Mobile container and its anti-wave board

A wave-proof board, mobile technology, applied in the direction of containers, large containers, packaging, etc., can solve the problems of large transportation load, heavy wave-proof board, metal wave-proof board is not resistant to specific medium corrosion, etc., to reduce transportation. The effect of reducing load and self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

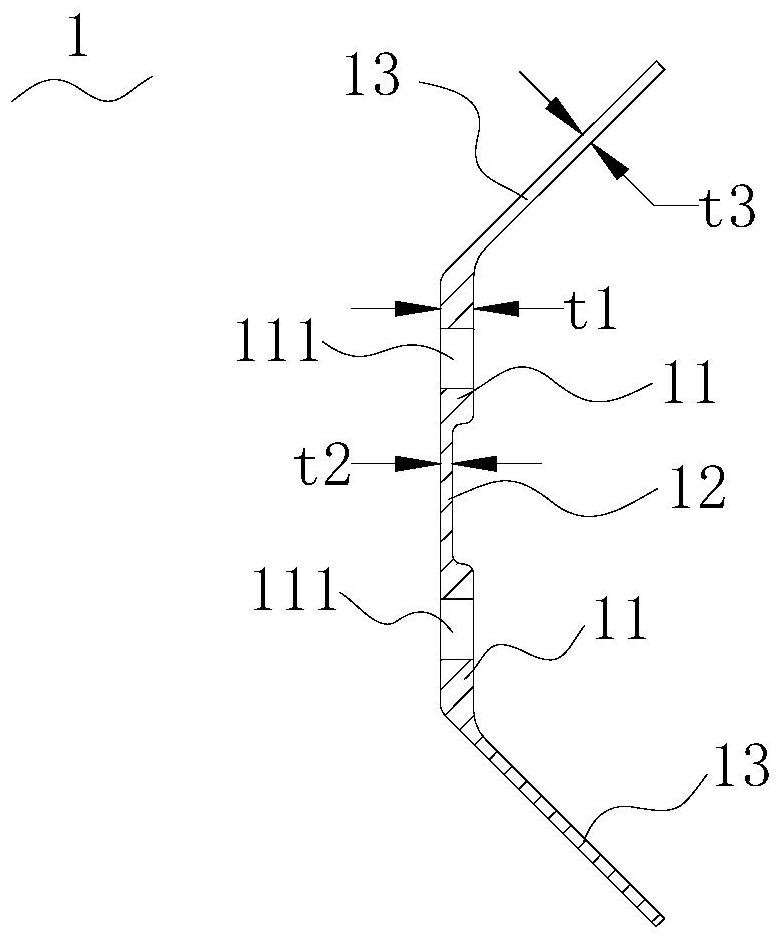

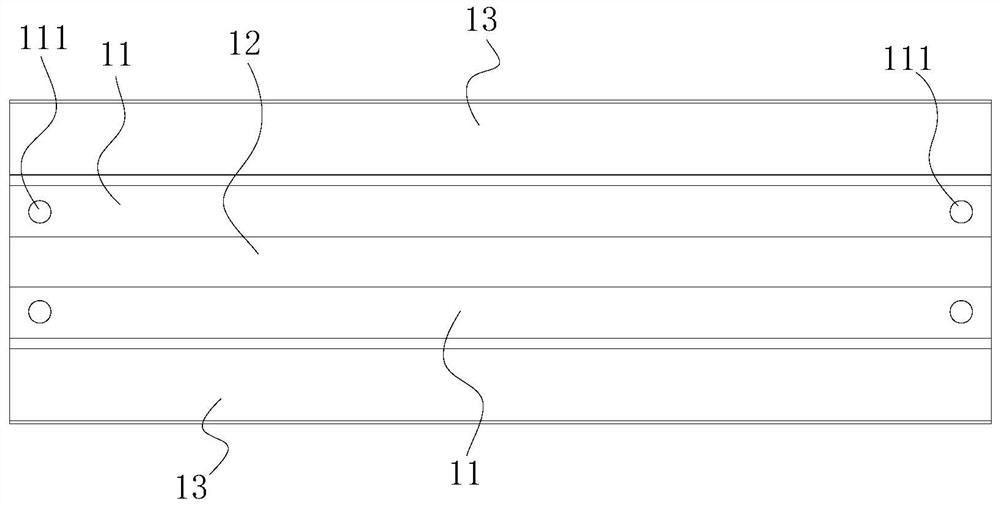

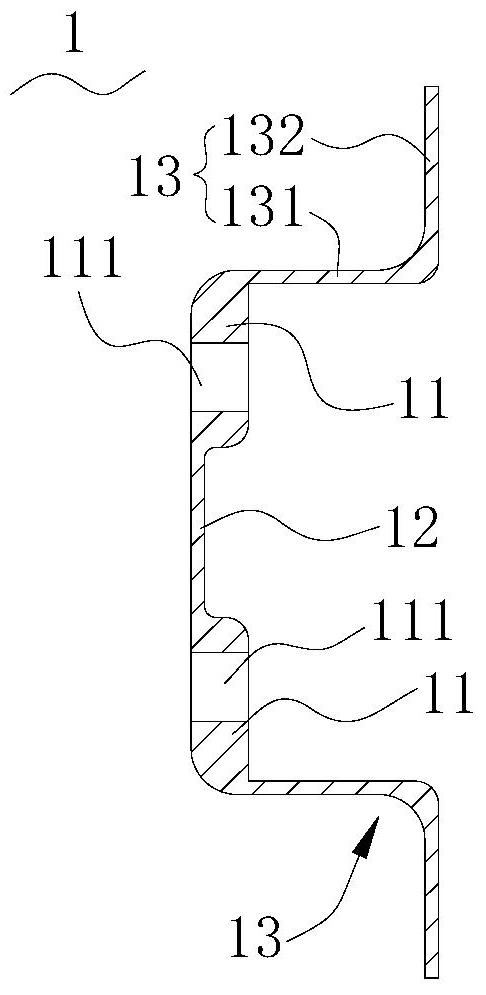

[0046] see figure 1 and figure 2 In this embodiment, the anti-wave board 1 includes a first part 11 , a second part 12 and a third part 13 which are combined and connected according to the width direction. Wherein, the first parts 11 are provided as two separated parts, the second part 12 is connected between the two first parts 11 , and the third parts 13 are also provided as two, which are respectively connected to the outside of the two first parts 11 . The thickness t2 of the second part 12 and the thickness t3 of the third part 13 are both smaller than the thickness t1 of the first part 11 , the thickness t2 of the second part 12 and the thickness t3 of the third part 13 may be the same or different, and they do not matter The specific range of thickness t1, t2 and t3 of each part can be determined according to actual needs.

[0047] The first part 11 , the second part 12 and the third part 13 are all flat plates, because the thickness of the second part 12 and the thi...

no. 4 example

[0058] see Figure 5 , the difference between this embodiment and the third embodiment of the anti-wave board is: in this embodiment, in the three straight line segments 121, 122 and 123 constituting the cross section of the second part 12, the straight line segment 121 and the straight line segment 122 form an obtuse angle. The straight line segment 122 and the straight line segment 123 are also connected at an obtuse angle, and the straight line segments 121 and 123 are respectively connected with a first portion 11 at an obtuse angle.

no. 5 example

[0060] see Image 6 The difference between this embodiment and the third embodiment of the wave-proof board is that: in this embodiment, the cross-section of the second part 12 is wavy, and the two first parts 11 are connected to two ends of the wavy second part 12 respectively.

[0061] The sixth embodiment of the anti-wave board

[0062] see Figure 7 The difference between this embodiment and the third embodiment of the wave-proof board is that: in this embodiment, the cross-section of the second part 12 is arc-shaped, and the two first parts 11 are connected to two ends of the arc-shaped second part 12 respectively.

[0063] Seventh embodiment of anti-wave board

[0064] see Figure 8 , the difference between this embodiment and the third embodiment of the anti-wave board is that: in this embodiment, the anti-wave board 1 includes two separate second parts 12, while the first part 11 is only provided with one, and the two second parts 12 are listed on either side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com