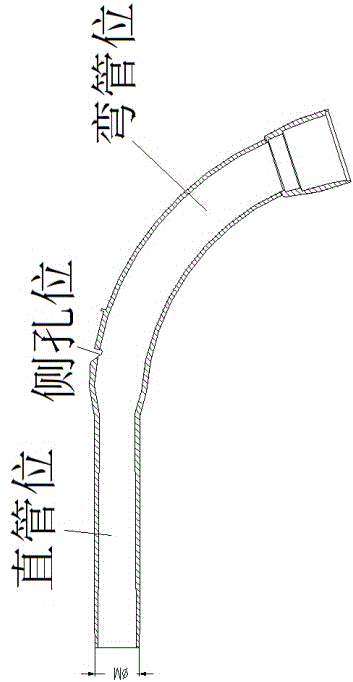

Injection mold of large-angle arc circular pipe

An injection mold, large-angle technology, applied in household appliances, other household appliances, applications, etc., can solve the problems of mold design and processing difficulties, difficult to ensure product molding quality, etc., to achieve compact structure, stable work, and guaranteed molding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

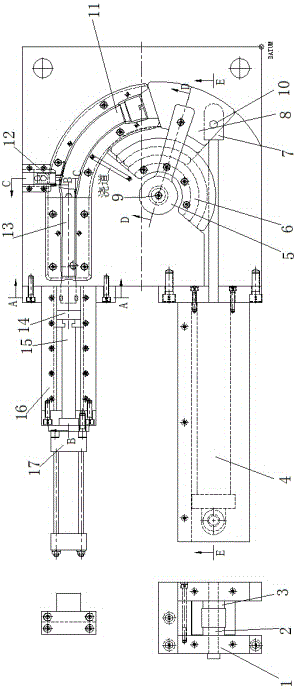

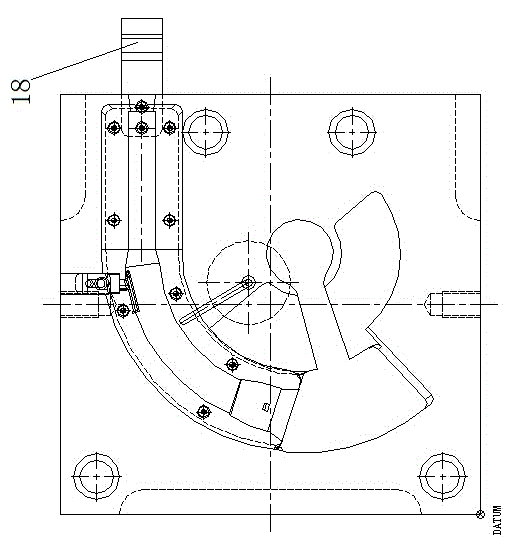

[0019] Figure 1-9 Shown is the relevant explanatory diagram of the present invention; a large-angle arc circular tube injection mold, including an elbow core-pulling cylinder bracket 1, a rotating pin 2, a wear-resistant ring 3, a core-pulling cylinder 4, a slider rotating handle 5, Guide groove block 6, movable coupling block 7, slider body 8, rotating center pin 9, coupling block center pin 10, elbow slider head 11, side core-pulling slider 12, straight tube slider head 13, straight tube pumping Core slider body 14, cylinder pull rod 15, straight tube core-pulling cylinder support 16, straight tube core-pulling cylinder 17, straight tube slider body pressing block 18, sprue bushing 19, positioning ring 20, fixed template 21, movable template 22. Reset lever 23, reset lever spring 24, thimble cover plate 25, thimble push plate 26, lower mold seat plate 27, cavity insert 28, core insert 29, such as figure 2 , image 3 , Figure 4 shown.

[0020] The mold frame structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com