Stepped shaft type part conveying mechanism

A conveying mechanism and stepped shaft technology, which is applied in the field of stepped shaft-type parts conveying mechanism, can solve the problems such as the inability of the pump head to move or tilt, and achieve the effects of improved conveying efficiency, strong controllability, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

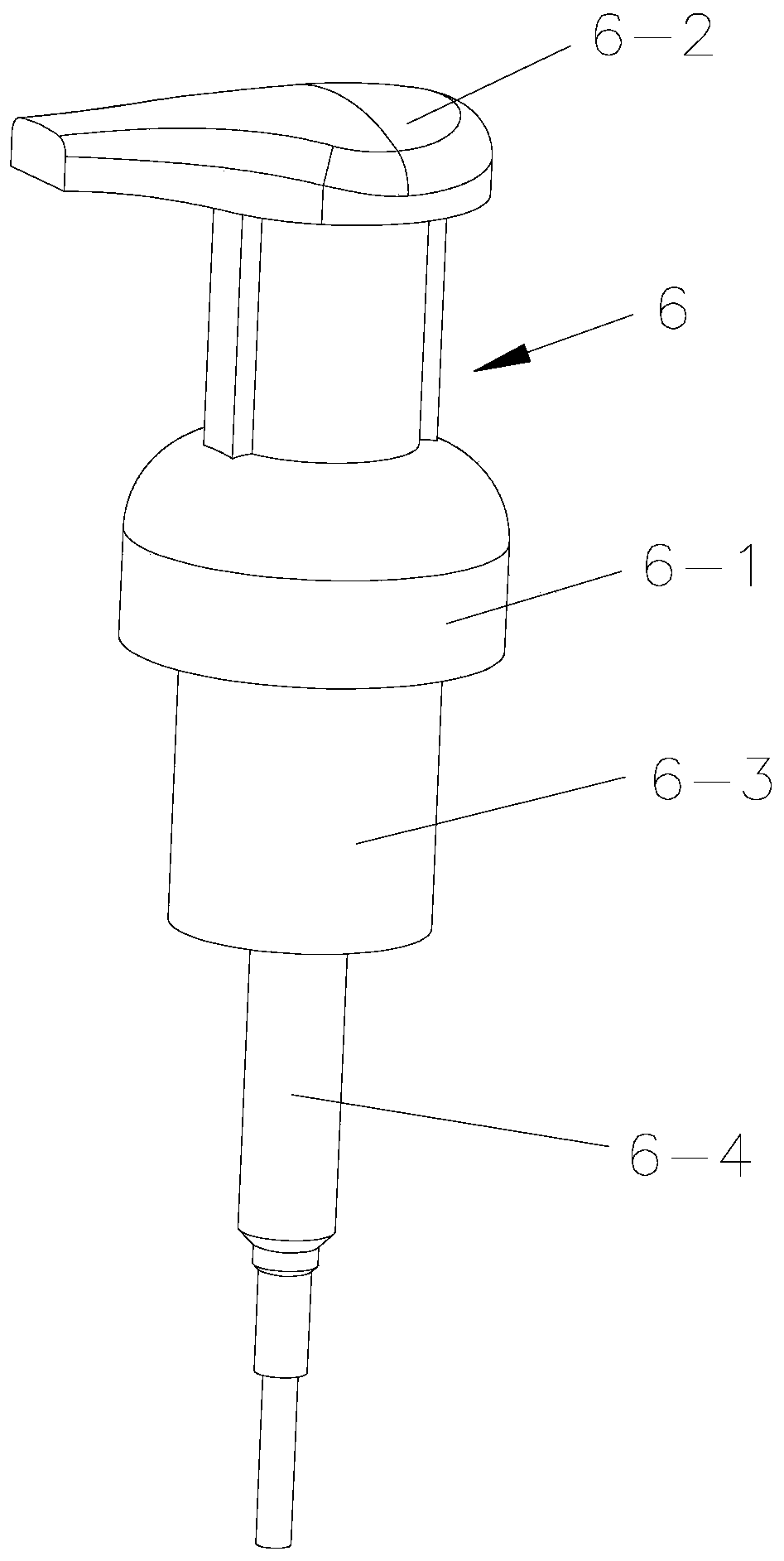

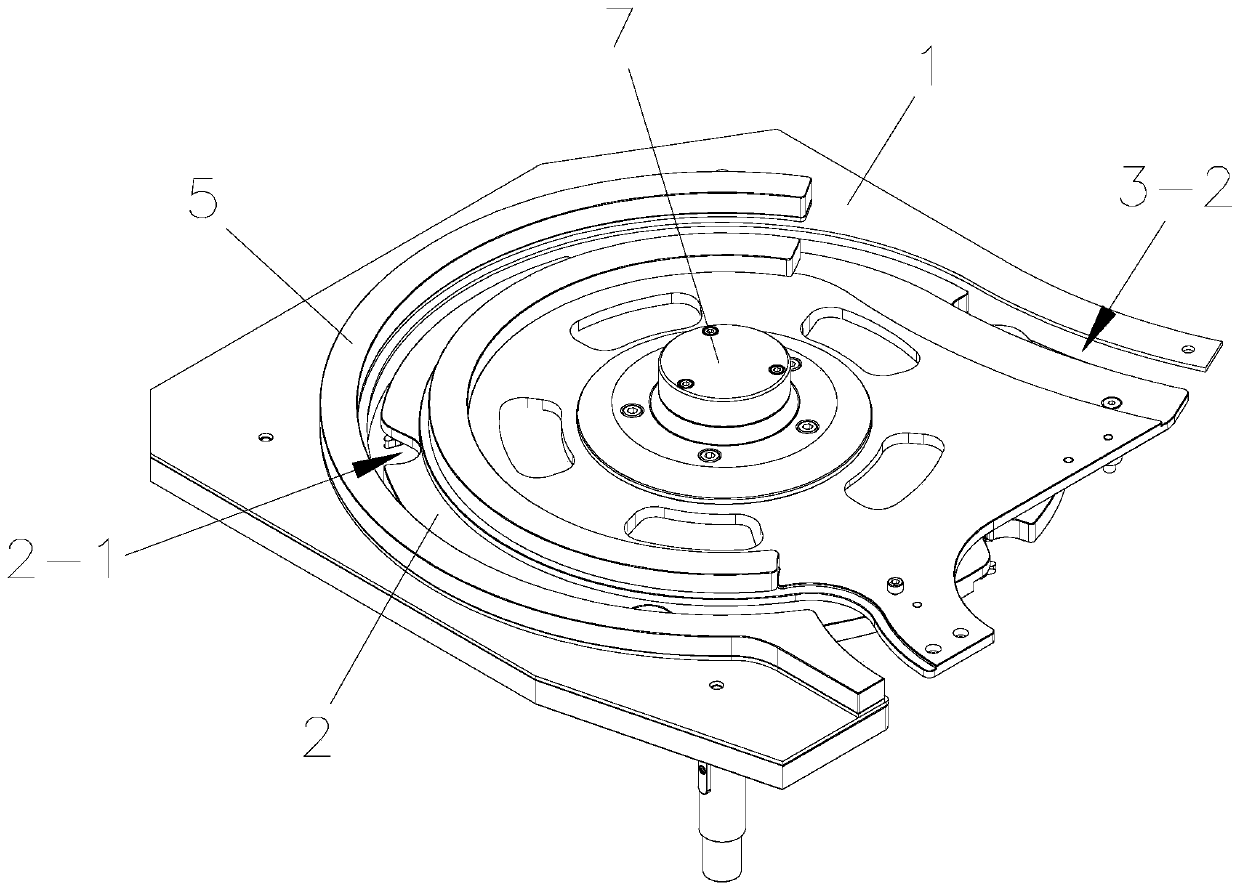

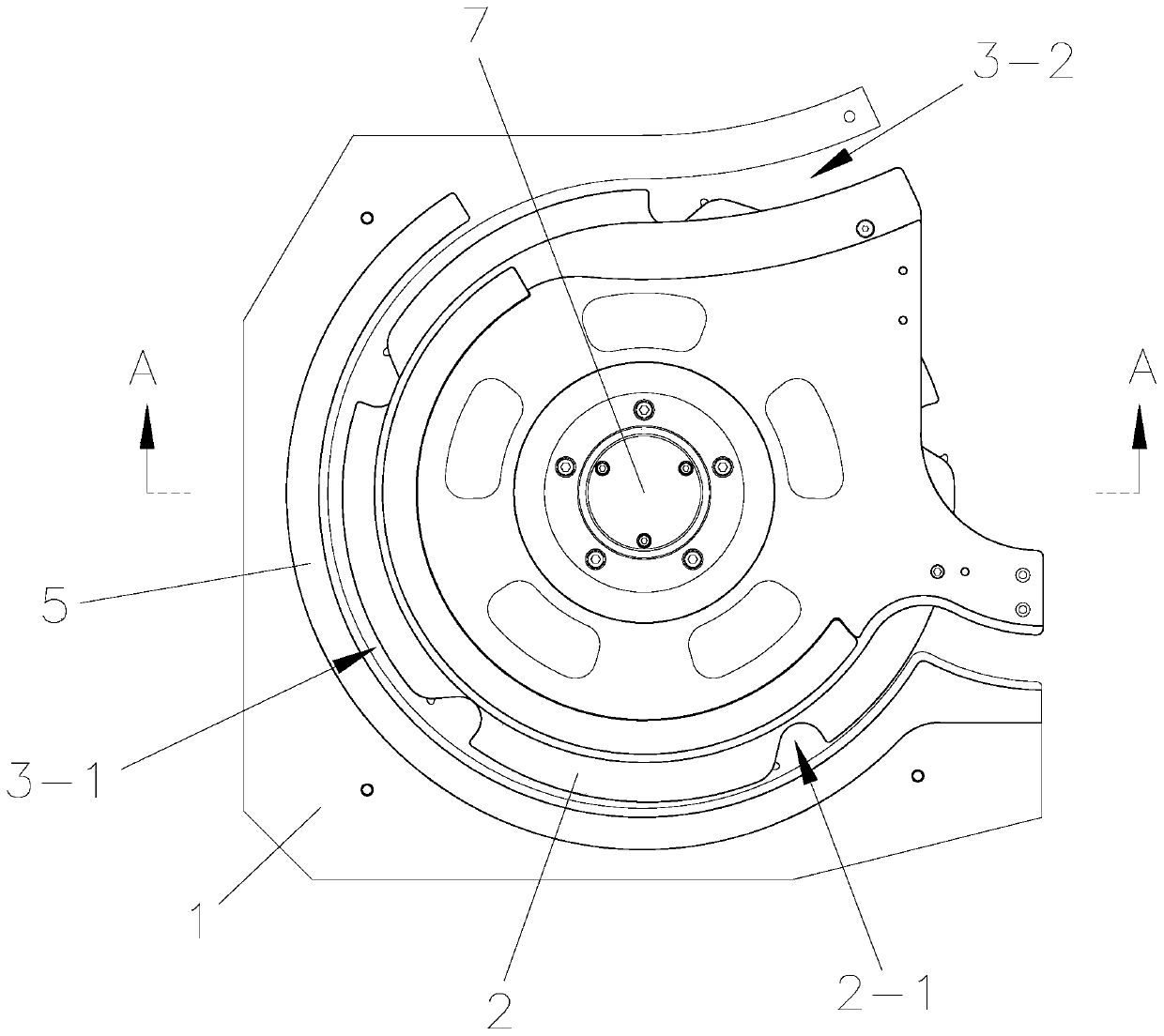

[0038] like figure 2 A stepped shaft-type parts conveying mechanism shown includes a base 1 and a moving plate 2 that rotates relatively along the base 1. The rotating shaft is installed on the base 1, and the moving plate 2 is fixedly installed on the rotating shaft, as shown in FIG. Figure 4 As shown, the base 1 is provided with a conveying guide rail for the movement of the pump head 6-3, both sides of the conveying guide rail on the base 1 are fixedly installed with limit guide rails 5, and the pump sleeve 6-1 is clamped between the two limit guide rails 5 between; the moving plate 2 is provided with a bayonet 2-1 for clamping the pump head 6-3, such as image 3 As shown, the bayonet 2-1 is a superior arc structure, the bayonet 2-1 moves out of the side of the pump head 6-3 and the moving plate 2 has an arc degree, the bayonet 2-1 has 5, and the 5 bayonets 2 -1 is evenly distributed along the circumference of the central axis of the moving plate 2, and the bayonet 2-1 i...

Embodiment 2

[0044] Compared with Embodiment 1, the difference between Embodiment 2 and Embodiment 1 is that the pressing assembly includes a slider 4-4, and the slider 4-4 is fixedly installed on the end of the claw 4-2 away from the limit plate 4-1, and the cam 4- The edge of 3 is provided with guide groove 4-3-1 in the peripheral direction, as Figure 10 and Figure 11 As shown, the slide block 4-4 is slidingly clamped in the guide groove 4-3-1, and the slide block 4-4 can always move along the edge of the cam 4-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com