Optical fiber tapered grinder and grinding method thereof

A polisher and optical fiber technology, which is used in grinding devices, grinding machine tools, work carriers, etc., can solve the problems of inability to meet the needs of on-site grinding of optical fibers and complex structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with accompanying drawing:

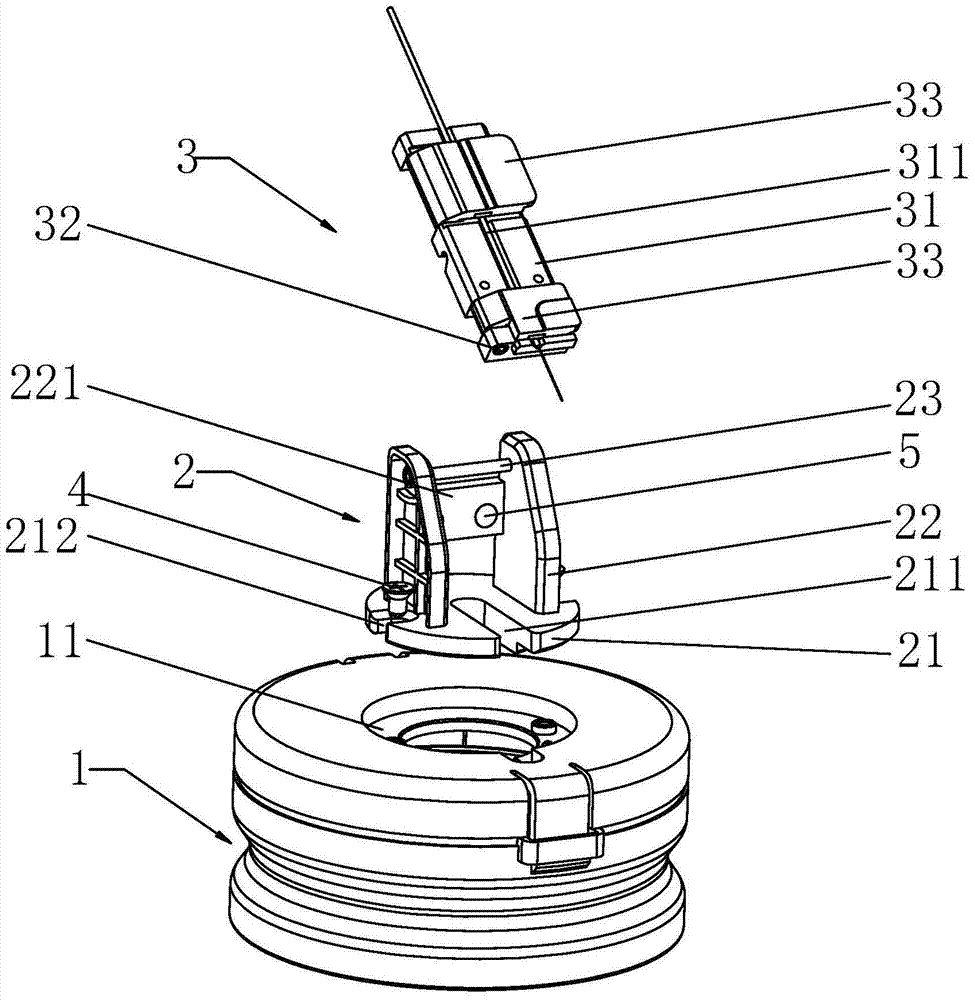

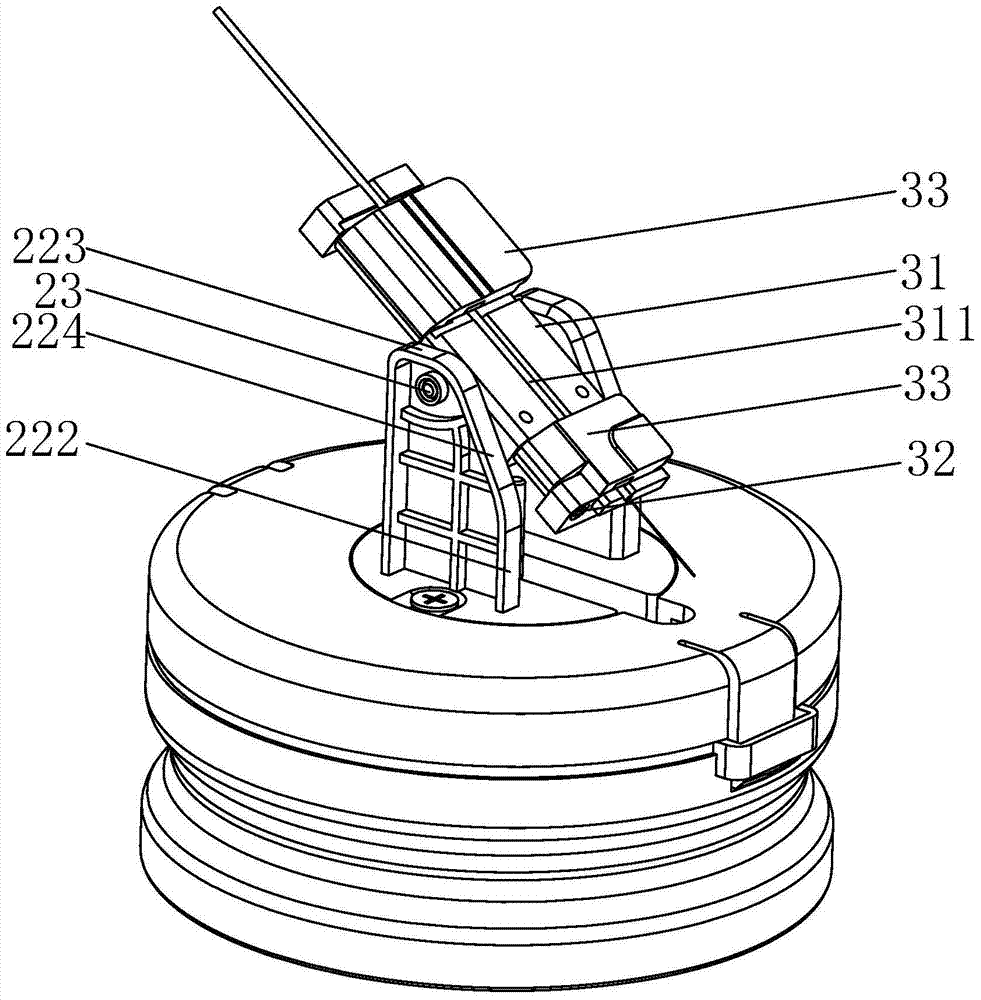

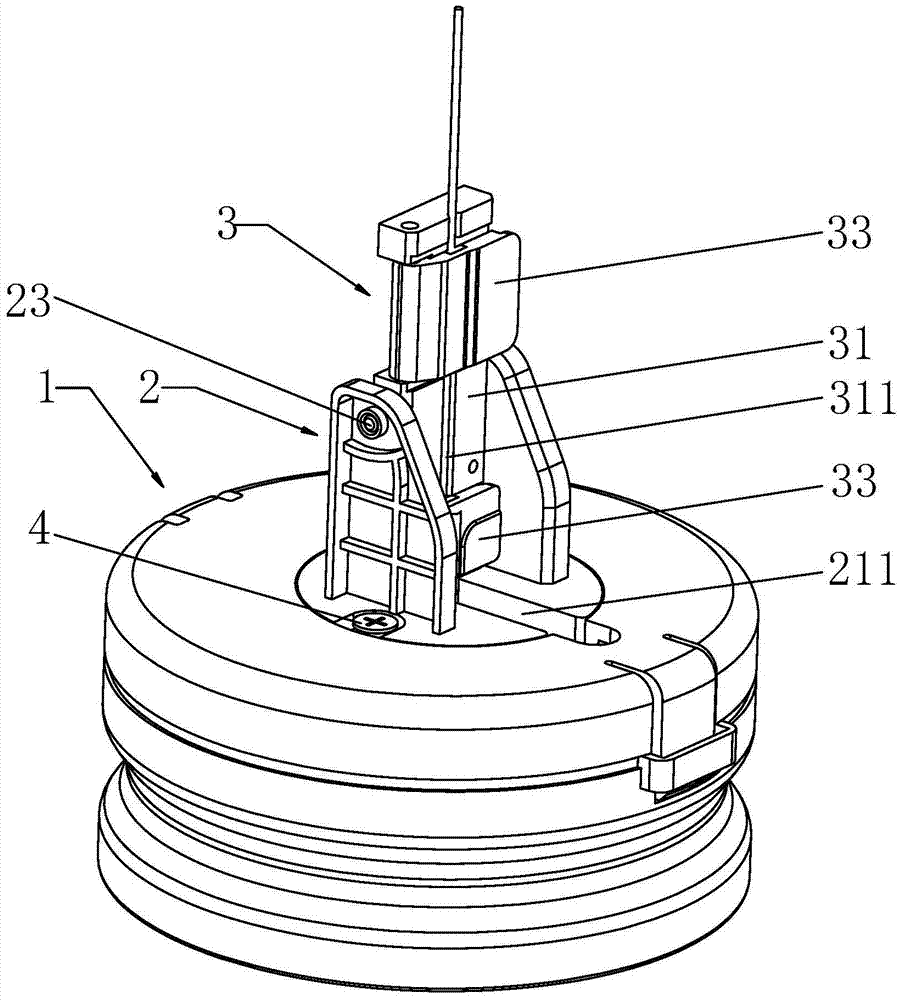

[0048] Figure 1 to Figure 3 , Figure 7 to Figure 13 A first embodiment of the invention is shown.

[0049] see figure 1 As shown, the optical fiber tapered grinder includes a grinder body 1, a base 2 and an optical fiber holder 3, the receiving port 11 on the top of the grinder body 3 is connected to the base 2 via a screw 4, and the pivot 23 on the top of the base 2 is detachable The fiber holder 3 is pivotally connected to the ground. The base 2 and the optical fiber holder 3 are connected to each other through joint members.

[0050] see Figure 1 to Figure 3 As shown, the base 2 is composed of the disc seat 21, the open groove 211 that runs through the edge of the disc seat 21 to the center of the circle, the screw holes 212 that are respectively recessed on the edge of the disc seat 21 perpendicular to the open groove 211, and the screw holes 212 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com