A vibrating trough lifting and moving device

A technology of moving device and vibrating slot, applied in the direction of lifting device, etc., can solve the problems of affecting the running performance of vibration slot, inconvenient removal, deformation of vibration slot balance body, etc., to achieve convenient and fast removal process, ensure appearance integrity, and eliminate vibration slot. The effect of the possibility of balancing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

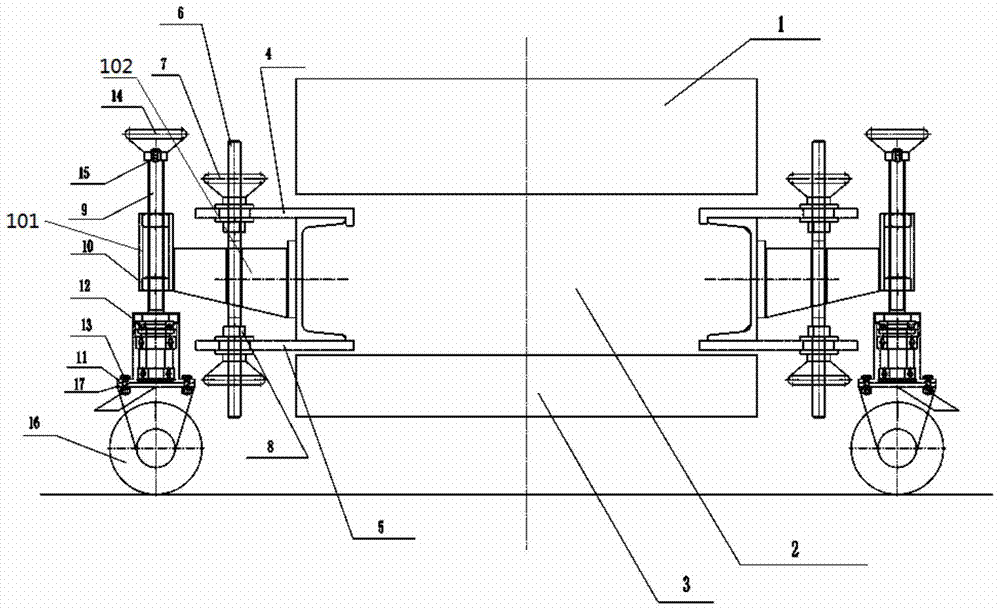

[0011] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

[0012] figure 1 Shown is a structural diagram of the vibrating trough lifting and moving device of the present invention. The vibrating trough lifting and moving device is used to be installed on the left, right, front and rear parts of the vibrating tank, including a locking part, a lifting part, and a roller moving part.

[0013] The locking part includes an upper splint 4, a lower splint 5, a clamping screw 6, a first circular handle 7, and an adjustment nut 8. The clamping screw 6 passes through the upper splint 4 and the lower splint 5 from top to bottom in turn, and the clamping screw The upper end and the lower end of 6 are respectively provided with a first circular handle 7 and an adjusting nut 8 . After the upper splint 4 and the lower splint 5 clamp the frame 2 of the tank body, rotate the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com