Top cover stay positioning tool

A technology for positioning tooling and top covers, which is applied to workpiece clamping devices, manufacturing tools, hand-held tools, etc., and can solve problems such as easy installation of top cover stays, unreliable positioning, and insufficient assembly consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

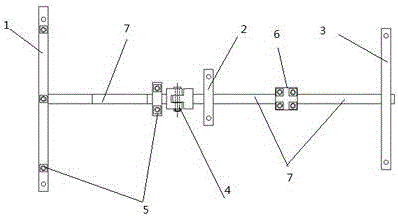

[0017] The roof stay positioning tool includes: the first positioning bar 1 positioned on the main body, the second positioning bar 2 and the third positioning bar 3 positioned on the roof rear stay; as for the second positioning bar 2 and the first positioning bar A rotating shaft 4 between positioning bars 1, and adsorption components distributed on both sides of the rotating shaft 4. The first positioning bar 1 is located in the U-shaped hole of the rear beam of the top cover; the second positioning bar 2 and the third positioning bar 3 are located in the two process holes in the middle of the top cover rear stay; due to another set of process holes in the top cover rear stay If the hole spacing is too large, if it is used for positioning, the length of the middle positioning bar is too large, which will be inconvenient during use, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com