A device integrating engine oil sampling and oil temperature measurement

A technology of oil temperature and engine, applied in the direction of lubrication indicator, adding/discharging lubricant, lubricating parts, etc. It can solve the problems of inconvenient adjustment of insertion depth, cumbersome safety problems, and easy oil leakage, etc., so as to facilitate normal use and Assessment, fast and safe operation, and the effect of reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

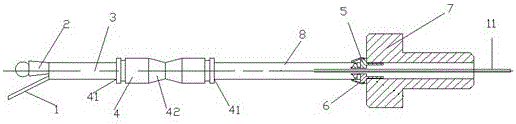

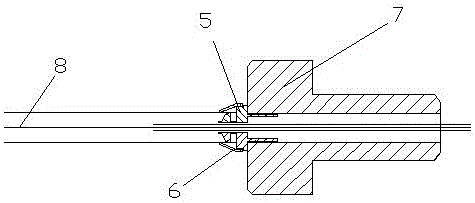

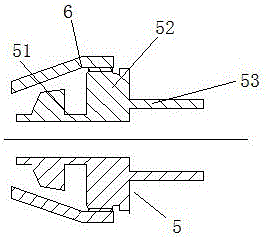

[0015] see Figure 1 to Figure 5 As shown, the device for engine oil sampling and oil temperature measurement for engine testing includes a temperature sensor 1 , an oil drain bolt 7 , a sealing plug 2 , a first Teflon tube 3 and a second Teflon tube 8 . The rear end of the first Teflon tube 3 is connected with the front end of the second Teflon tube 8 through a quick joint 4, and the quick joint 4 includes a joint body 42, a ring gear 43 arranged in the joint body 42 and a ring gear arranged at the joint body 42 two ends. The switch 41 is used to realize the expansion and contraction of the ring gear 43 . The rear end of the second Teflon tube 8 is connected with the oil drain bolt 7 through the pressure sensor seat base 5 and the cap 6. The rear end of the pressure sensor seat base 5 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com