A vision-guided method for material positioning of elevator door panels

A positioning method and vision-guided technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of manipulator mission failure, limit the application of manipulator arms, etc., to achieve the effect of improving intelligence and flexibility, and ensuring accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

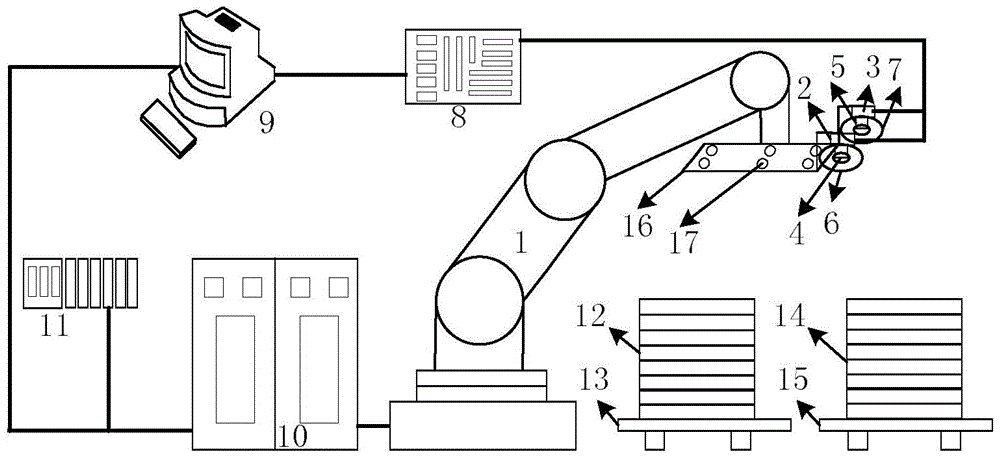

[0018] The overall structure of the feeding system includes a vision positioning unit, a robotic arm control unit and an upper computer unit. The visual positioning unit is composed of the first industrial camera and the second industrial camera, the industrial lens 4 and the industrial lens 5, the red ring light source 6 and the red ring light source 7 and the image acquisition card 8; the mechanical arm control unit is mainly composed of PLC11, mechanical arm 1, The manipulator control cabinet 10, the suction cup support 16 and the suction cup 17 are composed; the host computer is the industrial computer 9.

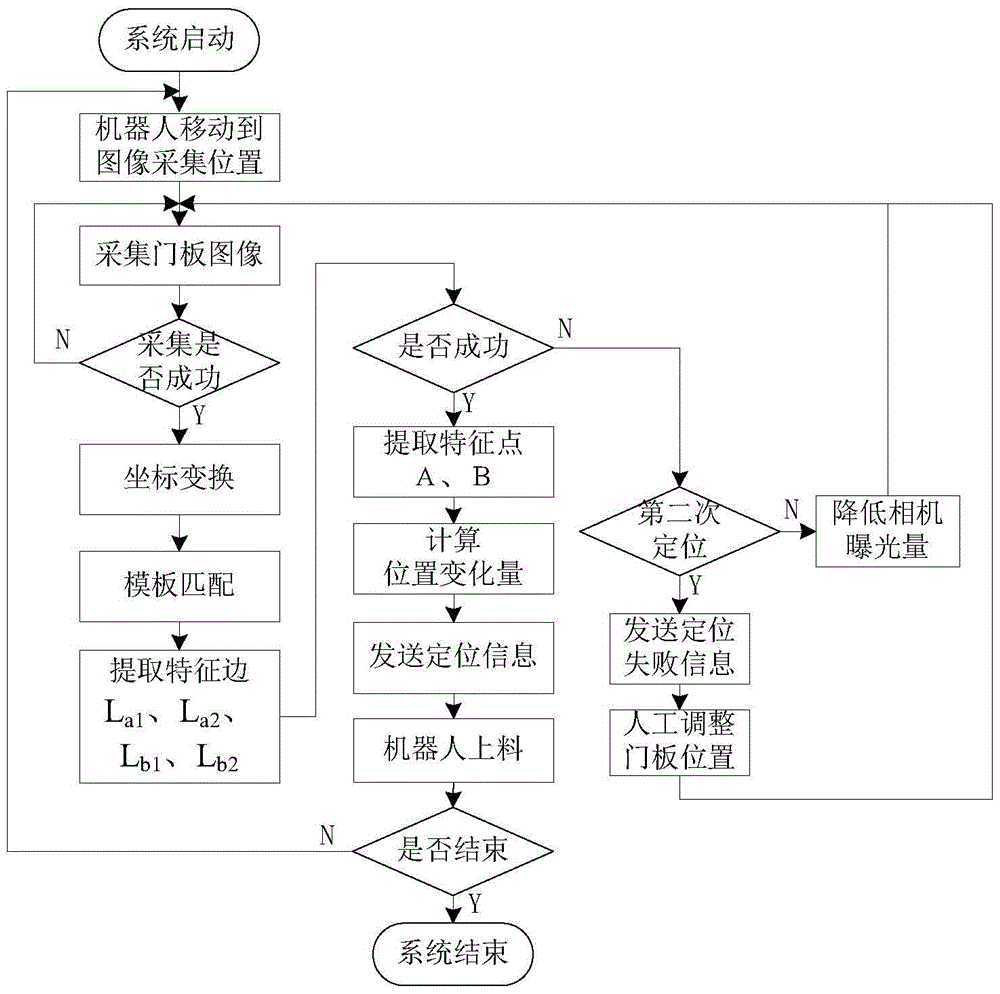

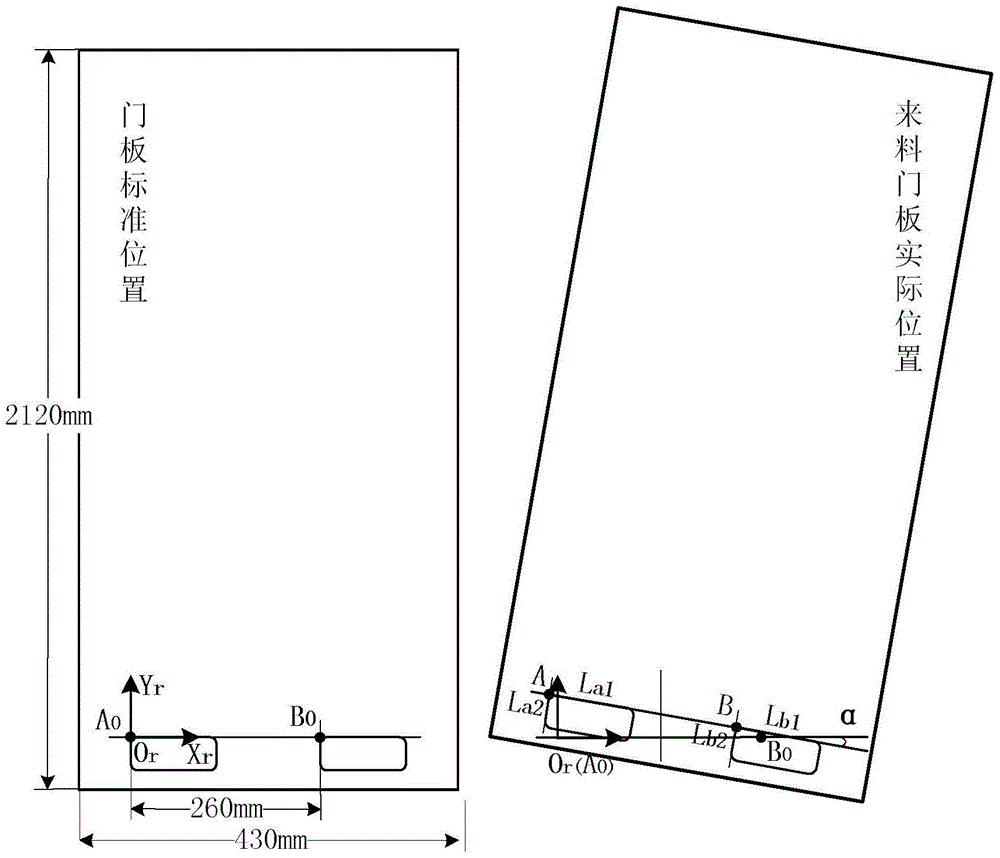

[0019] attached figure 2 It shows a material feeding flow chart of an elevator door panel material positioning method under the guidance of vision. The elevator door panels produced by welding and assembling in the previous producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com