Fabricated circular steel tube energy-dissipating support

A technology of energy-dissipating supports and round steel pipes, applied in the field of building shock absorption, can solve the problems of high replacement and maintenance costs, loss of inner core, etc., achieve good low-cycle fatigue resistance, improve ductility, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

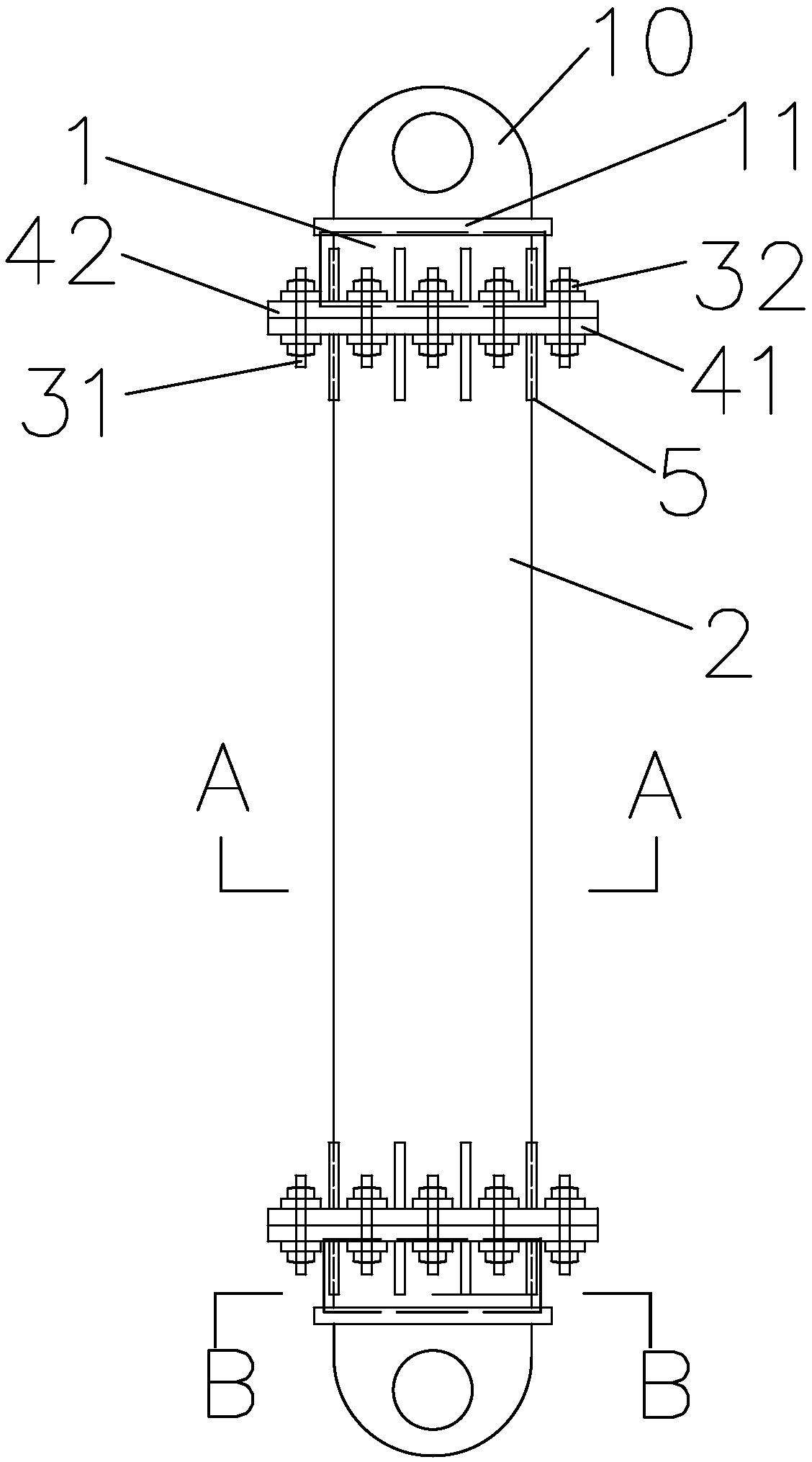

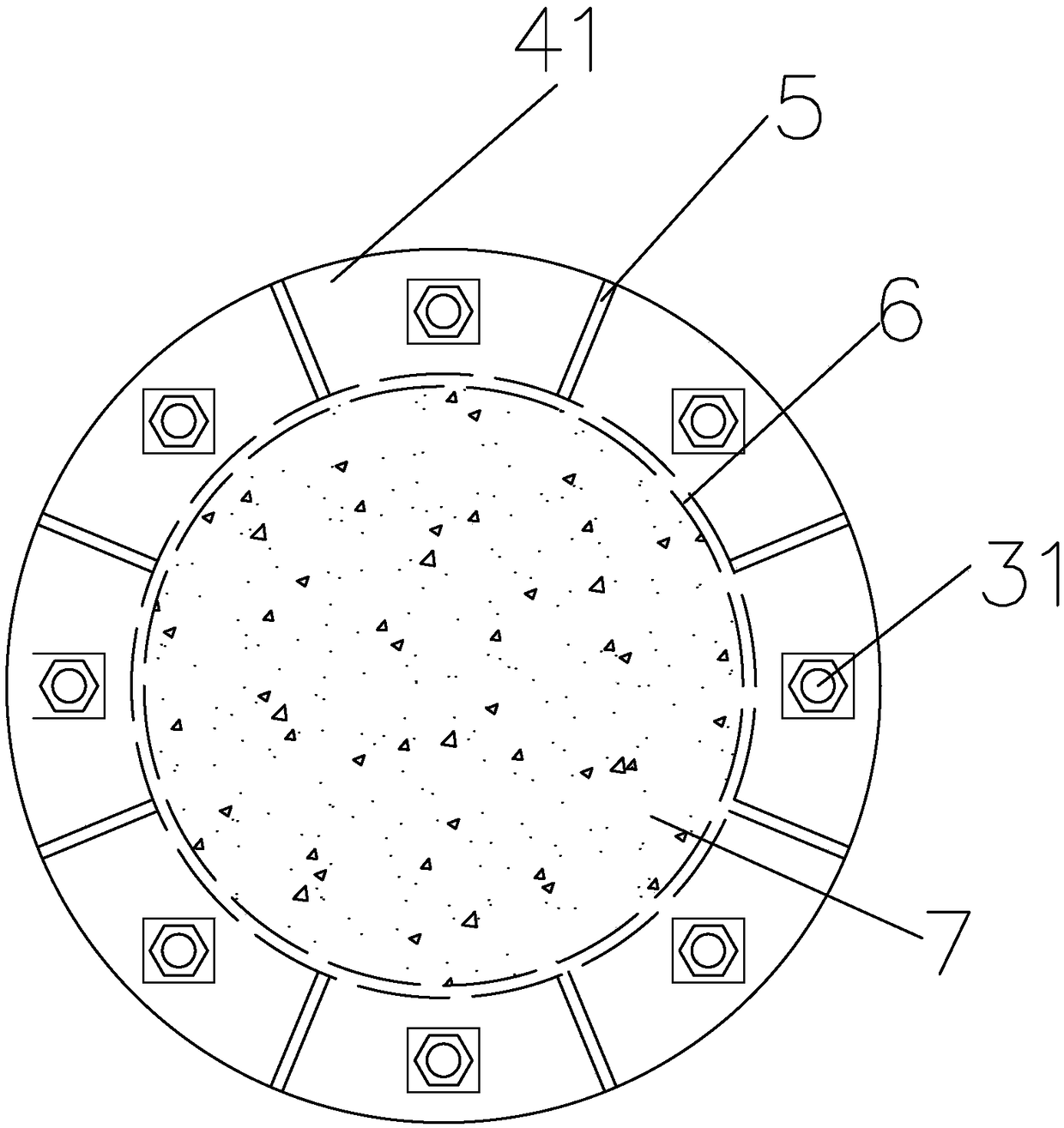

[0027] Such as Figure 1-5 An assembled round steel pipe energy-dissipating support is shown, including energy-dissipating member 1, support body 2, bolt 31, nut 32, first end plate 41, second end plate 42, stiffener 5, baffle plate 11 and There are two connecting plates 10 and two energy-dissipating components 1, and the two energy-dissipating components 1 are respectively detachably arranged at both ends of the supporting body 2;

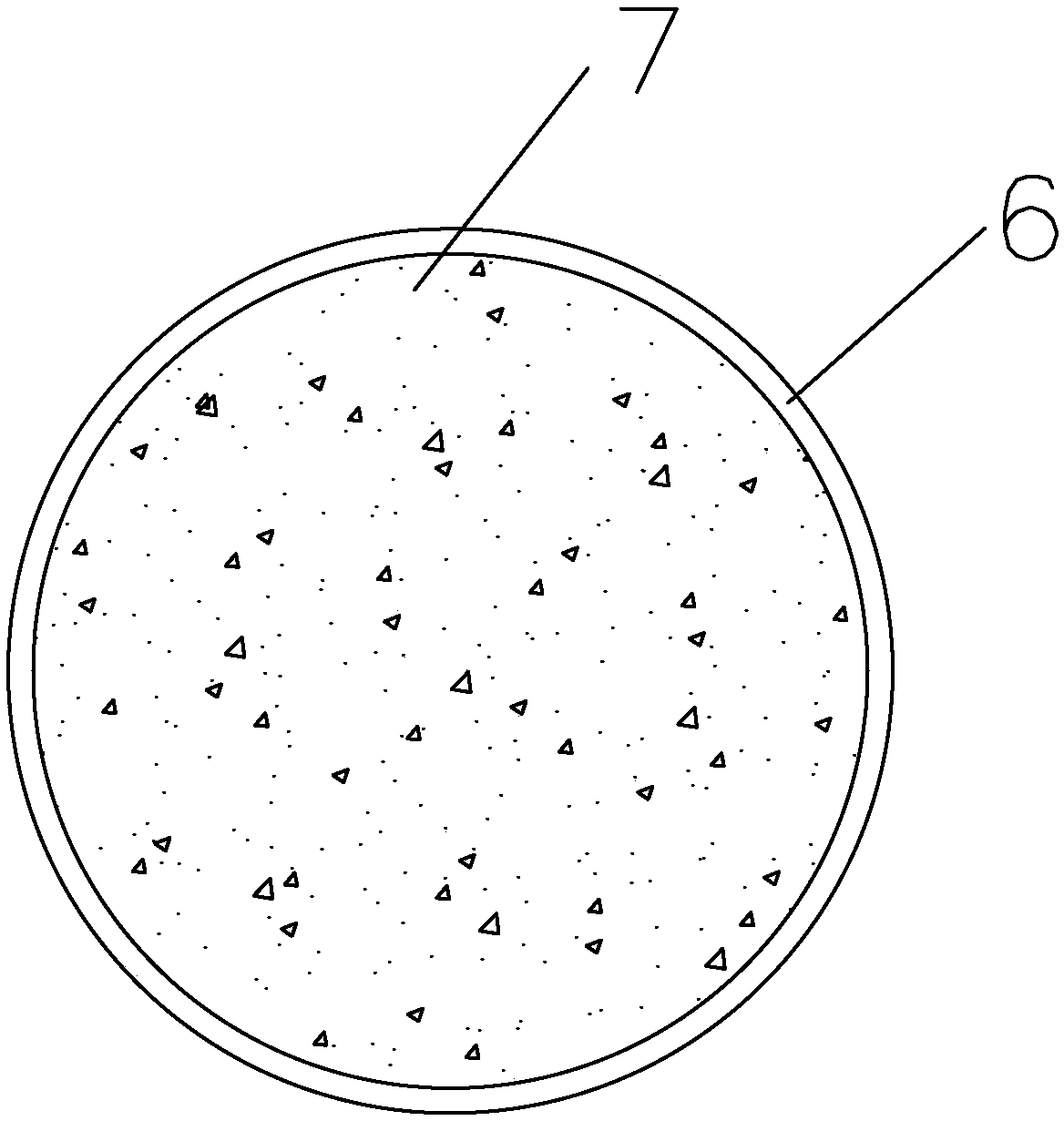

[0028] The supporting body 2 includes a peripheral steel pipe 6 and a filler 7, and the filler 7 is filled in the peripheral steel pipe; specifically, the material of the peripheral steel pipe 6 is an ordinary carbon steel Q235 steel pipe, and the shape is a hollow round steel pipe structure, and the inside of the peripheral steel pipe 6 is uniform The filler 7 is filled with conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com