Display substrate, manufacturing method of display substrate and display device

A technology for display substrates and display devices, which can be used in static indicators, light guides, optics, etc., and can solve the problems of large loss of brightness and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

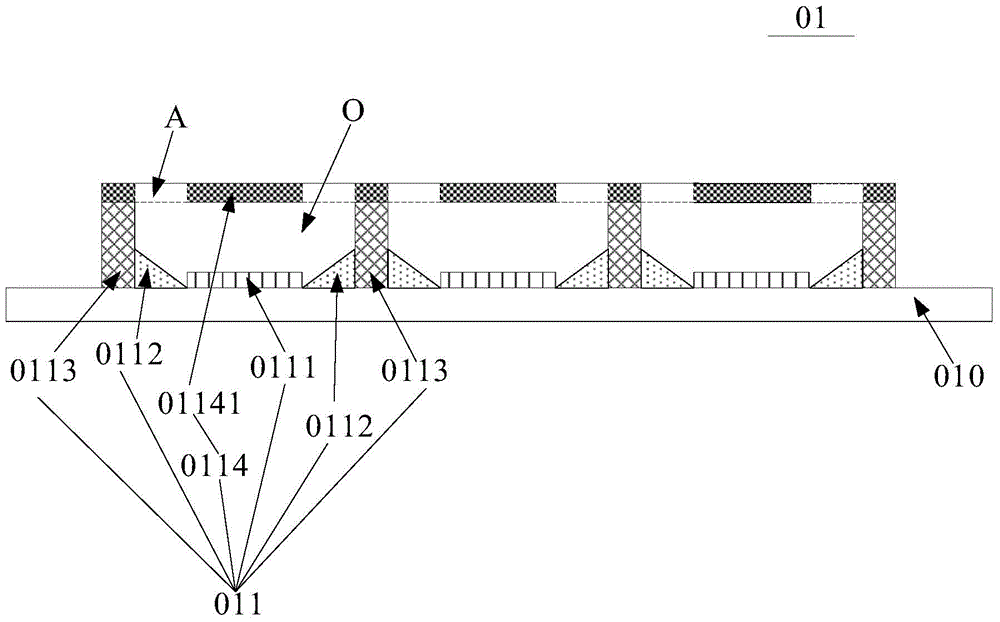

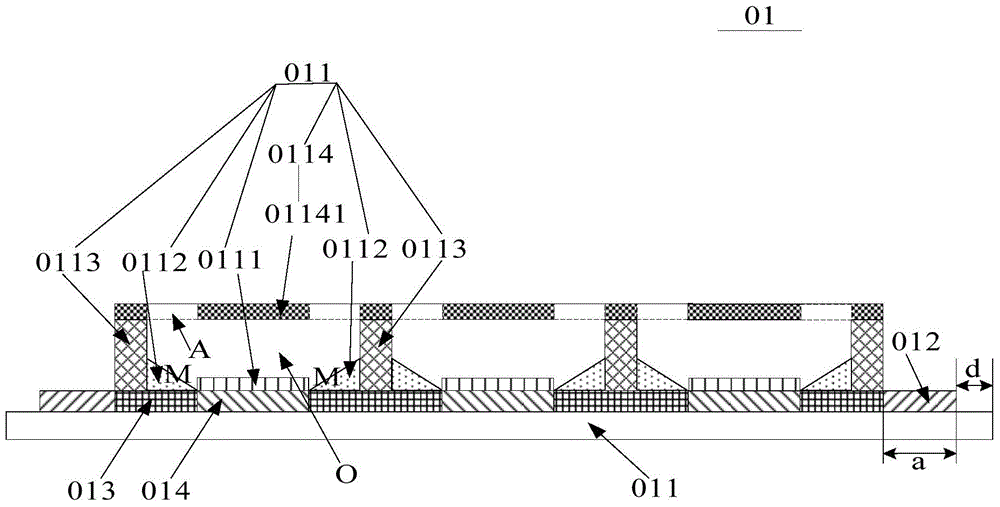

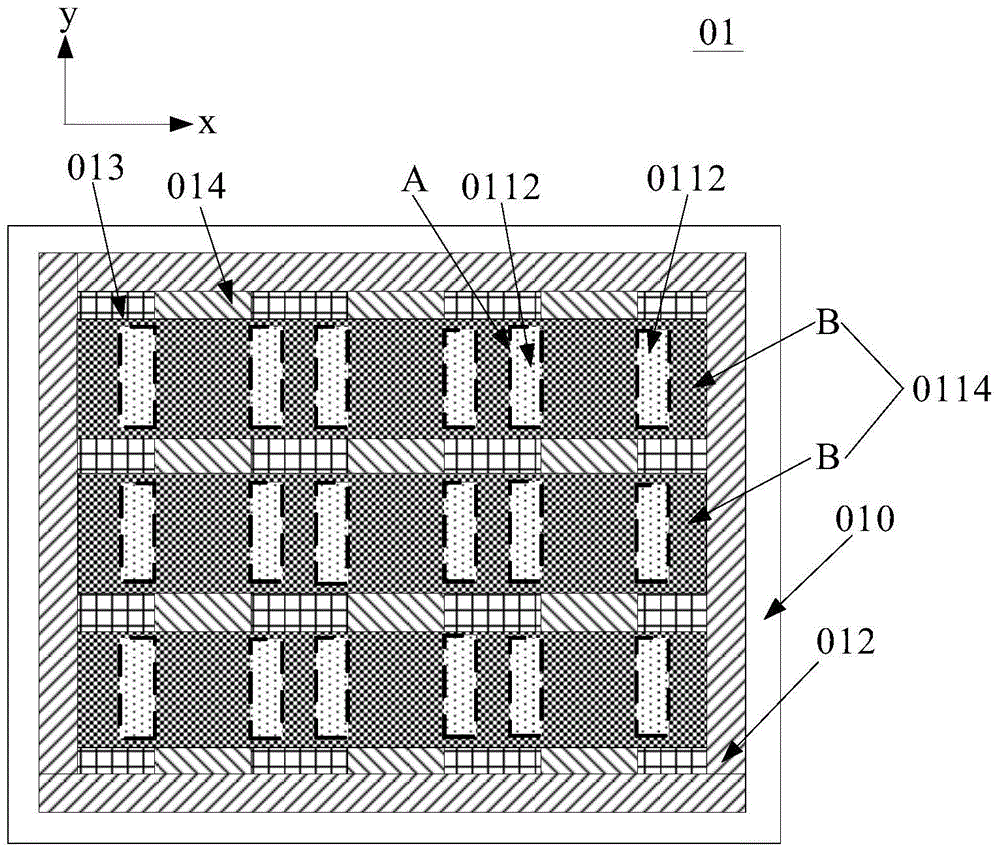

[0116] Please refer to figure 1 , which shows a schematic structural diagram of a display substrate 01 provided by an embodiment of the present invention. see figure 1 , the display substrate 01 includes: a base substrate 010, the base substrate 010 may be a transparent substrate, specifically, it may be a substrate made of light-guiding and non-metallic materials with certain firmness such as glass, quartz, and transparent resin.

[0117] At least one pixel unit 011 is formed on the display area of the base substrate 010 .

[0118] Such as figure 1 As shown, each pixel unit 011 includes: a color-developing structure 0111, a first light-reflecting structure 0112 disposed around the color-developing structure 0111, disposed on at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com