Pneumatic hydraulic three-position five-way reversing valve

A three-position five-way, pneumatic-hydraulic technology, applied in the field of hydraulic valves, can solve the problems that the manual hydraulic reversing valve cannot meet the requirements of the automatic hydraulic system, the electromagnetic switch has high requirements, and affects the service life, etc., and achieves simplified control methods and ingenious structures. Compactness and production cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

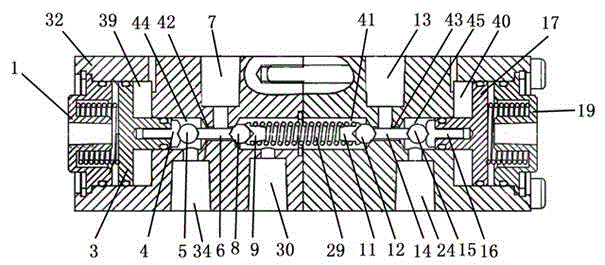

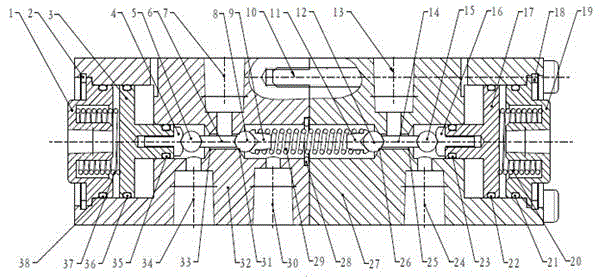

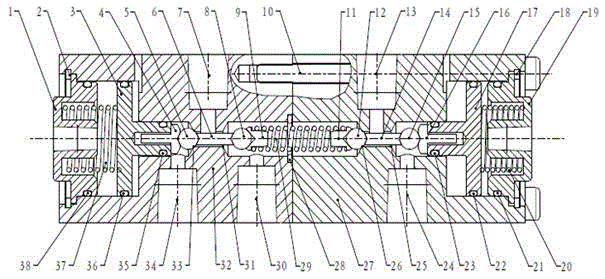

[0034] This embodiment discloses a pneumatic hydraulic three-position five-way reversing valve, which is characterized in that it includes a valve body, a pneumatic piston, a pneumatic piston plug, a ball seat, a stem, a steel ball and a central spring; the names of the components are as follows: Left pneumatic piston plug 1, left circlip 2, left pneumatic piston 3, No. 1 ball seat 4, No. 1 steel ball 5, left stem 6, left oil outlet 7, No. 2 steel ball 8 , No. 2 ball seat 9, bolt 10, No. 3 ball seat 11, No. 3 steel ball 12, right oil outlet 13, right stem 14, No. 4 steel ball 15, No. 4 ball seat 16, right pneumatic Piston 17, right circlip 18, right pneumatic piston plug, 19, right spring 20, right plug seal ring 21, right piston rear end seal ring 22, right piston front end seal ring 23, right Oil return port 24, No. 5 ball seat 25, No. 6 ball seat 26, right valve body 27, valve body connecting seal ring 28, central spring 29, oil inlet 30, No. 7 ball seat 31, left valve body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com