Wire scrap filtering device

The technology of a filter device and a lint filter, which is applied in the field of washing machines, can solve problems such as inability to solve the problem of lint backflow, and achieve the effects of simple opening, improved collection effect, and easy installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A kind of lint filtering device of the present invention is described in detail below in conjunction with accompanying drawing:

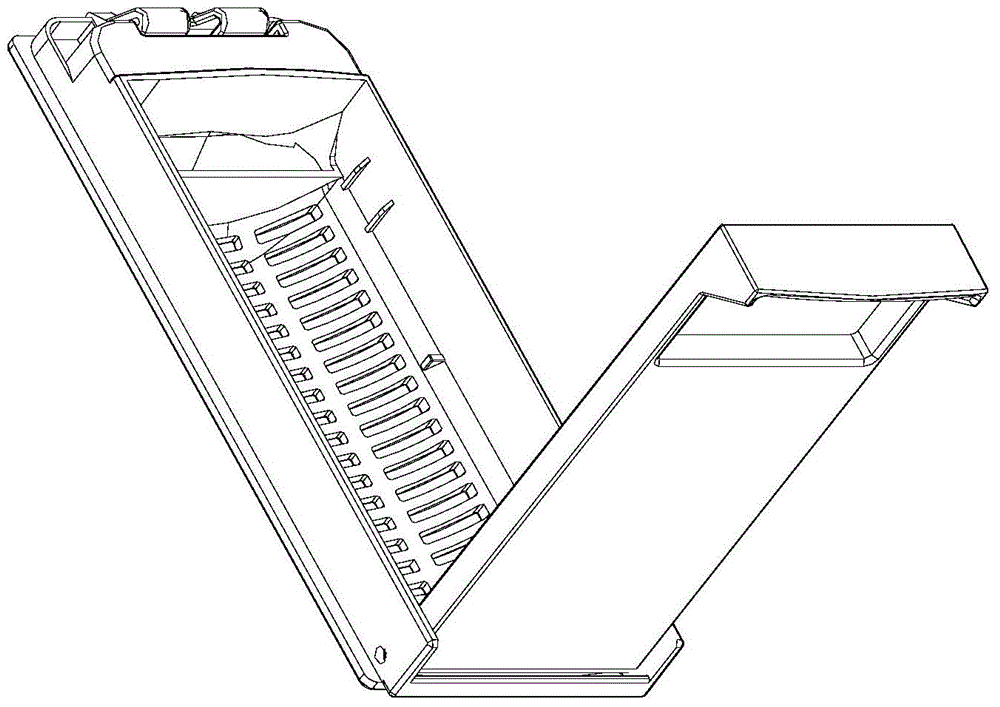

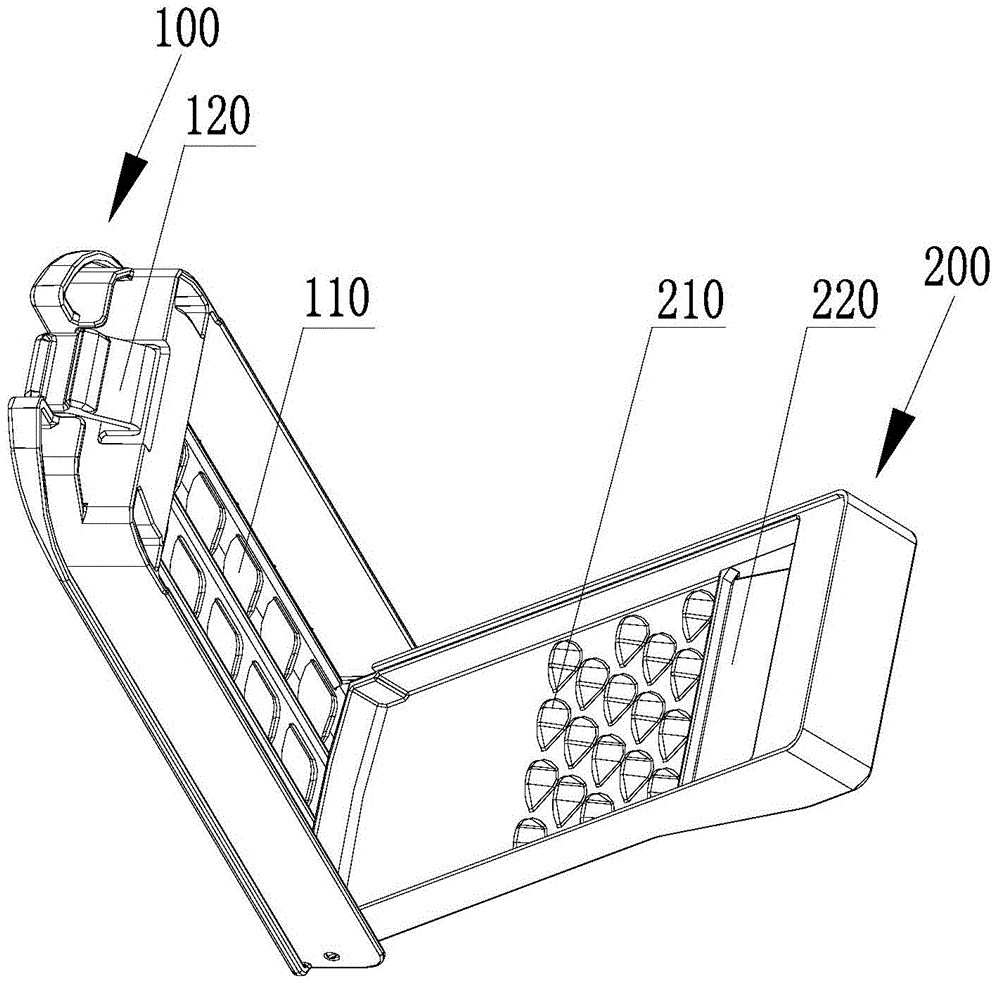

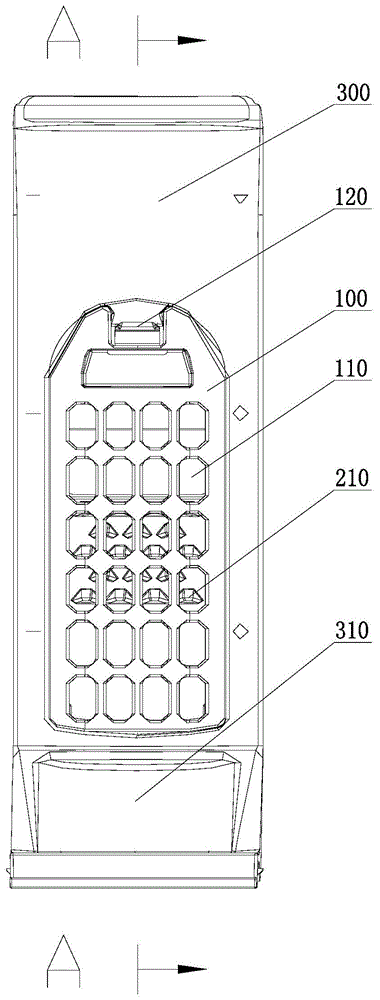

[0032] A kind of lint filtering device provided by the present invention comprises a lint filter, such as figure 1 As shown, the lint filter includes a filter front cover 100 and a filter rear cover 200 connected thereto. When installed on a washing machine, the filter front cover 100 and the filter rear cover 200 should be combined. The filter front cover 100 When combined with the filter back cover 200, a closed filter cavity is formed between the two; when it is necessary to clean the lint collected in the lint filter cavity, the lint filter is taken out, and the filter is opened The front cover 100 and the filter rear cover 200 are cleaned. The filter front cover 100 is provided with a filter part 110 for washing water to pass and filter, the filter rear cover 200 is provided with a water inlet 220, and the inner wall of the filter rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com