A new type of circular steel pipe pier

A technology of round steel pipes and bridge piers, which is applied in the fields of steel bridge piers and civil engineering in bridge engineering. It can solve problems such as insufficient shear strength, insufficient bending resistance design of bridge piers, and difficult repair and use, so as to speed up road repair and shorten traffic control time. , The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

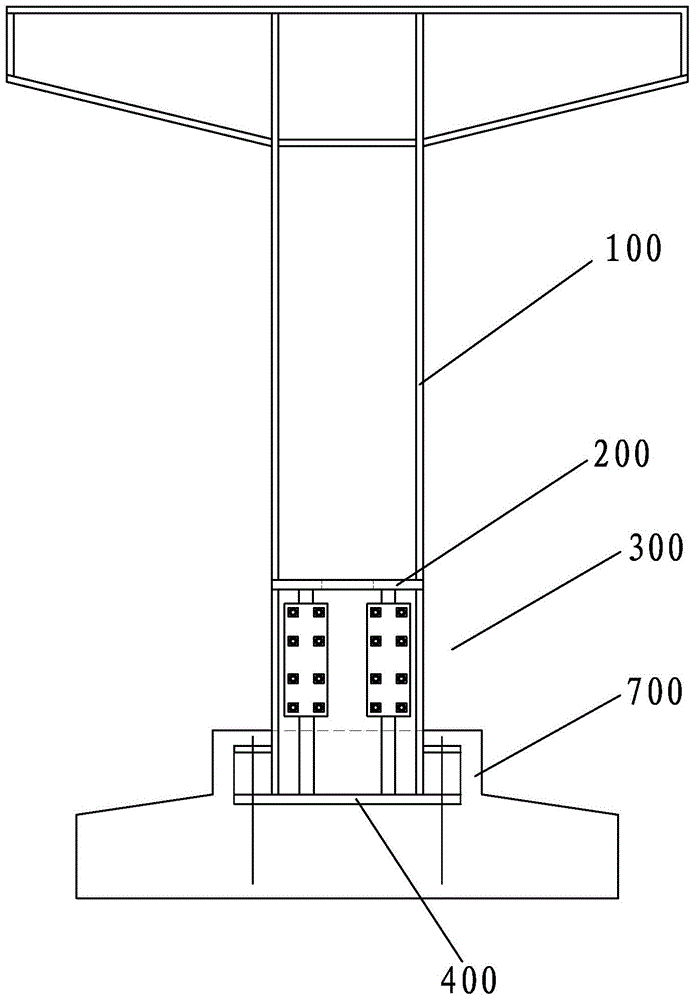

[0025] The invention provides a novel circular steel pipe pier, such as figure 1 As shown, it includes a circular steel pipe pier body 100 , a diaphragm 200 , a buckling-resistant energy-dissipating shell 300 and a bottom plate 400 welded together sequentially from top to bottom.

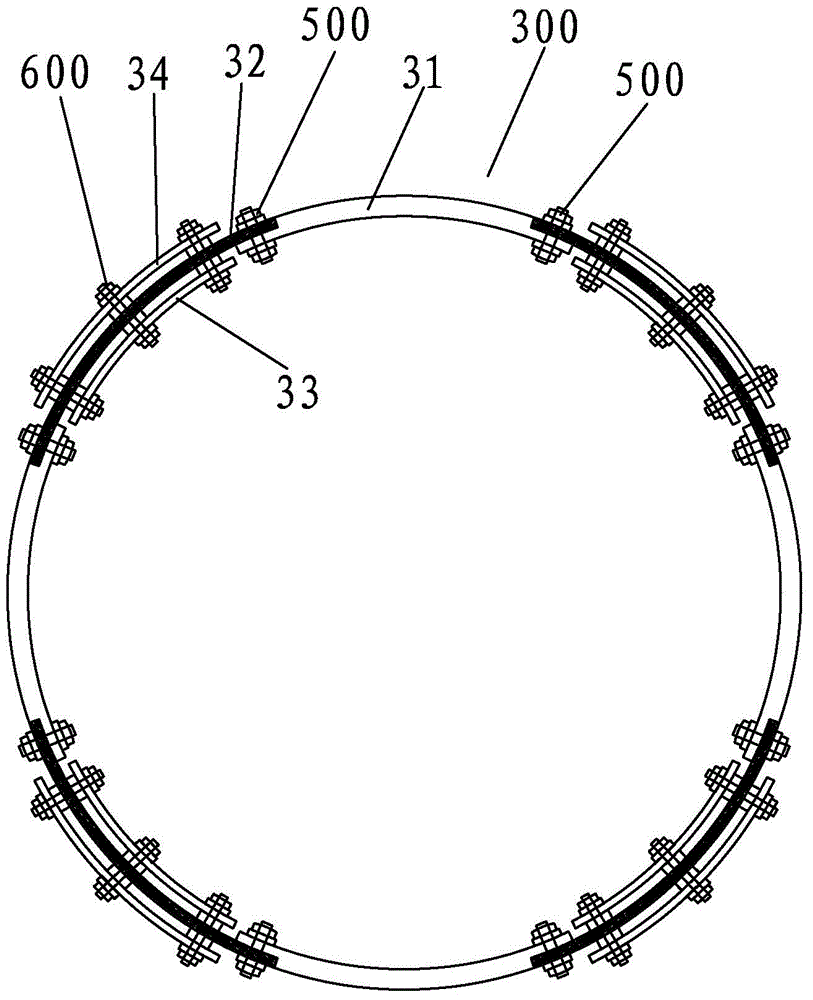

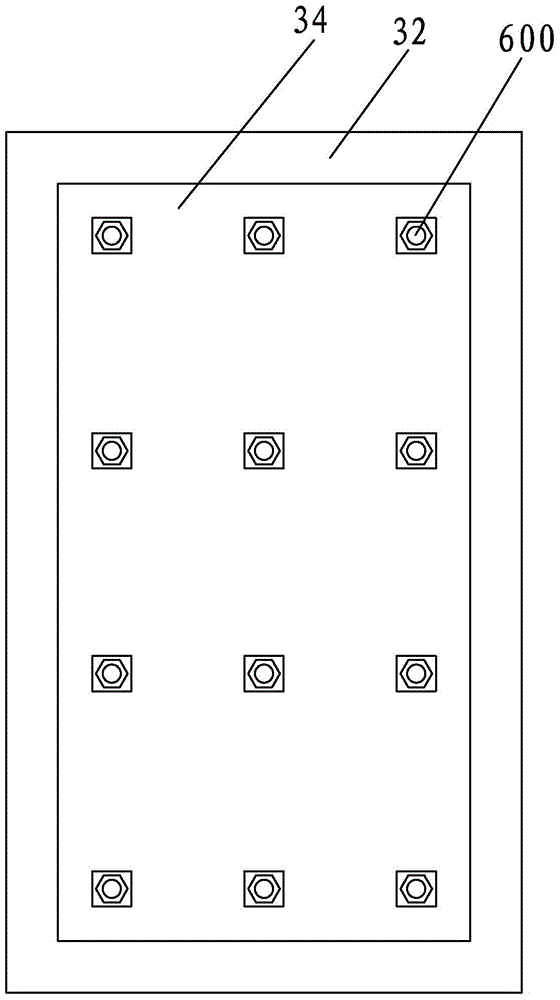

[0026] The buckling-resistant energy-dissipating shell 300 has a hollow cylindrical shape matching the shape of the round steel pipe pier body 100, the diaphragm 200 is a circular plate matching the shape of the round steel pipe pier body 100, and the round steel pipe pier body 100 and The anti-buckling energy-dissipating shell 300 is welded together through the transverse diaphragm 200, which can ensure the smooth force transmission between the circular steel pipe pier body 100 and the anti-buckling energy-dissipating shell 300, forming a whole to jointly resist external loads; Self-weight and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com