High-precision full-automatic plate collecting and placing machine

A fully automatic and high-precision technology, which is applied in the direction of conveyor objects, object stacking, and object destacking, etc. It can solve problems such as the inability to adjust the direction of the board, fail to meet production needs, and damage to the board, so as to save production space. , Reduce the overall occupied area and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

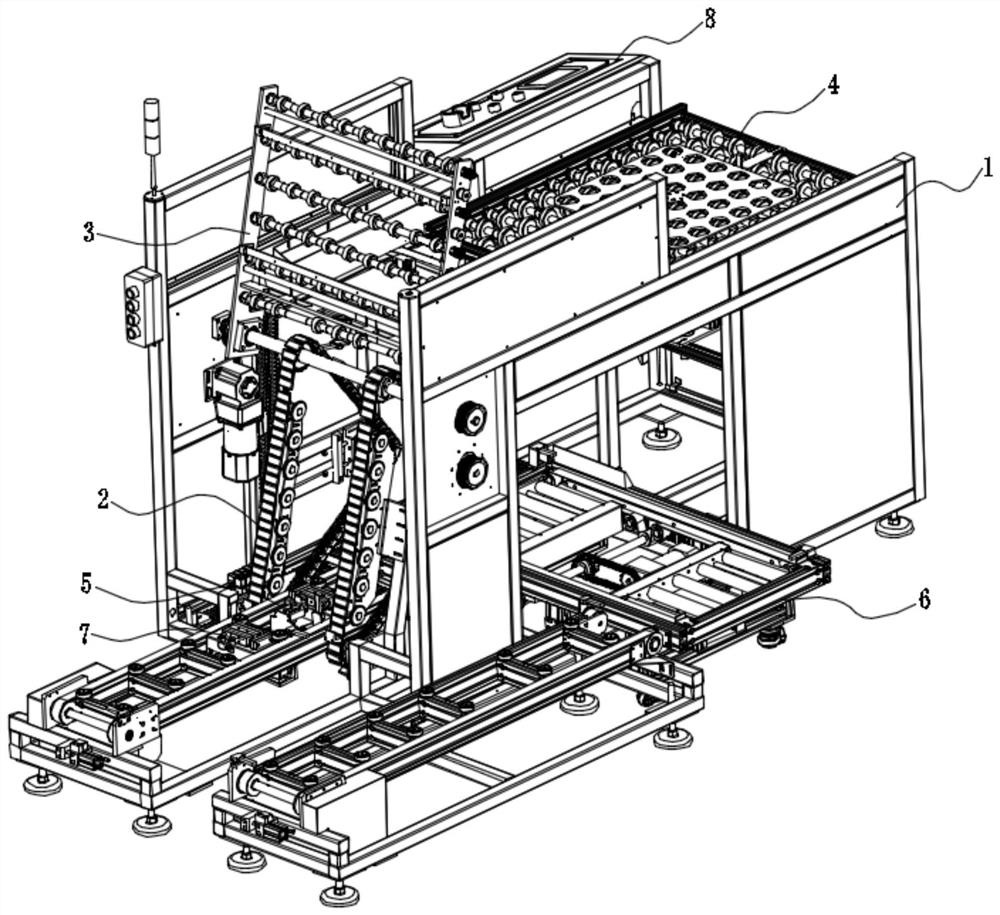

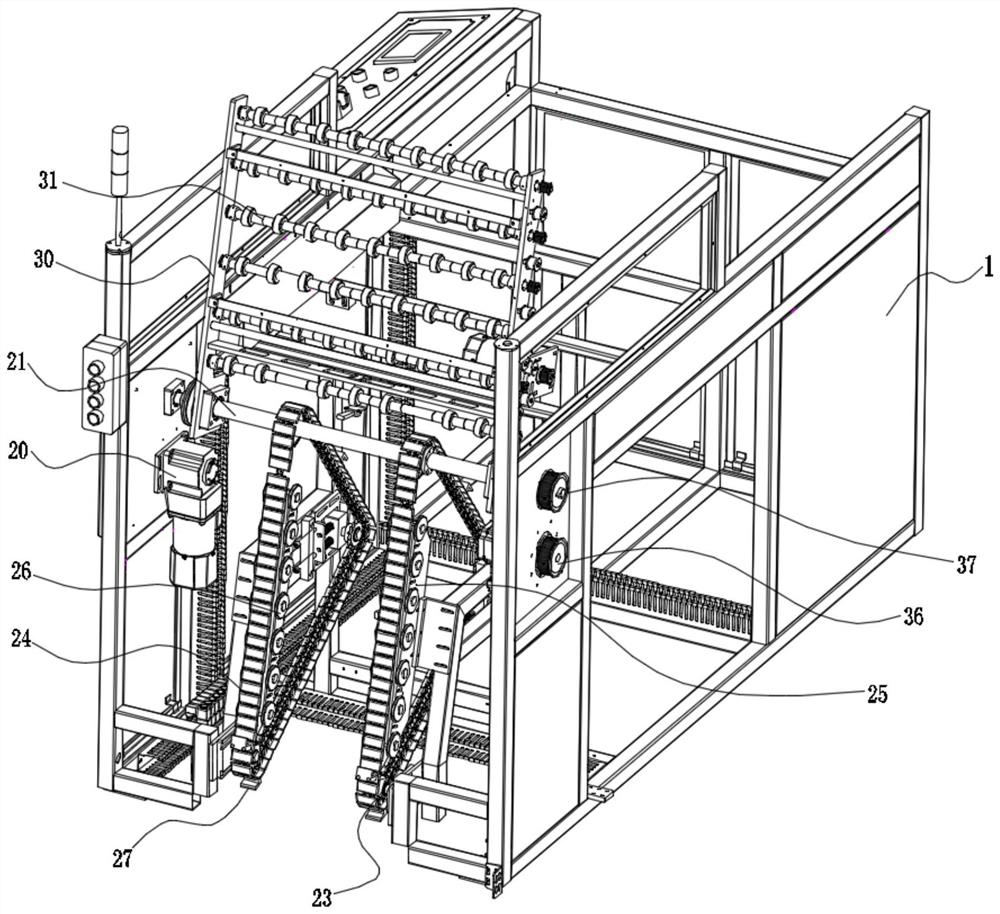

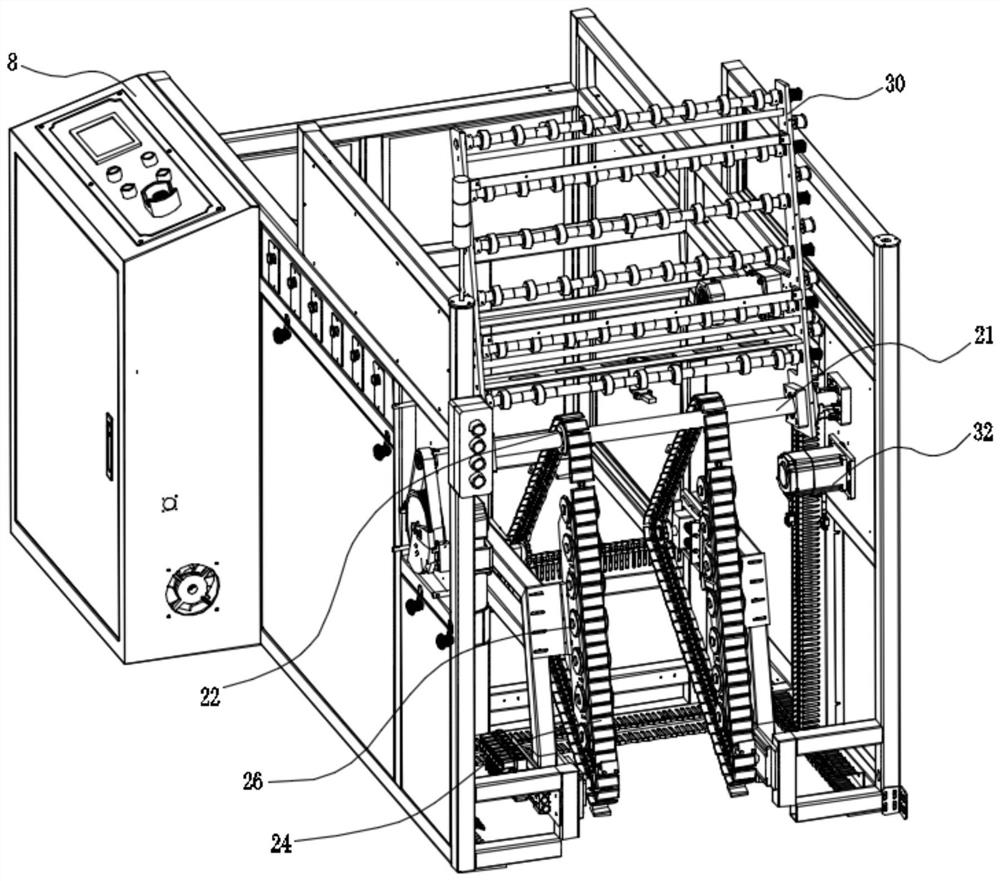

[0032] Please refer to Figure 1-Figure 10 , the present invention provides a high-precision full-automatic loading and unloading machine, including: a frame 1, a pick-and-place mechanism 2 installed on the frame 1, an overturning conveying mechanism 3, a feeding and discharging conveying mechanism 4, and a The material shifting mechanism 5 on the lower side of the fetching and discharging mechanism 2, the control box 8 arranged on one side of the frame 1; the control box 8 is provided with a display screen and operation buttons, which can be displayed through the display screen The operation of each mechanism in the invention is controlled by the operation button; the material shifting mechanism 5 is used to move the plate on the material rack to make it close to the pick-and-place mechanism 2 This side is tilted or used to move the plate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com