Laser marking machine switching valve

A technology of laser coding machine and valve opening and closing, which is used in printing and other directions to achieve the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0013] The invention provides a widening field and a moderately adjustable switch valve for a laser coding machine.

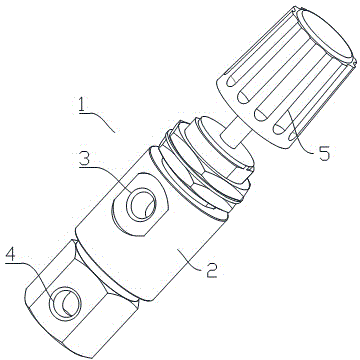

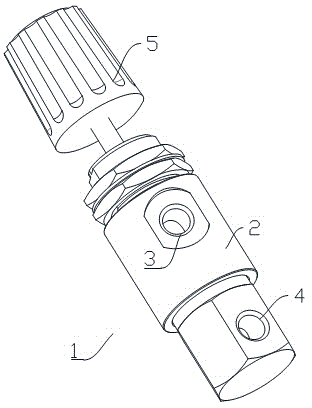

[0014] Such as figure 1 , figure 2 As shown, a switch valve 1 of a laser coding machine includes a conductor 2, a first round hole 3 and a second round hole 4 are opened on the conductor 2, and a Nut knob 5.

[0015] Such as figure 1 , figure 2 As shown, the outer layer of the conductor 2 is covered with a thermal insulator.

[0016] Such as figure 1 , figure 2 As shown, the nut knob 5 has anti-slip threads.

[0017] The laser coding machine of the invention is provided with a conductor on the body, two circular holes a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap