Image generating device, defect inspecting device, and defect inspecting method

An image generation device and image generation technology, which are applied in image enhancement, image analysis, measurement devices, etc., can solve problems such as undetectable defects and limited defect detection capabilities, and achieve the effect of preventing repeated detection and high detection capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

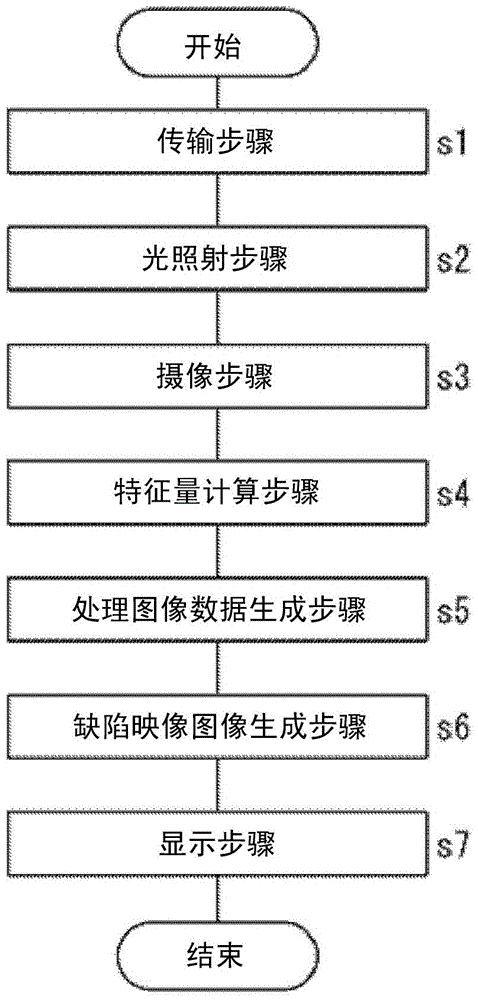

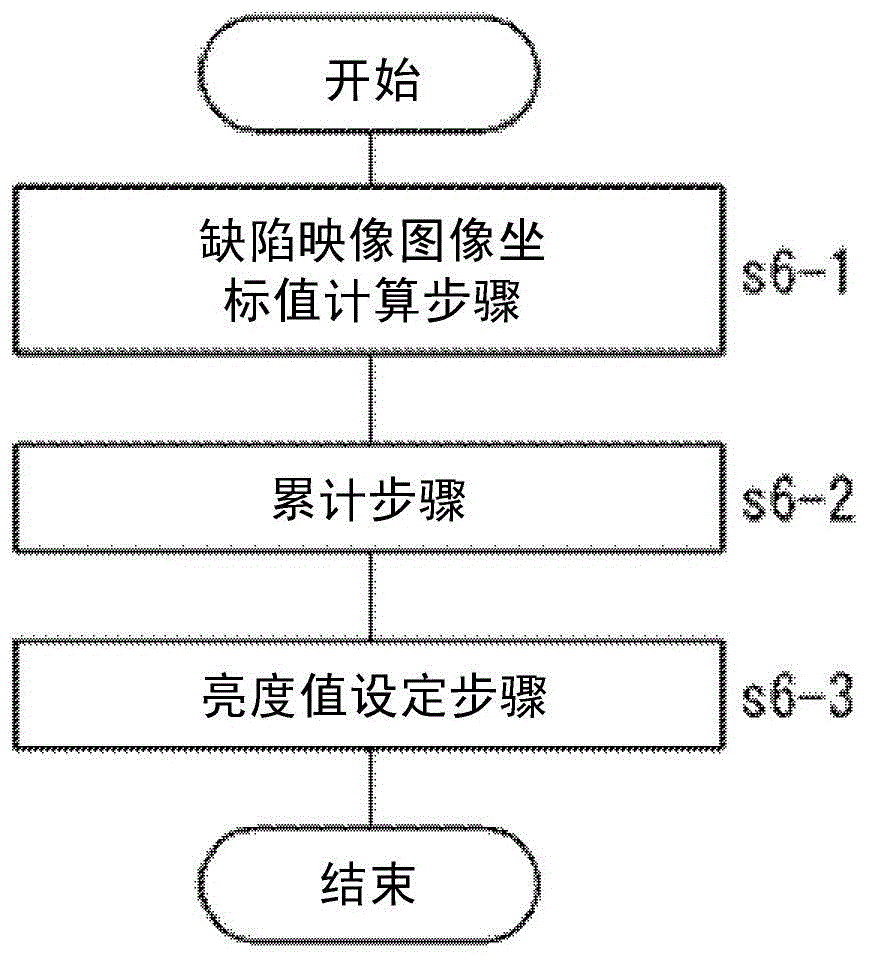

[0068] Figure 1A and 1B is a flowchart showing the steps of the defect inspection method according to one embodiment of the present invention. The defect inspection method of this embodiment includes Figure 1A The transmission step s1 , the light irradiation step s2 , the imaging step s3 , the characteristic amount calculation step s4 , the processed image data generation step s5 , the defect map image generation step s6 , and the display step s7 are shown. In addition, the defect map image generating step s6 includes Figure 1B The defect map image coordinate value calculation step s6-1, accumulation step s6-2, and brightness value setting step s6-3 are shown.

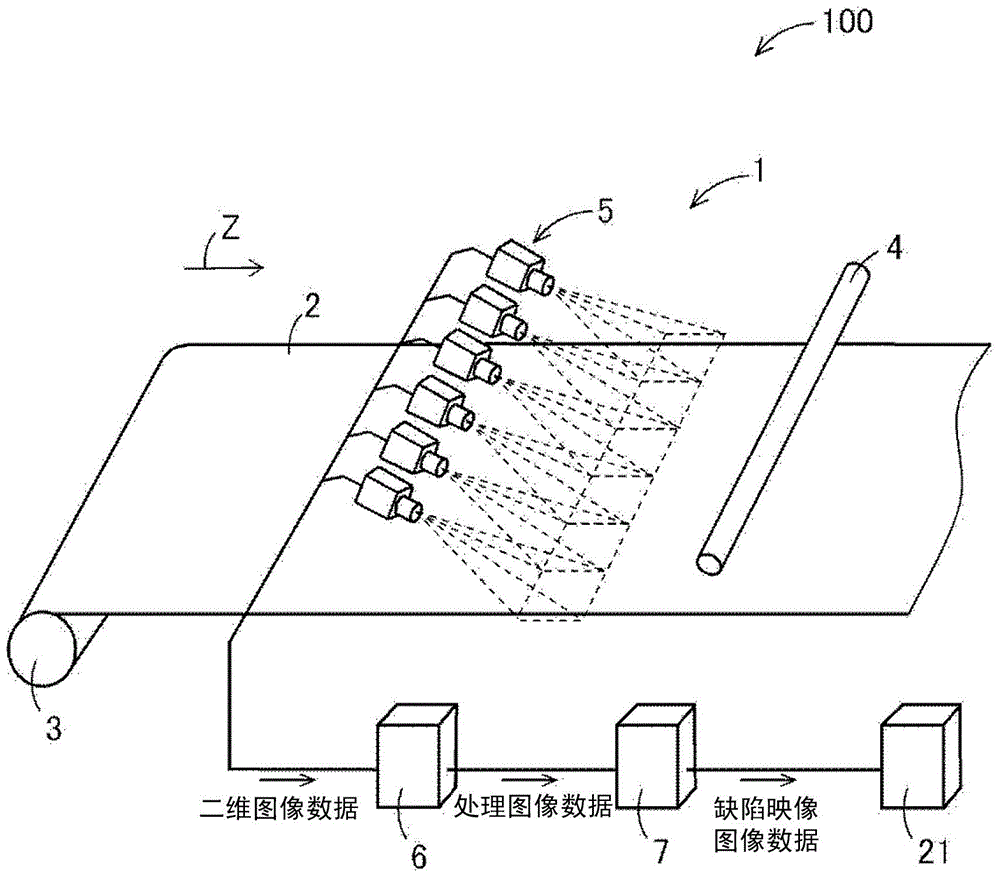

[0069] figure 2 It is a schematic diagram which shows the structure of the defect inspection apparatus 100 which concerns on one Embodiment of this invention. image 3 It is a block diagram showing the configuration of the defect inspection apparatus 100 . The defect inspection device 100 of the present embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com