A laser energy meter probe

A laser energy meter, laser technology, applied in optical radiation measurement, measuring device, photometry and other directions, can solve the problems of thick absorber thickness, low accuracy, low heat transfer coefficient, etc., to reduce temperature loss, Improved accuracy, thermal equilibration time and reduced temperature losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

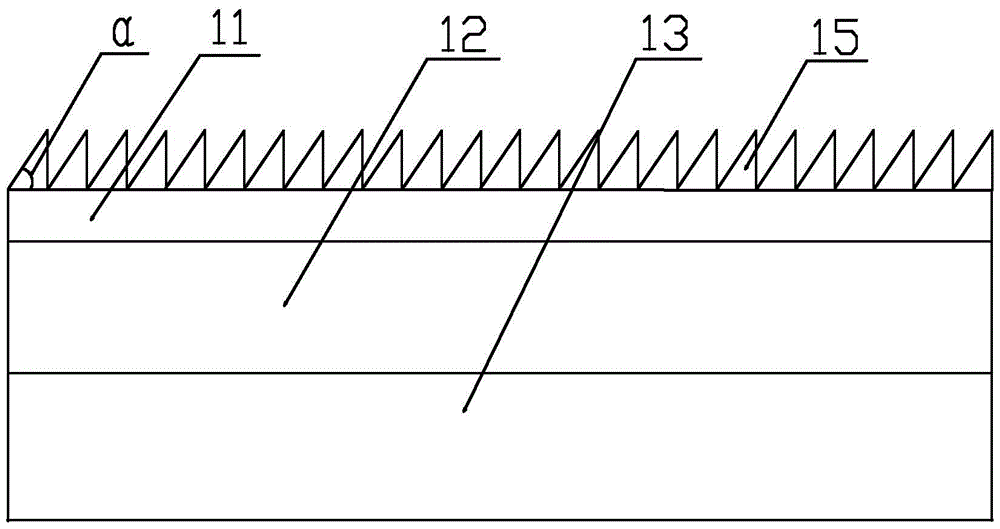

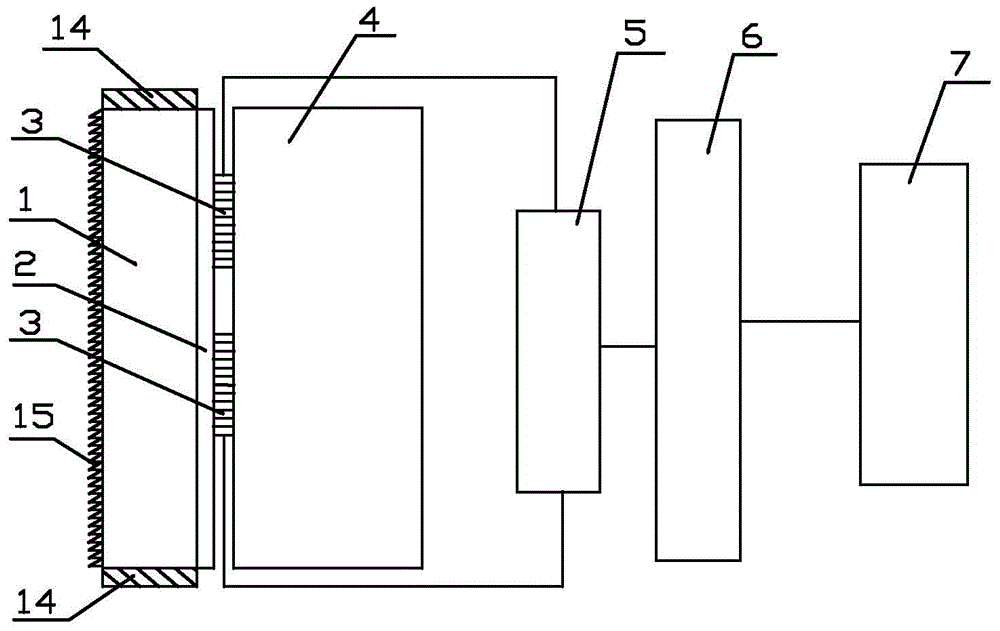

[0029] Such as figure 1 As shown, a laser energy meter probe includes an absorber 1, and the absorber 1 includes a first absorbing sheet 11, a second absorbing sheet 12 and a third absorbing sheet 13. According to the direction of laser transmission, the first absorbing sheet 11 1. The second absorbing sheet 12 and the third absorbing sheet 13 are arranged in sequence, and the first absorbing sheet 11, the second absorbing sheet 12 and the third absorbing sheet 13 are connected as a whole by a hot bond, and the surface of the hot bond is The largest surface of the first absorbent sheet 11, the second absorbent sheet 12 or the third absorbent sheet 13, the absorption coefficient of the first absorbent sheet 11

Embodiment 2

[0035] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

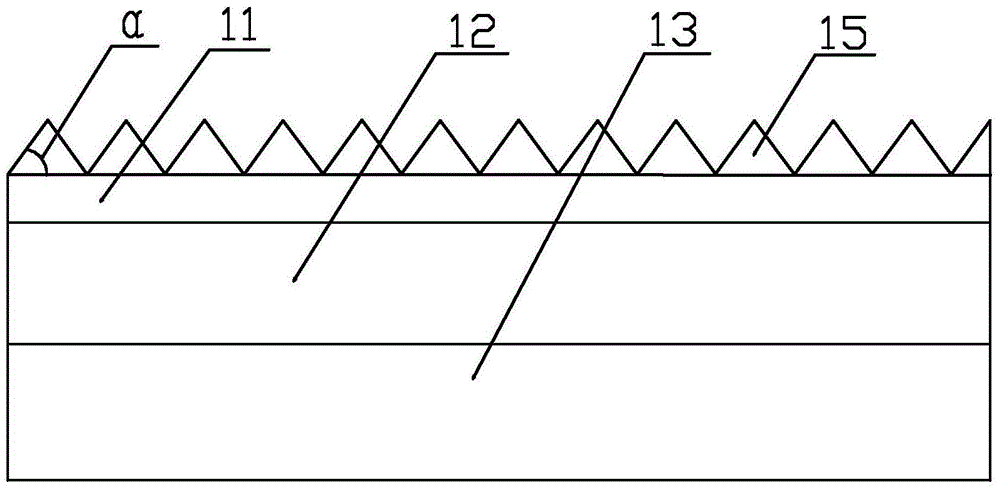

[0036] Such as image 3 As shown, the cross section of the tooth-shaped structure 15 is an isosceles triangle and a right triangle, the absorption coefficient of the first absorbent sheet 11 is 166 / m, the absorption coefficient of the second absorbent sheet 12 is 298 / m, and the third absorbent sheet 12 has an absorption coefficient of 298 / m. The absorption coefficient of the absorbent sheet 13 was 1466 / m.

Embodiment 3

[0038] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0039] The cross section of the tooth-shaped structure 15 is an isosceles triangle, the absorption coefficient of the first absorbent sheet 11 is 241 / m, the absorption coefficient of the second absorbent sheet 12 is 399 / m, and the absorption coefficient of the third absorbent sheet 13 It is 1497 / m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com