Oblique shoemaking cloth treatment apparatus

A kind of processing equipment, inclined technology, which is applied in the field of inclined cloth processing equipment for shoemaking, can solve the problems such as insufficient equipment, and achieve the effect of reducing production cost, simplifying structure and reducing power expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

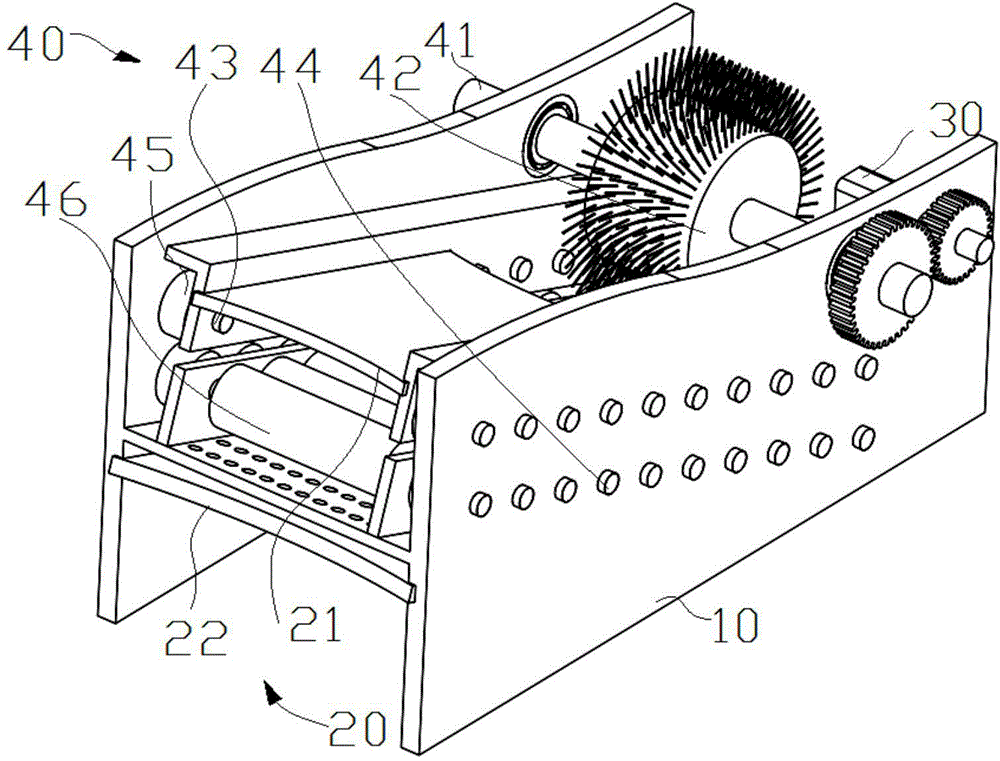

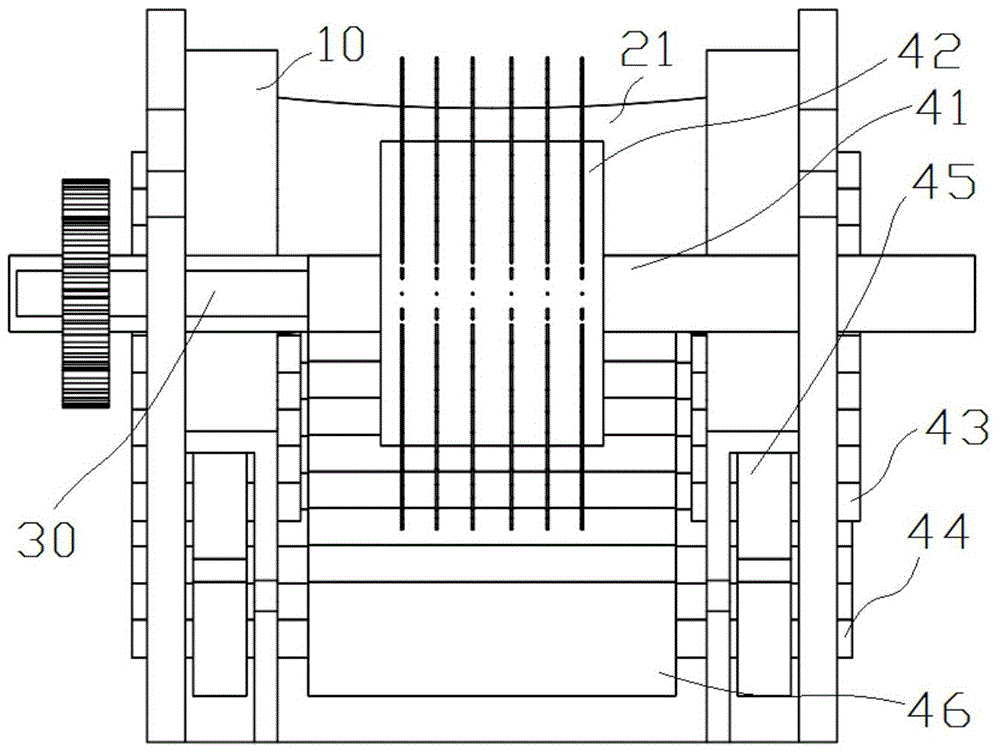

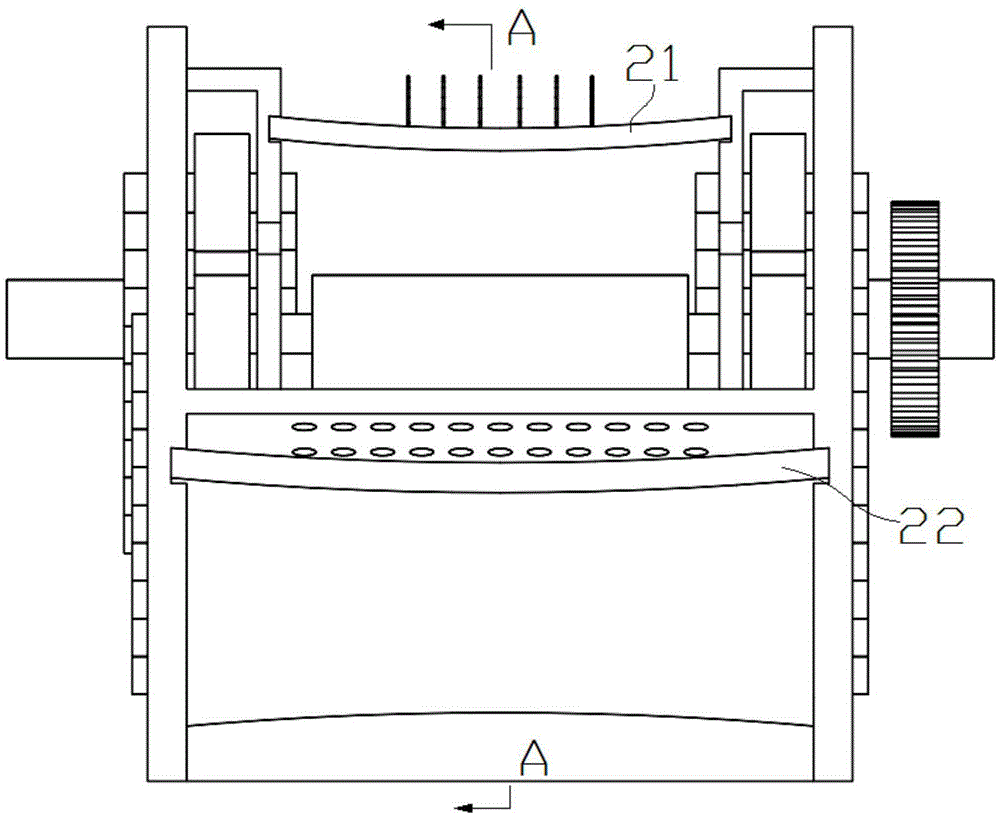

[0020] Such as Figure 1 to Figure 5 , an inclined cloth processing equipment for shoemaking, comprising a frame 10, a heating plate assembly 20, a motor 30, and a conveying assembly 40; The heating plate 21 is embedded in the L-shaped plate groove 131 of the frame 10, and the lower heating plate 22 is embedded between the first vertical plate groove 111 and the second vertical plate groove 121 of the frame 10; the heating plate assembly 20 is installed and transported The conveying roller 45 and the middle roller 46 of the assembly 40, the conveying roller 45 is installed symmetrically on the first vertical plate 11 and the second vertical plate 12 of the frame 10 respectively, and the conveying roller 45 on each vertical plate is arranged up and down It is two rows, and the number of 45 conveying rollers in each row is ten, and the two conveying rollers 45 and the middle roller 46 of the lower part are jointly sleeved on the long conveying shaft 44, and the long conveying sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com