internal structure, etc., achieve stable positioning, improve efficiency, Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

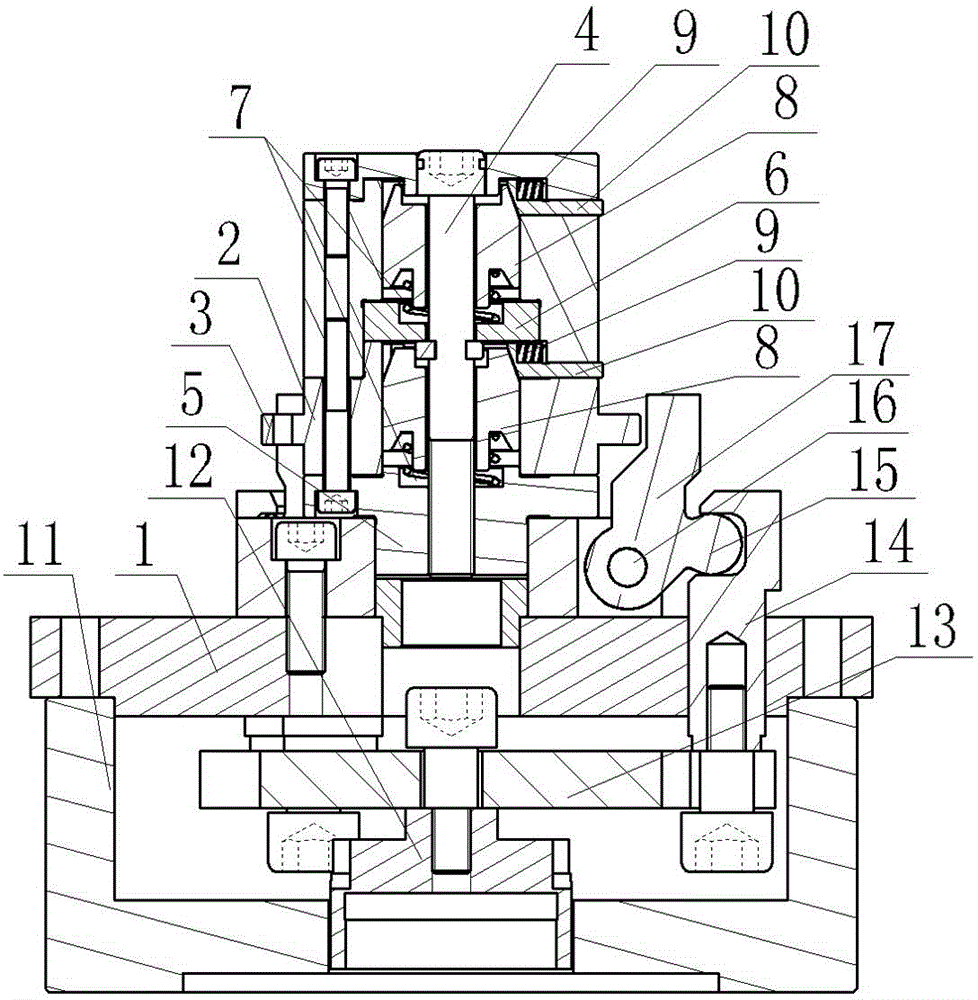

[0010] See figure 1 As shown, a double self-centering outer circle floating clamping mechanism includes a base 1, a mandrel intermediate seat 2 is installed on the base 1, an annular boss 3 is arranged on the outer side of the mandrel intermediate seat 2, and the mandrel intermediate seat 2 A bolt 4 is installed inside, the lower end of the bolt 4 is threadedly connected to the positioning mandrel 5, and the bolt 4 is covered with two layers of positioning devices, and a partition 6 is arranged between the two layers of positioning devices to play the role of separating the two layers of positioning devices. The device includes a cylindrical compression spring 7 and a shaft sleeve 8 set on the bolt 4, a movable positioning piece 10 connected with the mandrel middle seat 2 through the top pressure spring 9, the cylindrical compression spring 7 is arranged at the lower end of the shaft sleeve 8, and the movable positioning piece 10 is arranged On the upper end of the shaft sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com