Leakless vessel cover capable of being opened and closed automatically

An automatic opening and closing technology, applied in the field of containers, can solve the problems of increasing product cost, occupying a large space, single opening, etc., to achieve the effect of reducing the use of plastic raw materials, saving product costs, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

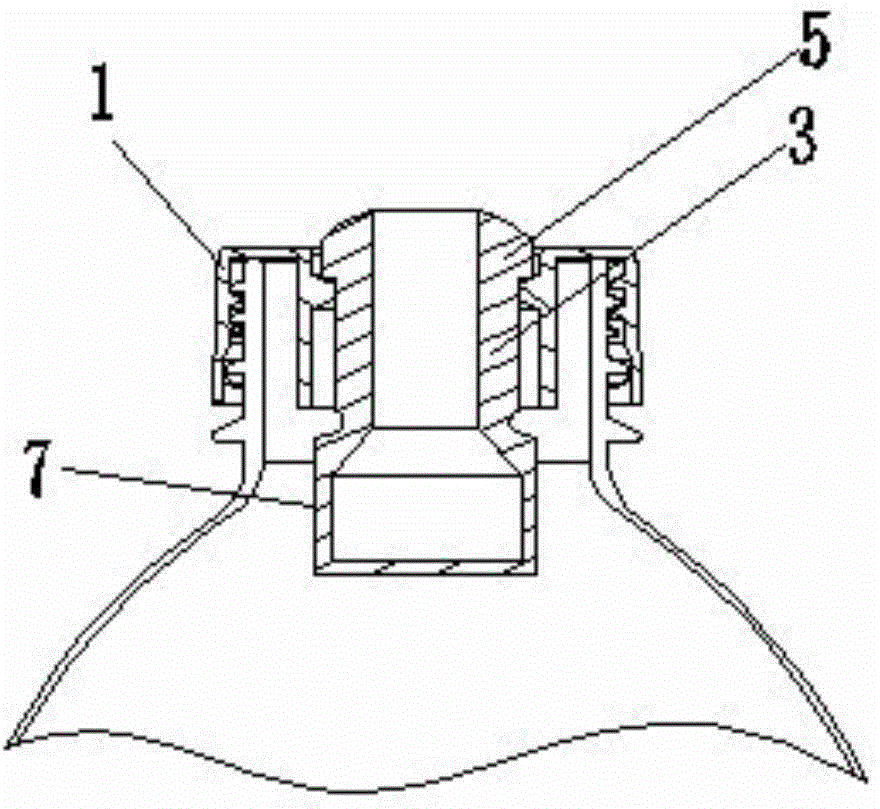

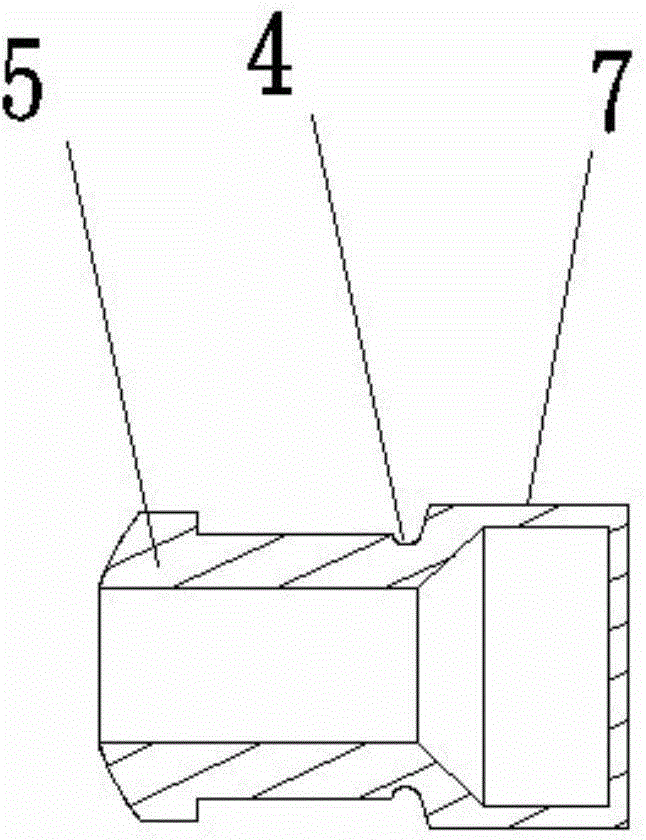

[0026] Embodiment one :Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a non-spout cover that can be opened and closed automatically includes a screw-on container cover 1, and a hole 2 is opened on the top surface of the screw-on container cover 1. The hole 2 is equipped with a device that can automatically discharge water and loosen after being pulled. The lever body 3 that can be automatically closed after the end; the middle part of the lever body 3 is provided with a snap-in groove 4, the upper end of the lever body 3 is provided with a sealing end cover 5 matching the hole, and the lower end of the lever body 3 is provided with an opening for opening. And the water outlet assembly that closes the water outlet of the container. The middle part of the inner side wall of the hole 2 is provided with an annular rib 6 for the clamping groove 4 to abut against. On the side 6, when the trigger body 3 retracts toward the hole 2, the sealing end cover 5 covers ...

Embodiment 2

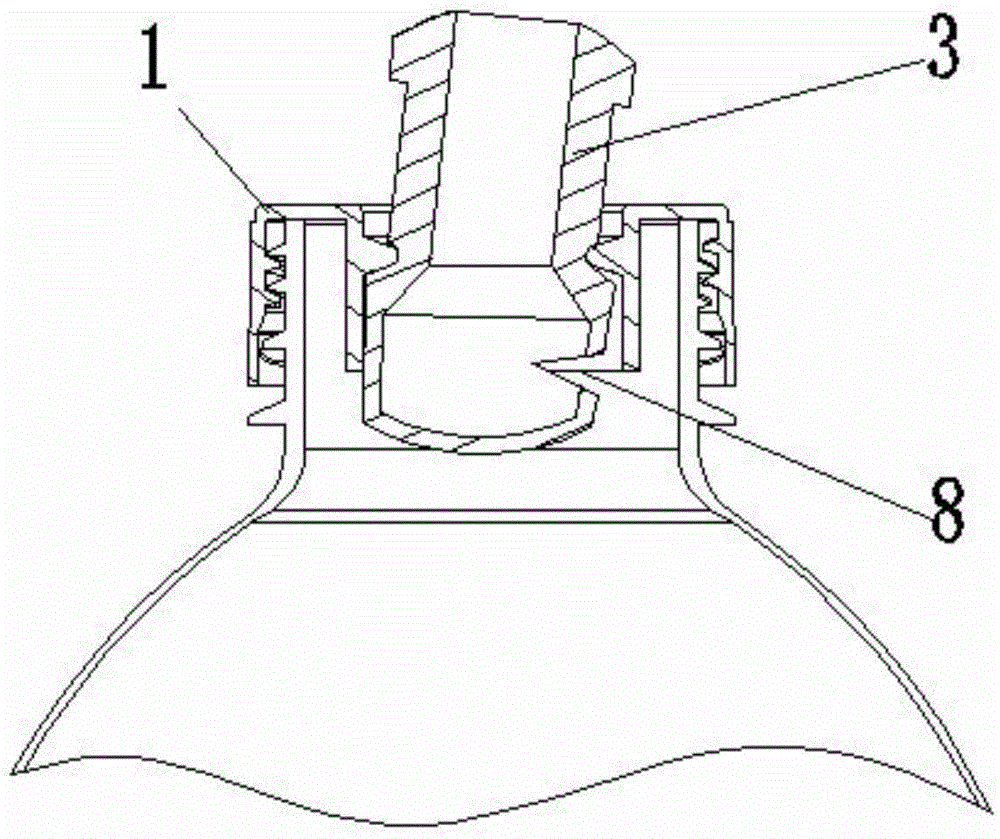

[0029] Embodiment two :Such as Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a non-spout cover that can be opened and closed automatically includes a screw-on container cover 1, and a hole 2 is opened on the top surface of the screw-on container cover 1. The hole 2 is equipped with a device that can automatically discharge water and loosen after being pulled. The lever body 3 that can be automatically closed after the end; the middle part of the lever body 3 is provided with a snap-in groove 4, the upper end of the lever body 3 is provided with a sealing end cover 5 matching with the hole 2, and the lower end of the lever body 3 is provided with a The water outlet assembly for opening and closing the water outlet of the container. The middle part of the inner wall of the hole 2 is provided with an annular rib 6 for the clamping groove 4 to lean against. When the lever body 3 is pulled upward, the bottom surface of the clamping groove 4 is against the ring On t...

Embodiment 3

[0032] Embodiment three :Such as Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, a non-spout cover that can be opened and closed automatically includes a screw-on container cover 1, and a hole 2 is opened on the top surface of the screw-on container cover 1, and the hole 2 is equipped with a device that can automatically discharge water and loosen after being pulled. The lever body 3 that can be automatically closed after the end; the upper end of the lever body 3 is provided with a sealing end cover 5 matching the hole, and the lower end of the lever body 3 is provided with a water outlet assembly for opening and closing the water outlet of the container. The inner side of the hole 2 The middle part of the wall is provided with an annular rib 6 against which the snap-in groove can abut. When the lever body 3 retracts toward the hole 2, the sealing end cap 5 covers the opening of the hole 2 . The water outlet assembly includes a plurality of extrusion shrapne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com