A kind of phase change energy storage material prepared by microemulsion method and its preparation method

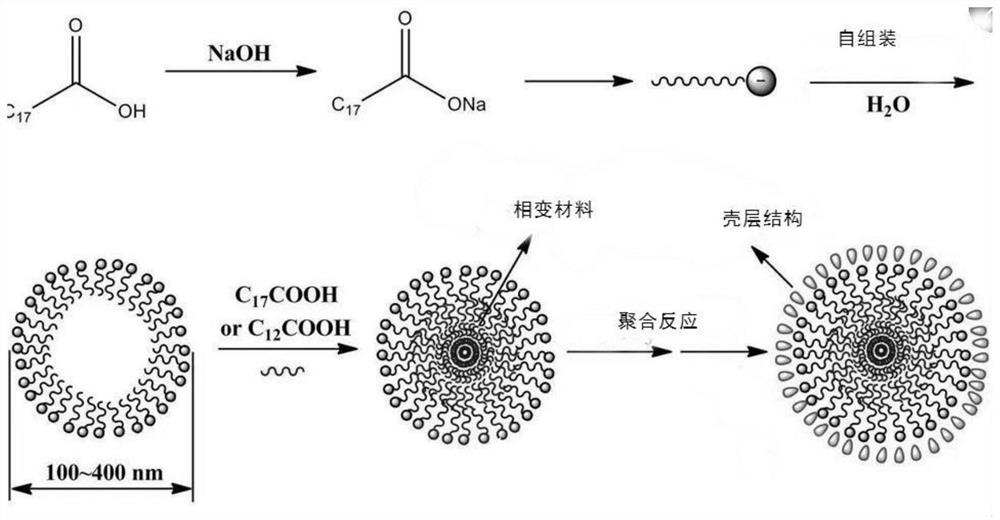

A technology of phase change energy storage material and microemulsion method, which is applied in the field of preparation of phase change energy storage material and its preparation by microemulsion method, which can solve the problems of incomplete coating of energy storage materials, less use of phase change energy storage, capsule Low structural stability and other problems, to achieve the effect of high specific heat capacity, wide application range and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a method for preparing a phase-change energy storage material using the microemulsion method, and the specific steps are:

[0040] (1) Preparation of pre-emulsion:

[0041] 120 parts by weight of distilled water, 5 parts of emulsifier, 5 parts of initiator, and 0.4 part of acid-base regulator were added to the reaction kettle, and after stirring at a high speed for 50 minutes at room temperature, 20 parts of acrylic ester mono Add the liquid mixture and 60 parts of dodecyl alcohol phase change material liquid (if it is solid, heat it to make it melt into liquid) into the reaction kettle, and then stir it at high speed for 30 minutes, then place it in the ultrasonic container for side-by-side After stirring and ultrasonicating for 2 hours, stop stirring and ultrasonicating, take out the material, pour it into an empty bottle for sealed storage, and obtain a pre-emulsion; the high-speed stirring speed is 600rpm;

[0042] (2) Preparation of phase ch...

Embodiment 2

[0050] This embodiment provides a method for preparing a phase-change energy storage material using the microemulsion method, and the specific steps are:

[0051] (1) Preparation of pre-emulsion:

[0052] Add 100 parts by weight of distilled water, 3 parts of emulsifier, 3 parts of initiator, and 0.2 parts of acid-base regulator into the reaction kettle, and after stirring at a high speed for 40 minutes at room temperature, add 10 parts of acrylate Add the mixed liquid of the monomer mixture and 40 parts of the phase change material (if it is solid, heat it to make it melt into a liquid) into the reaction kettle, and then stir it at a high speed for 20 minutes, then place it in the ultrasonic container for stirring After ultrasonication for 1 hour, stop stirring and ultrasonication, take out the material, pour it into an empty bottle for sealed storage, and obtain a pre-emulsion; the high-speed stirring speed is 450 rpm, and the medium-speed stirring speed is 300 rpm;

[0053...

Embodiment 3

[0062] This embodiment provides a method for preparing a phase-change energy storage material using the microemulsion method, and the specific steps are:

[0063] (1) Preparation of pre-emulsion

[0064] Add 110 parts by weight of distilled water, 5 parts of emulsifier, 4 parts of initiator, and 0.4 part of acid-base regulator into the reaction kettle, and after stirring at a high speed for 45 minutes at room temperature, add 20 parts of acrylate Add the mixed liquid of the monomer mixture and 50 parts of the phase change material (if it is solid, heat it to make it melt into a liquid) into the reaction kettle, and then stir it at a high speed for 30 minutes, then place it in the ultrasonic container for stirring After ultrasonication for 1 hour, stop stirring and ultrasonication, take out the material, pour it into an empty bottle for sealed storage, and obtain a pre-emulsion; the high-speed stirring speed is 600rpm;

[0065] (2) Preparation of phase change energy storage ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com