Conveying belt sweeping device

A technology of cleaners and conveyor belts, used in conveyor objects, cleaning devices, transportation and packaging, etc., can solve the problems of reducing belt life, conveyor belt wear, and requiring a good environment, so as to reduce wear, improve service life, and improve The effect of the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

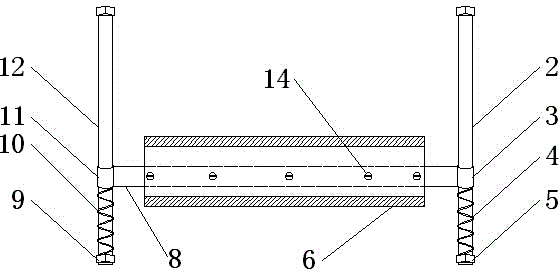

[0014] Embodiment one: if figure 1 As shown, a conveyor belt cleaner, the fixed frame is composed of a left bracket 12, a right bracket 2, a connecting plate 8 connecting the left bracket 12 and the right bracket 2, and the sleeve pipes 11, 3 welded at the two ends of the connecting plate 8 Be placed on the left bracket 12, the right bracket 2 and be slidably connected with the left bracket 12, the right bracket 2, the connecting plate 8 is screwed and fixed with the scraper 6 with the screw 14, the left bracket 12, the sleeve pipe 11,3 bottom, Be with spring 10,4 on the right moving frame 2, left support 12, right support 2 lower ends of spring 10,4 bottoms are screwed with adjusting nut 9,5.

Embodiment 2

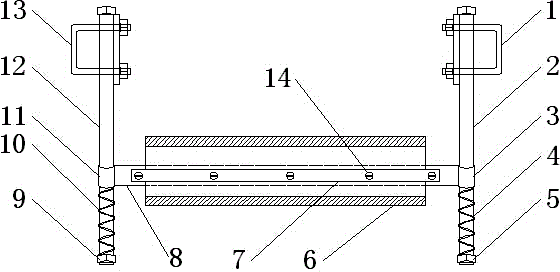

[0015] Embodiment two: if figure 2 As shown, on the basis of the first embodiment, the scraper 6 is arranged between the connection plate 8 and the splint 7 , and the splint 7 and the scraper 6 are fixed on the connection plate 8 by screws 14 .

Embodiment 3

[0016] Embodiment 3: On the basis of Embodiment 1 or 2, let the upper and lower ends of the scraper 6 be higher than the upper and lower ends of the connecting plate 8 and the splint 7 . When the upper end of the scraper 6 is seriously worn, turn the scraper 6 upside down, which can save the scraper material and improve the utilization rate of the scraper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com