Belt friction test device of belt friction test machine

A testing device and friction technology, applied in the direction of measuring device, mechanical device, force/torque/work measuring instrument, etc., can solve the problems of easy loosening and slipping, easy occurrence of tension, etc., to ensure stability and improve work. Efficiency, labor and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

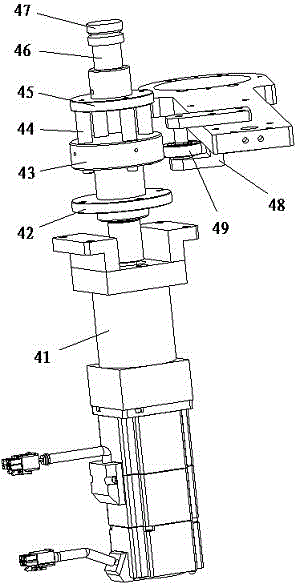

[0008] Such as figure 1 As shown, the belt friction testing device of a belt friction testing machine disclosed by the present invention, the belt friction testing device includes a belt friction testing motor 41 fixed to the lower end surface of the worktable, and also includes a belt fixed to the upper end surface of the worktable Friction test fixed seat 42, belt friction test fixed seat 42 is provided with belt friction test rotating disk 43, the output shaft of belt friction test motor 41 stretches in the belt friction test fixed seat 42, and tests the lower end of rotating disk 43 with belt friction Fixed connection, the upper end surface of the belt friction test rotating disk 43 is arrayed according to the center of the circle with a plurality of belt friction rotation support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com