Steel bar conveying method

A technology of steel bars and conveying rollers, applied in the direction of conveyor objects, transportation and packaging, roller tables, etc., can solve problems such as low efficiency, achieve the effect of improving efficiency, reducing power requirements, and eliminating safety risks of manual hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to more fully explain the implementation of the present invention, the implementation examples of the present invention are provided, and these implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

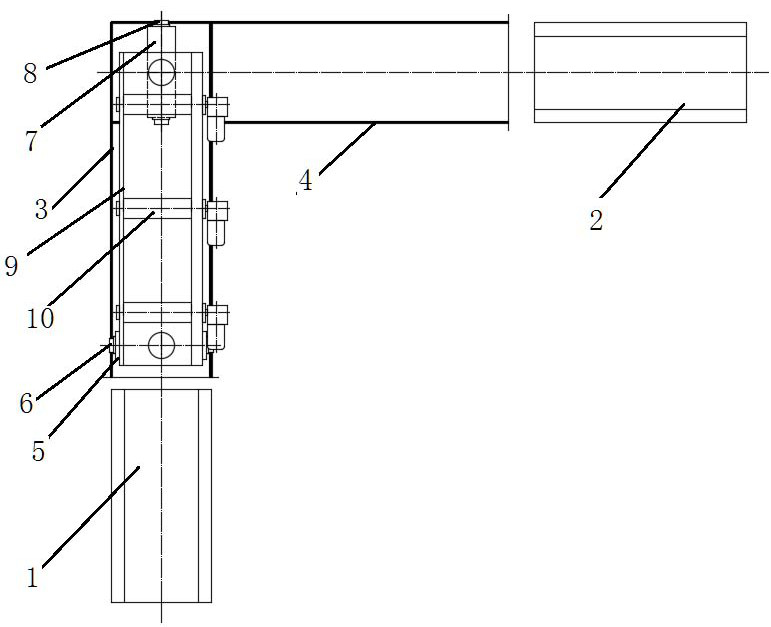

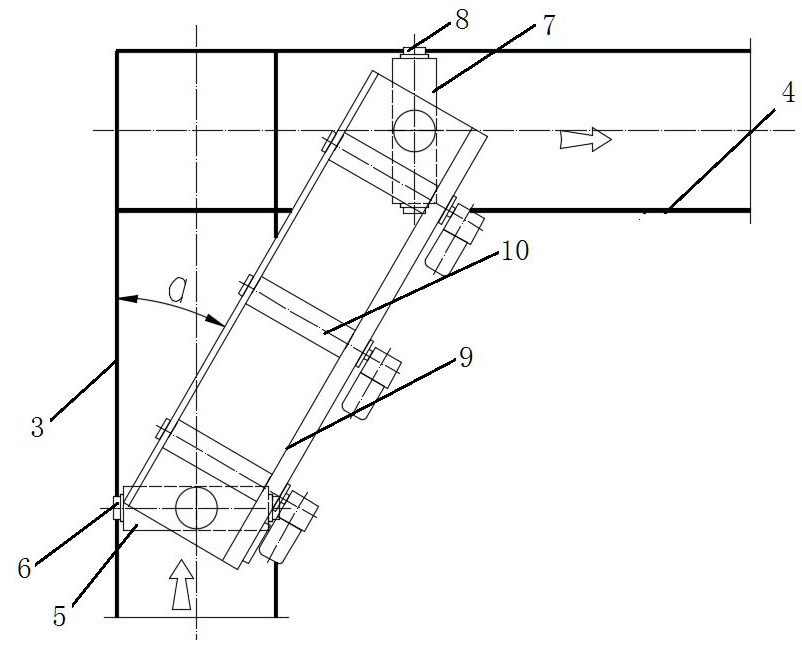

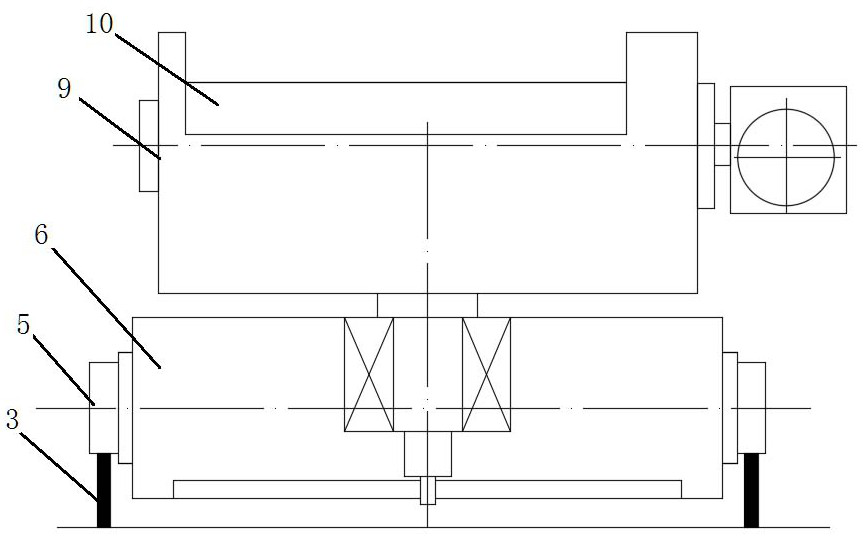

[0021] Each mark in the attached drawings is: 1: front conveyor roller table; 2: rear conveyor roller table; 3: track A; 4: track B; 5: drive box 1; 6: track wheel A; 7: drive box 2; 8: track wheel B; 9: turntable; 10: roller.

[0022] The definition of the front and rear directions in this application is: the direction of reinforcement delivery is the rear.

[0023] A steel bar conveying method, the conveying method is used for conveying bundled straight steel bars, the conveying method adopts a steel bar conveying device for conveying, and the described reinforcing bar conveying device includes a front section conveying roller table 1, a rear section Conveyor roller table 2, the front convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com