Precision part assembly device with the function of managing and controlling dimensions

A technology for assembling devices and precision parts, which is applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of very tired assembly personnel, high assembly labor intensity, low assembly accuracy, etc., and achieve the reduction of assembly personnel requirements , Reduce the labor intensity of assembly and stabilize the control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

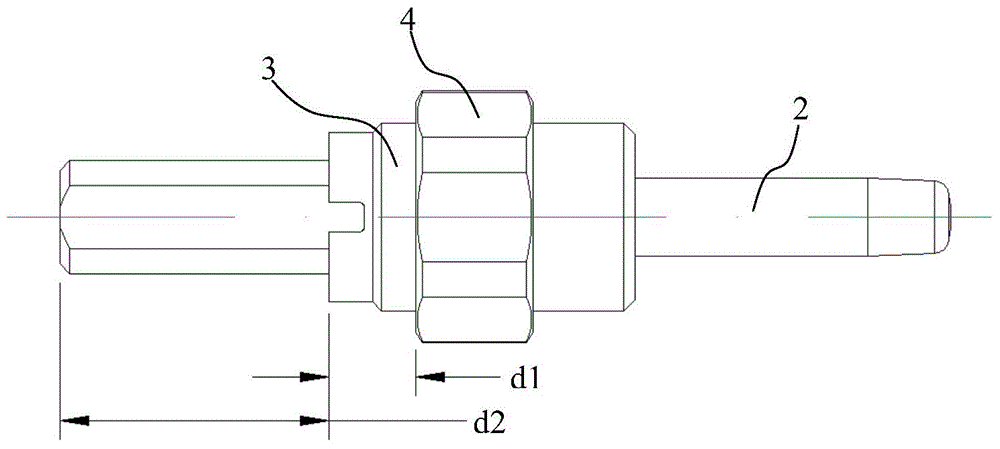

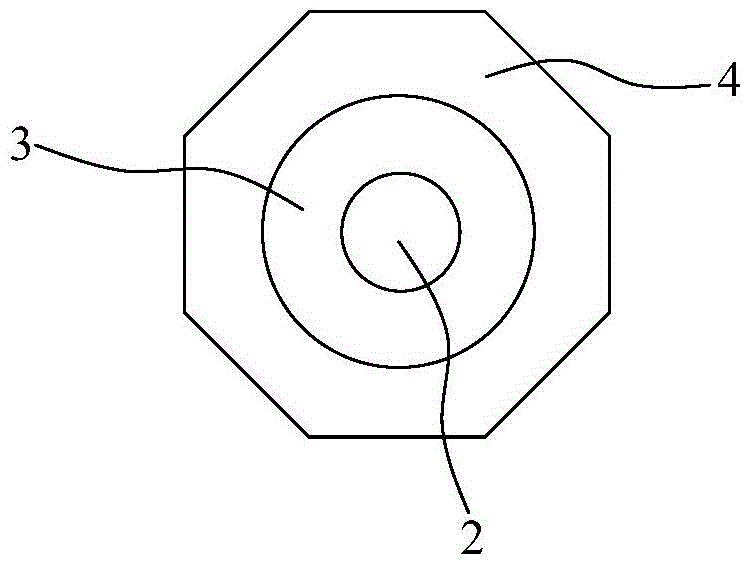

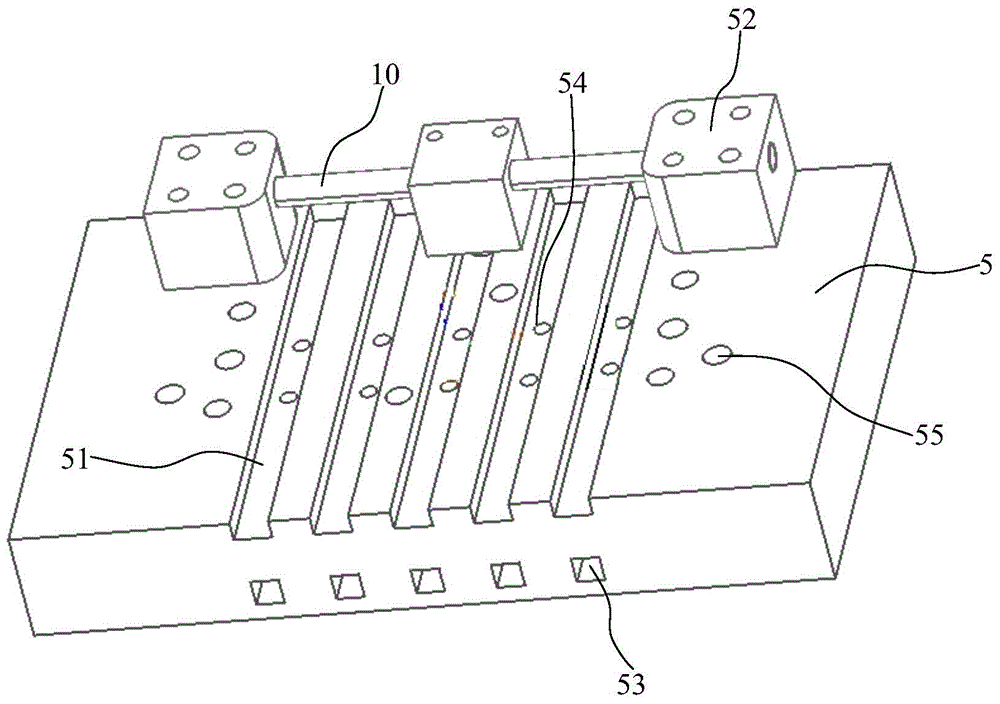

[0024] Embodiment: A precision parts assembly device with size control function, the precision parts include an external screw 2, an internal and external nut 3 mounted on the external thread of the external screw 2, and a hexagonal inner thread installed on the external thread of the internal and external nut 3 Screw sleeve 4, the distance between the outer screw 2 and the end face of the inner and outer nut 3 is the first distance, and the distance between the inner and outer nut 3 and the end face of the hexagonal inner screw sleeve 4 is the second distance; precision parts assembly device It includes a base 5 with several grooves 51, a first rotating cover 6, a second rotating cover 7 and a third rotating cover 8, and one side of the upper surface of the base 5 is provided with three positioning blocks 52. The same side ends of the first rotating cover plate 6, the second rotating cover plate 7 and the third rotating cover plate 8 each have a connecting block 9, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com