Blowout prevention device and feeding bottle

A blowout preventer and feeding bottle technology, applied in feeding bottles and other directions, can solve problems such as hidden safety hazards, user burns, and poor consumer experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

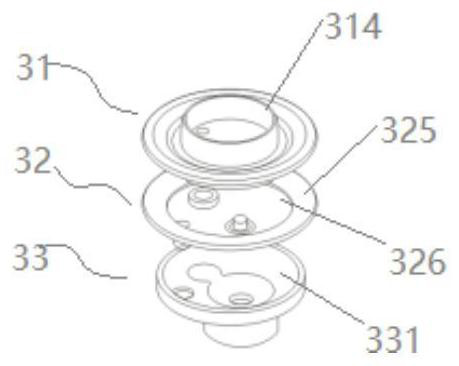

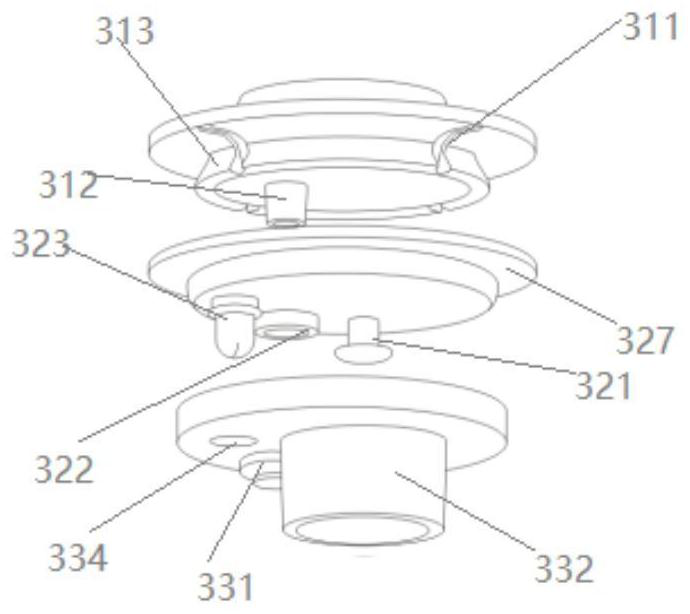

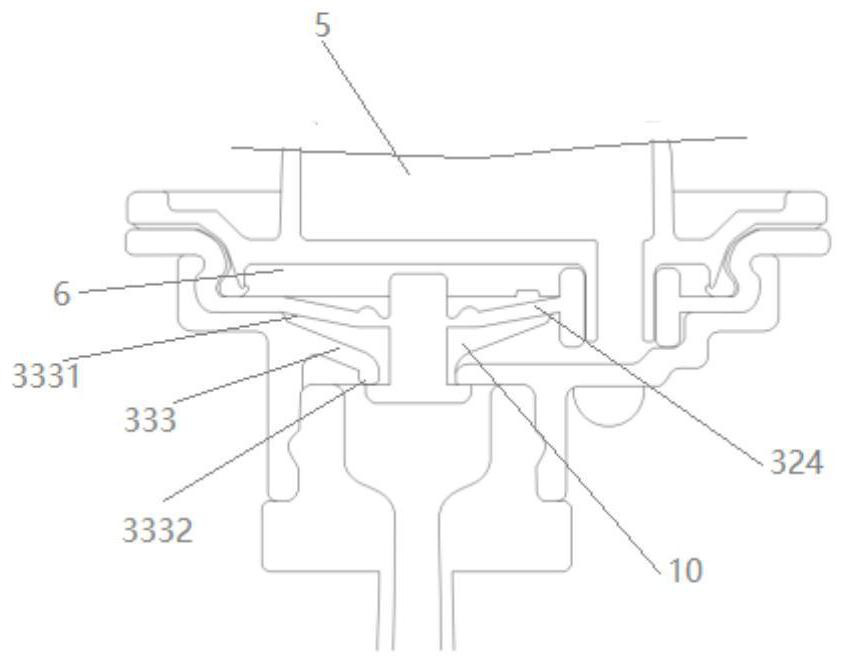

[0033] figure 1 A blowout prevention device provided for the embodiment of the present invention, specifically, such as Figure 2-Figure 4 As shown, the blowout preventer 3 includes an upper cover leaf 31 , a silicone blade 32 and a lower cover leaf 33 . The upper cover leaf 33 includes a first connection portion 313 , an air groove 311 extending to the edge of the upper cover leaf 31 is provided on the outer side wall of the first connection portion 313 , and a first connection is provided in the area of the first connection portion 313 The pipe 312, the first connecting pipe 312 communicates with the first connecting part 313. In this embodiment, the upper cover leaf 31 is further provided with a second connecting portion 314; the first surface 325 of the silicone blade 32 is provided with a groove 326, and the groove 326 and the bottom of the first connecting portion 313 form a first chamber 6, The first chamber 6 communicates with the outside through the air groove 311...

Embodiment 2

[0037] This embodiment provides a milk bottle, including the blowout prevention device in the first embodiment, such as Figure 7 As shown, the feeding bottle includes a bottle body 1 , a nipple 2 and a straw 4 , and the nipple 2 is connected with the bottle body 1 through a blowout preventer 3 . Specifically, when the blowout prevention device 3 is connected with the bottle body 1, the lower cover leaf 33 is inserted inside the bottle body 1, and the edge of the silica gel blade 32 is pressed against the open end of the bottle body 1, which acts as a limit and a For the function of sealing, the connector 7 fixes the blowout preventer 3 on the bottle body 1 . Further, the second connecting portion 314 is inserted into the nipple 2, and forms a cavity 5 with the nipple 2, and the second groove 331 communicates with the cavity 5 through the first connecting pipe 312. In this embodiment, the third The connecting pipe 322 is inserted into the second groove 331 to connect the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com