An automatic filament tensioning device and method with controllable tension force

An automatic tensioning device and tensioning force technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low production efficiency and poor consistency, improve assembly efficiency, ensure assembly consistency, and ensure assembly. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Attached below Figure 1-Figure 5 and technical solutions to further illustrate the present invention, but not limit the present invention.

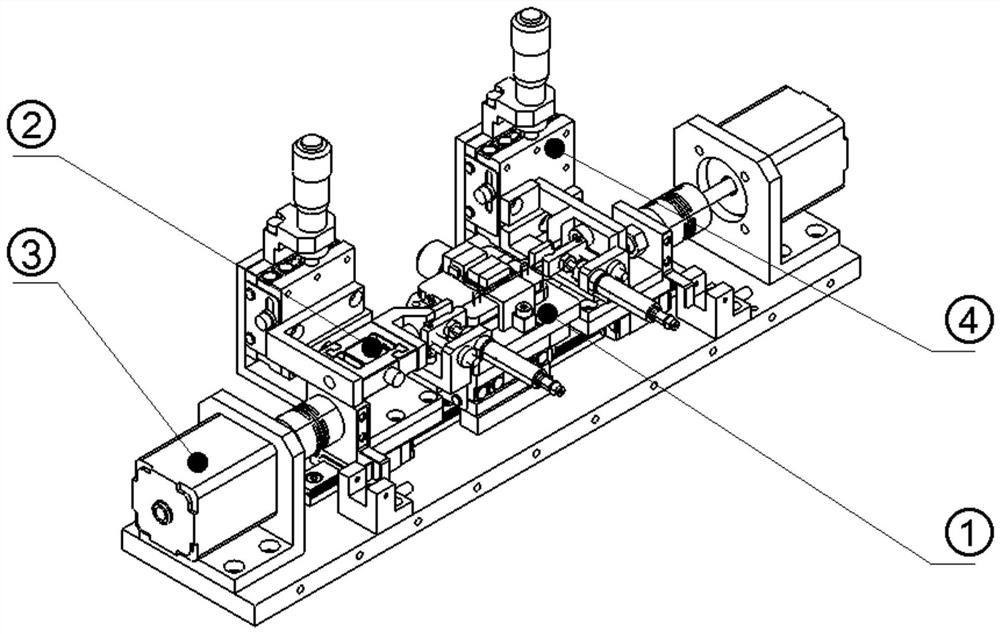

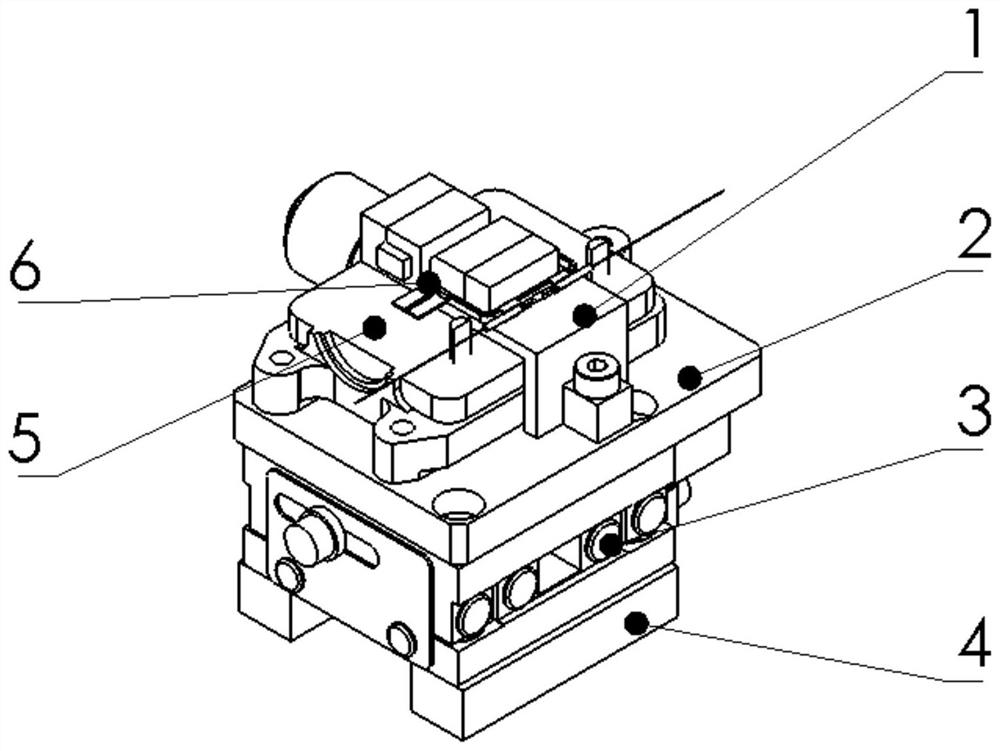

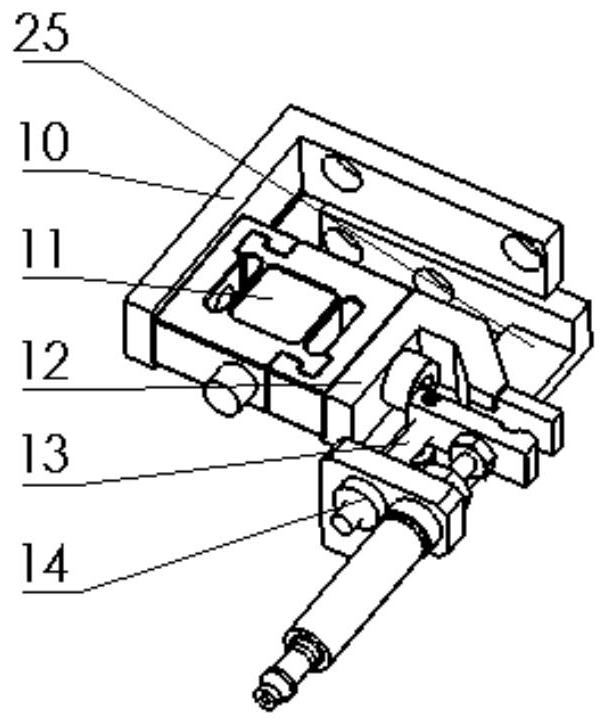

[0031] Such as figure 1 The shown discloses an automatic filament tensioning device with controllable tension of the present invention. The automatic filament tensioning device with controllable tension includes a feeding unit ①, a filament clamping unit ②, a tensioning Force control unit ③ and two filament position adjustment units ④; the feeding unit ① is used to install the parts to be assembled and adjust the relative position of the parts and the filaments in the X direction; the filament clamping unit ② is used to Realize the automatic clamping of the filament; the tension control unit ③ effectively controls the tension of the filament through the micro force sensor 11, and adjusts the position of the filament in the Y direction; the filament position adjustment unit ④ has a total Two, used to adjust the position of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com