A Series Shock Absorber Based on Leaf Springs

A technology of leaf springs and shock absorbers, which is applied in the field of tandem shock absorbers, can solve the problems of large size of the shock absorber system, small radial bearing capacity, and large height space, etc., and achieves expanded application range, easy assembly, and simplified design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

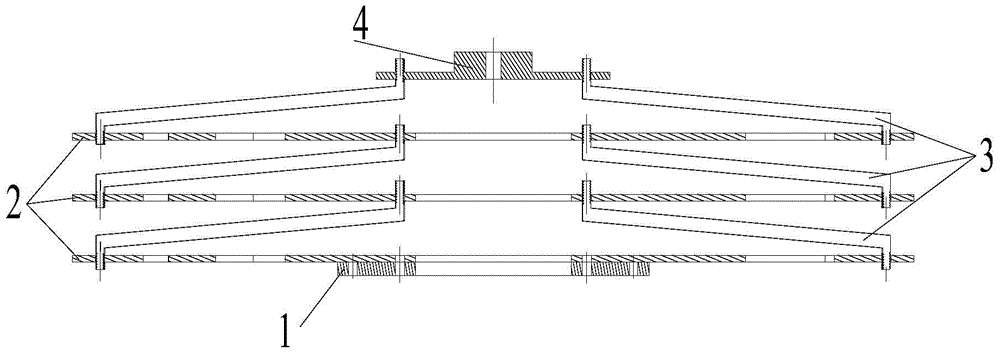

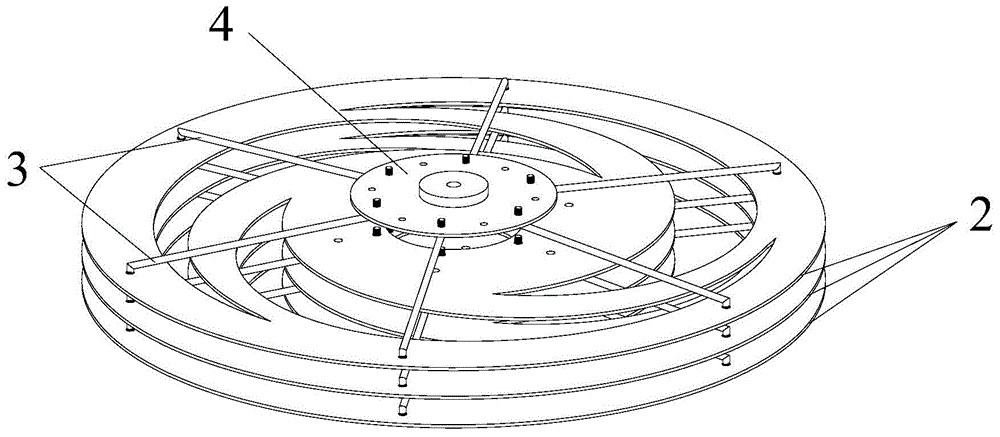

[0030] like figure 1 , 2 As shown, a tandem shock absorber based on leaf springs includes a bottom mounting part 1, a plurality of leaf springs 2, a plurality of elastic rods 3 and a top mounting part 4; a leaf spring 2 is fixed on the bottom mounting part 1, Each leaf spring 2 is stacked, and every two leaf springs 2 are supported by a plurality of elastic rods 3 , and the topmost leaf spring 2 is supported and connected to the top mounting part 4 by a plurality of elastic rods 3 .

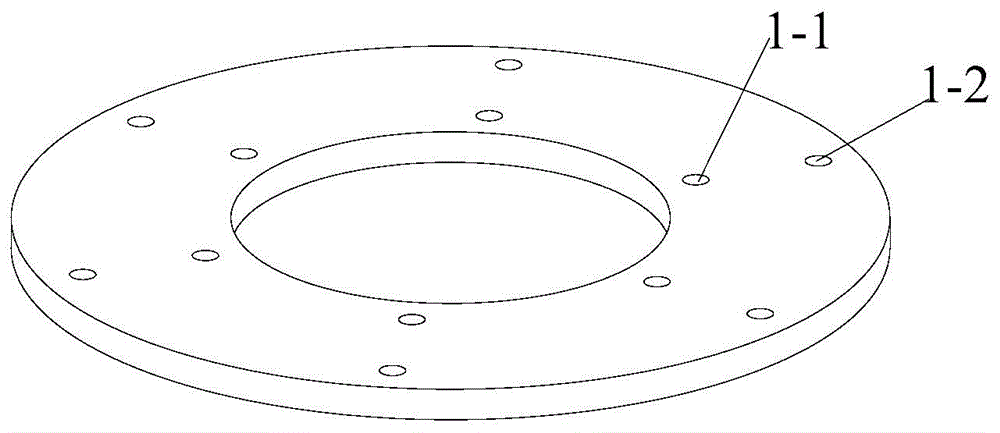

[0031] like image 3 As shown, the bottom mounting part 1 is a sheet-shaped ring structure, the difference between the inner diameter of the sheet-like ring structure and the outer diameter of the ring is a predetermined value, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com