Conveying device for conveying bricks

A technology for conveying devices and bricks, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., and can solve the problems of large volume and difficult steering of conveying devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

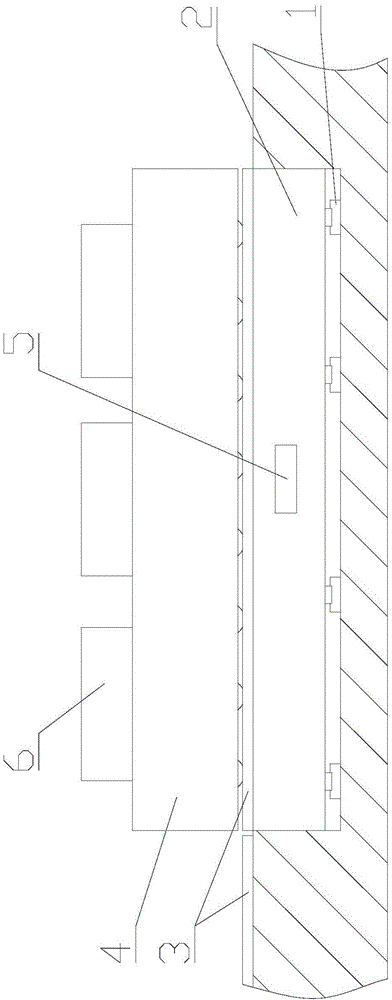

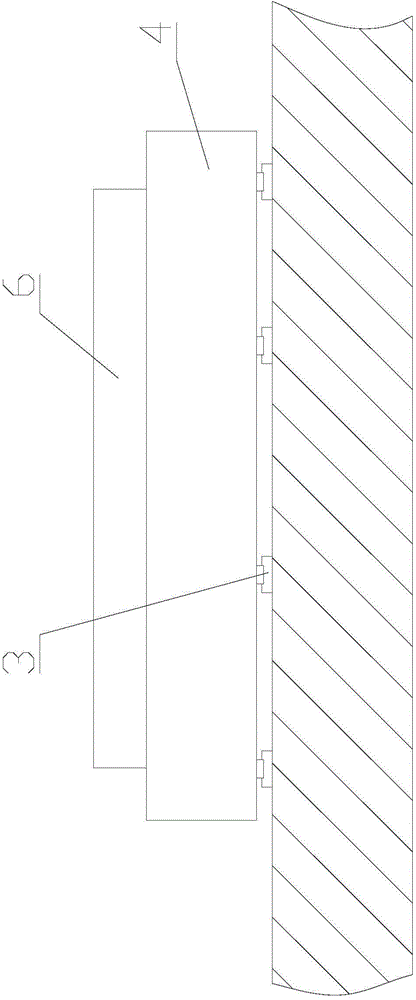

[0013] Such as figure 1 and figure 2 As shown, the conveying device for conveying bricks includes a first track 1, a first moving seat 2, a second track 3 and a second moving seat 4, the first moving seat 2 is slidably connected on the first track 1, and the second Two rails 3 are installed on the upper surface of the first mobile seat 2, and the second mobile seat 4 is slidably connected on the second rail 3, and the extension direction of the second rail 3 is perpendicular to the extension direction of the first rail 1, and the second rail 3 There are four, four second rails 3 are arranged at equal intervals, of course the second rails 3 can also be provided with two or three or five or more, the front and rear of the first mobile seat 2 are respectively provided with handles 5. A brick seat 6 is built on the upper surface of the second mobile seat 4 . The above-mentioned first track 1 is usually installed on the ground, and the second track 3 is also installed on the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com