Sheet manufacturing apparatus

一种制造装置、薄片的技术,应用在薄片制造装置领域,能够解决纤维凝集、难筛堆积、成型等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Several embodiments of the present invention will be described below. The embodiments described below are modes for explaining examples of the present invention. The present invention is not limited to the following embodiments, and includes various modified forms within a range that does not change the gist of the present invention. It should be noted that not all the configurations described below are necessarily essential configurations of the present invention.

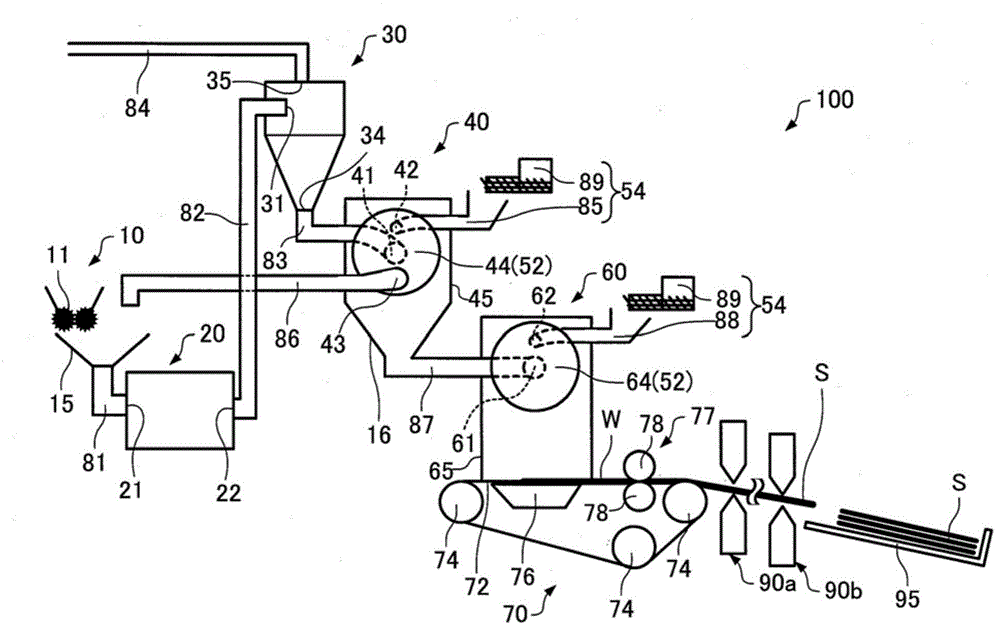

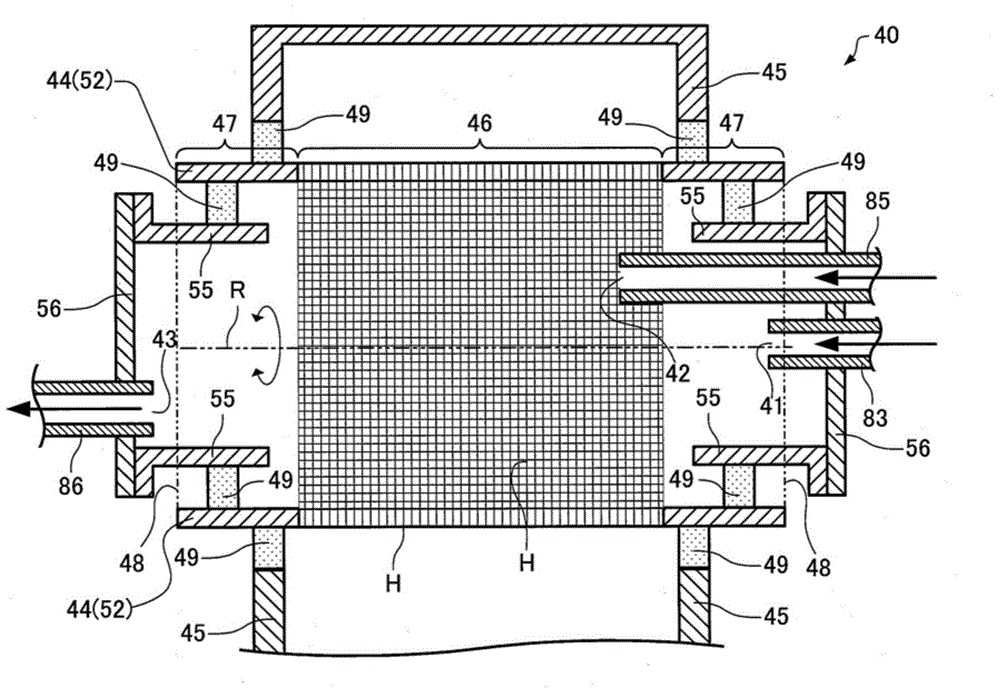

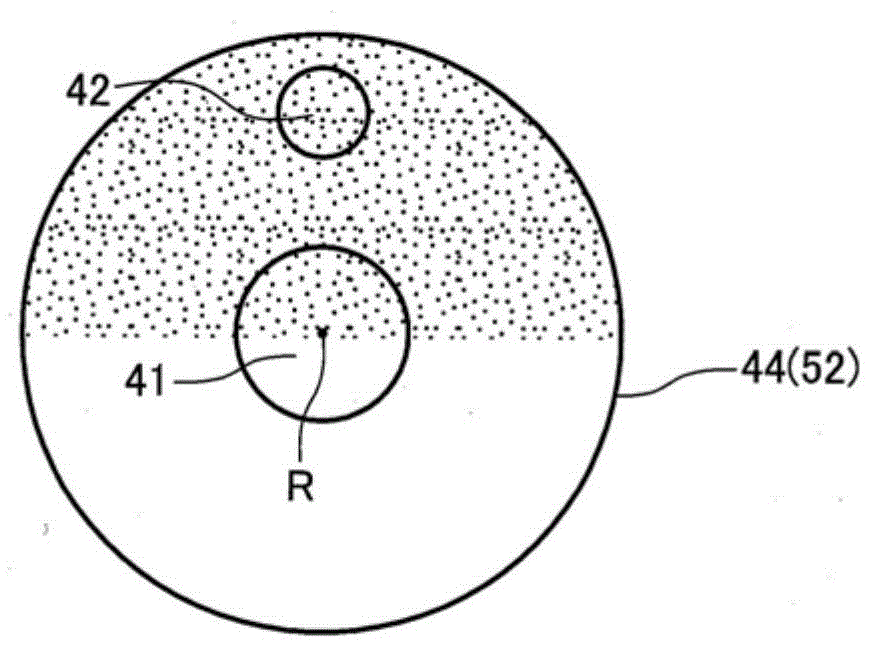

[0030] The sheet manufacturing apparatus 100 of this embodiment includes at least the defibrating unit 20 , the cylindrical unit 52 , the supply unit 54 , and the bonding unit 77 . Among them, since the cylindrical part 52 and the supply part 54 constitute each part of the sorting part 40 and / or the sorting part 60, they will be described in the items of the sorting part 40 and the sorting part 60.

[0031] figure 1 It is a schematic diagram of the sheet manufacturing apparatus 100 of this embodiment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com