Three-dimensional digital particle image generation device and three-dimensional digital particle image generation method based on excitation suction

An image generation device, three-dimensional digital technology, applied in the direction of measuring device, particle and sedimentation analysis, particle size analysis, etc., can solve the problems of difficult application, high cost, affecting surface data collection, synthesis, processing, and analysis, and achieve stability, Uniform effect, clear size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

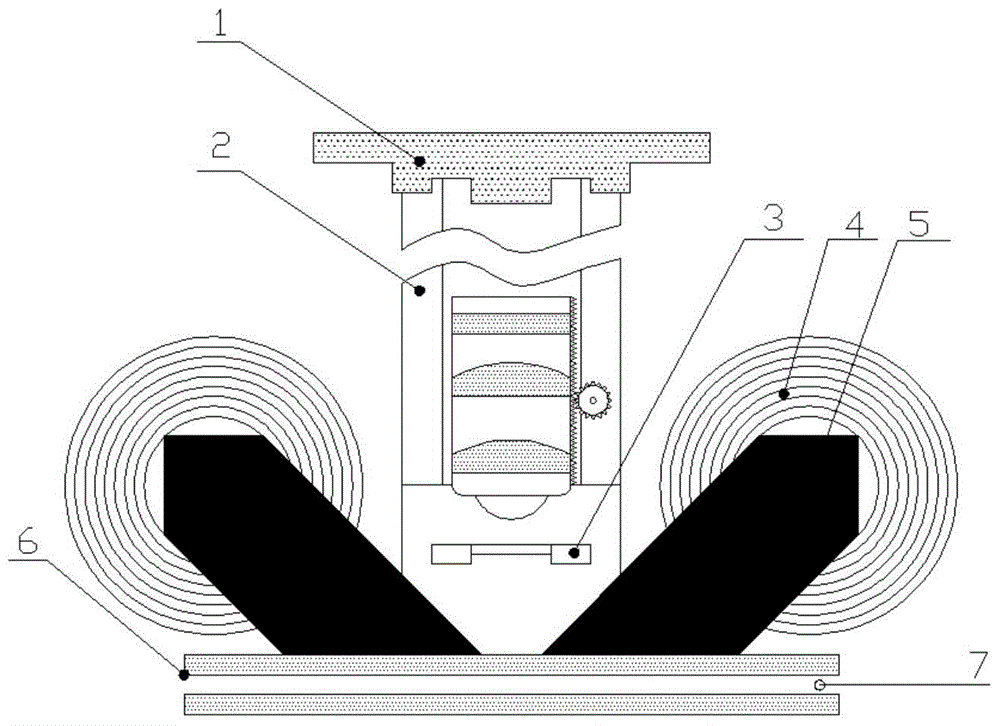

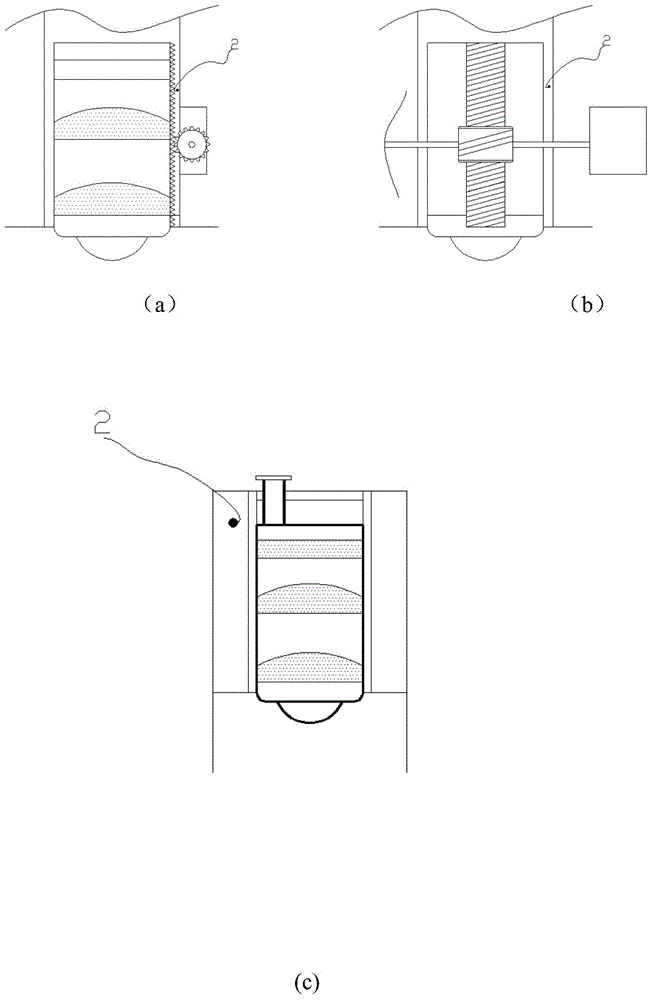

[0032] figure 1 An embodiment of the present invention is illustrated, including an imaging module, an adsorption module, a picture processing module and a light-transmitting sheet 6, and the picture processing module is connected with the imaging module. The imaging module includes an imaging device 1, an optical filter, a lens group, a focusing mechanism 2 and a reflective light source 3. The imaging device 1, the optical filter and the lens group are connected in sequence, the optical filter is arranged above the lens group, and the imaging device 1 is located at Above the filter, the focusing mechanism 2 is arranged on the lens group, and the reflective light source 3 is located below the lens group. The lens group includes one or more lenses to magnify the particle image, and the filter to filter the color. The adsorption module includes an iron core frame, an adsorption component 5 and an inductance coil 4 wound on the iron core frame.

[0033] The imaging module and t...

Embodiment 2

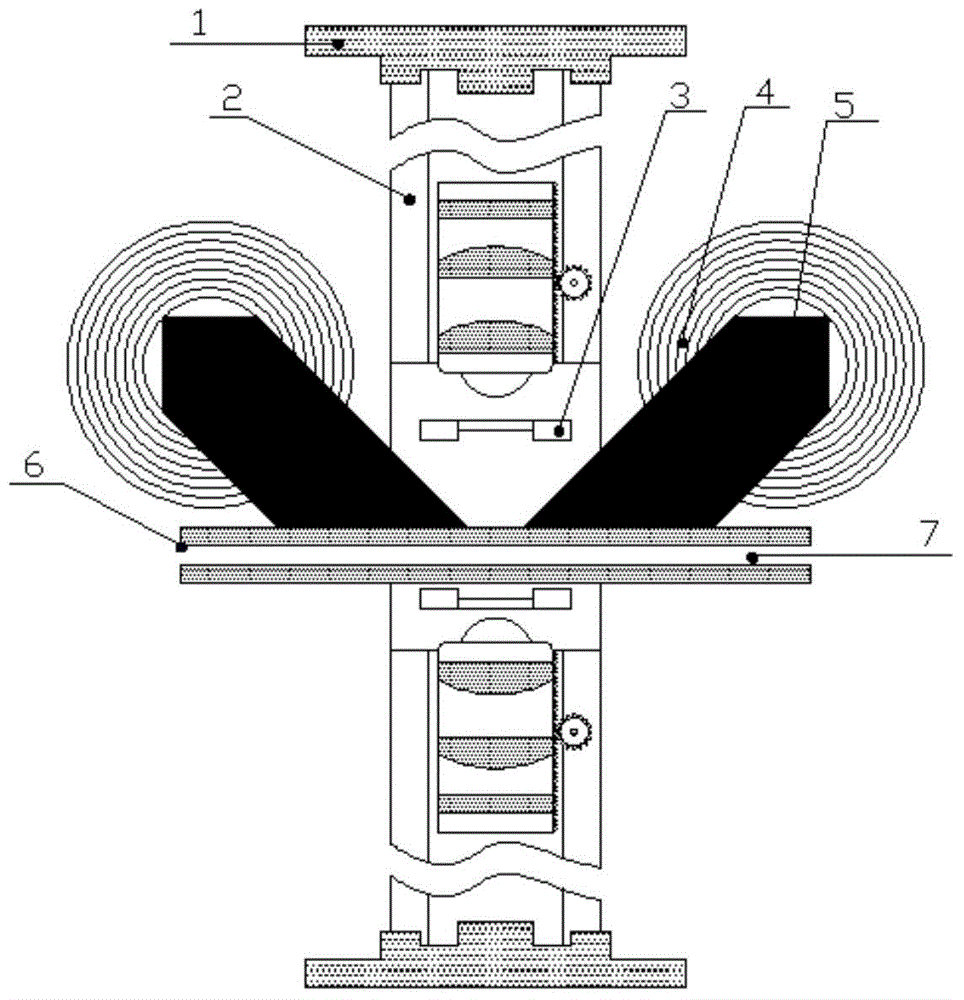

[0047] attached figure 2 Another embodiment of the present invention is illustrated, with the accompanying figure 1 Compared with the illustrated embodiment, a group of imaging modules and light-transmitting sheets are mainly added. The added group of imaging modules and light-transmitting sheets is the same as the group of imaging modules and light-transmitting sheets in Embodiment 1, with the flow channel 7 as the axis of symmetry, symmetrical up and down; the imaging module is the same as the embodiment, and also includes imaging devices 1. Focusing mechanism 2, lens group, reflected light source 3 and optical filter.

[0048] In this embodiment, the focusing mechanism 2 located above and below the flow channel 7 can be adjusted simultaneously. The central position between the two groups of adsorption components 5 is on the same optical path as the center of the reflective light source 3, the focusing mechanism 2, and the imaging device 1; the center of the optical path ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com