Centrifugal minitype express item sorting and inputting equipment

An input device and centrifugal technology, applied in the field of centrifugal small express input sorting equipment, can solve the problems of inconvenience for small sorting centers, violent sorting accidents by manual sorting, and high labor intensity of staff, so as to avoid The effect of violent sorting accidents, saving sorting time and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

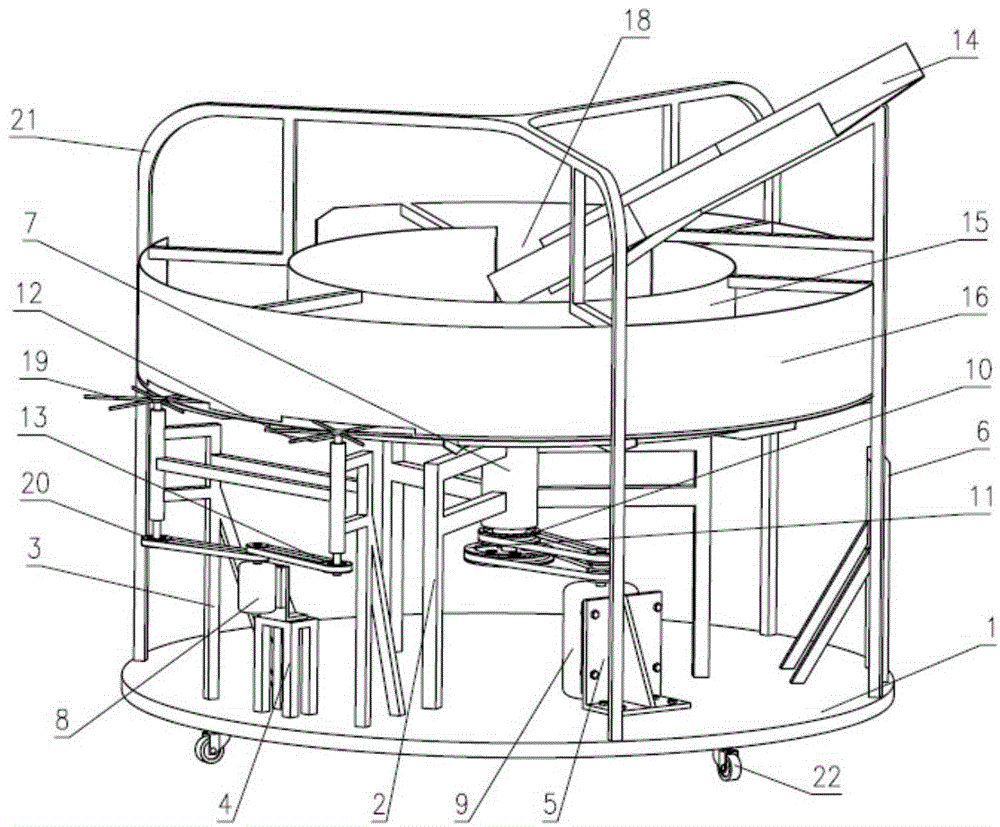

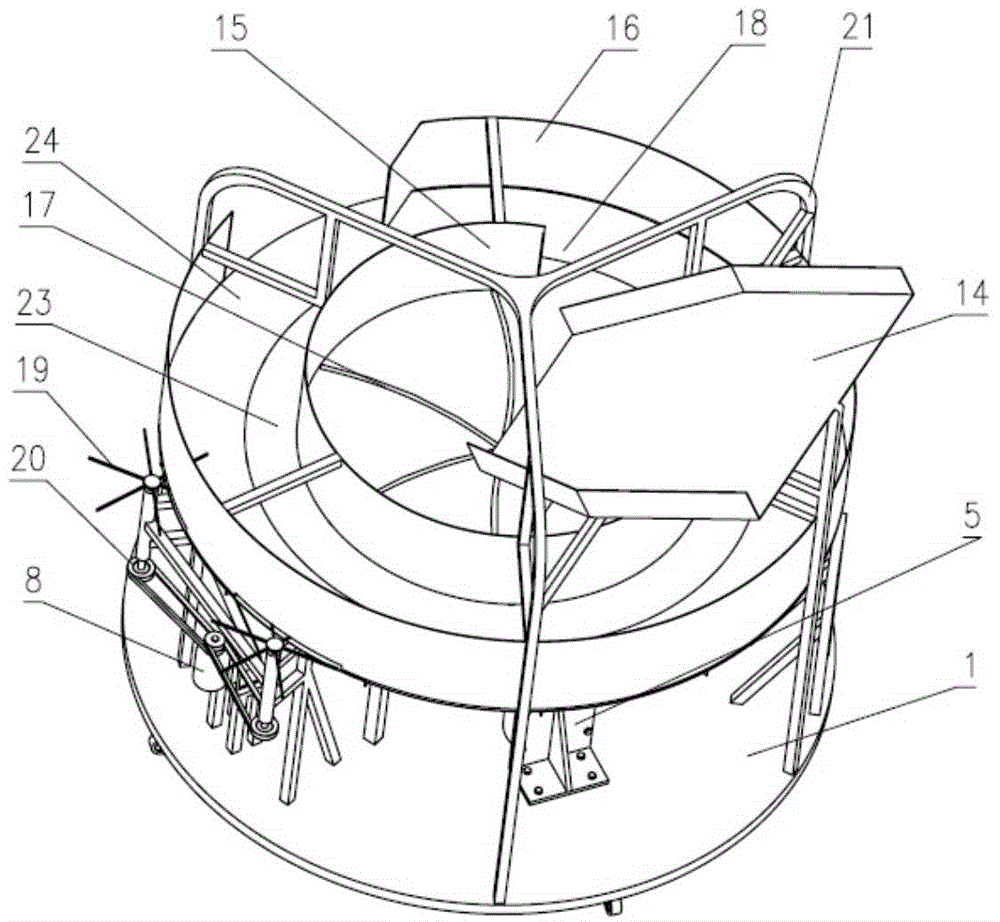

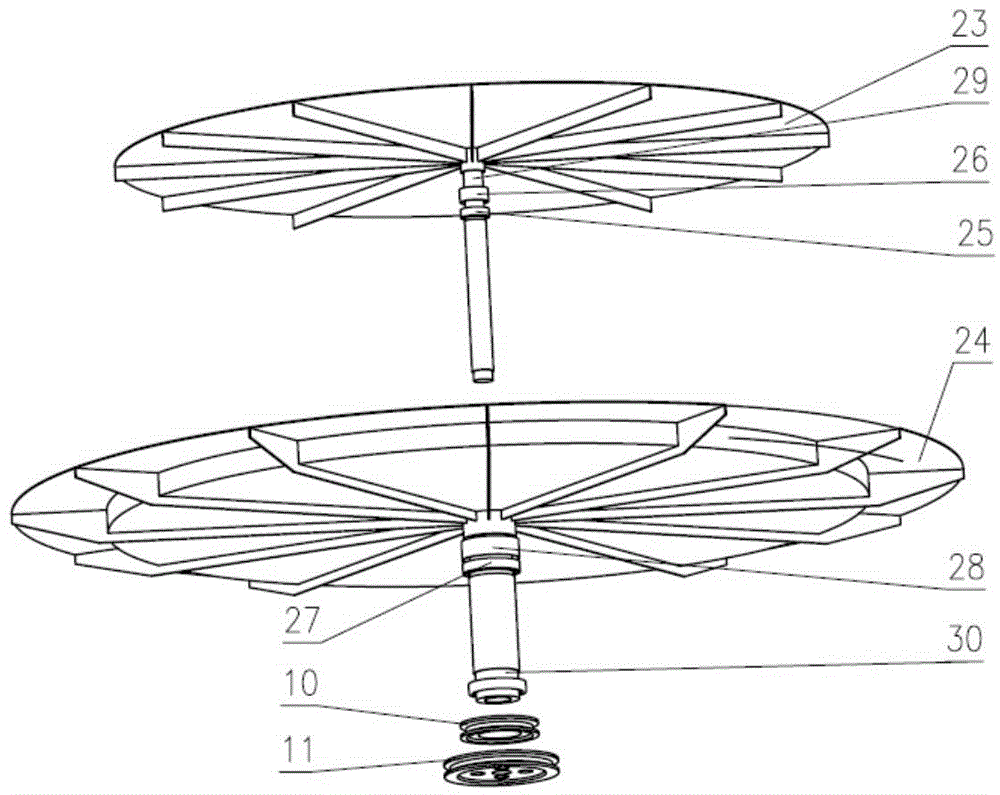

[0025] The schematic diagram of the centrifugal small-scale express sorting input device of the present invention is as follows: Figure 1-Figure 5 As shown, it includes a base 1, a bracket 21, an input slide 14, a first sorting mechanism, a second sorting mechanism, a sorting drive motor 9 and a sorting support mechanism. The bracket 21 is fixedly connected with the base 1 . In this embodiment, the sorting drive motor 9 is fixed on the base 1 through the motor bracket 5 . The first sorting mechanism includes a first turntable 23, a first baffle plate 15, a first rotating shaft 29, and a first transmission mechanism. The first transmission mechanism in this embodiment is a belt transmission mechanism, including a first pulley 11 And the first belt and the second pulley matched with it. The second sorting mechanism includes a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com