Rotary fixed lamp and mounting method thereof

An installation method and a technology for fixing a plate, which are applied in the directions of fixing lighting devices, light source fixing, lighting devices, etc., can solve the problems of high labor cost, many steps, inability to effectively prevent water leakage, etc., and achieve a simple fixing method and prevent reversal. , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

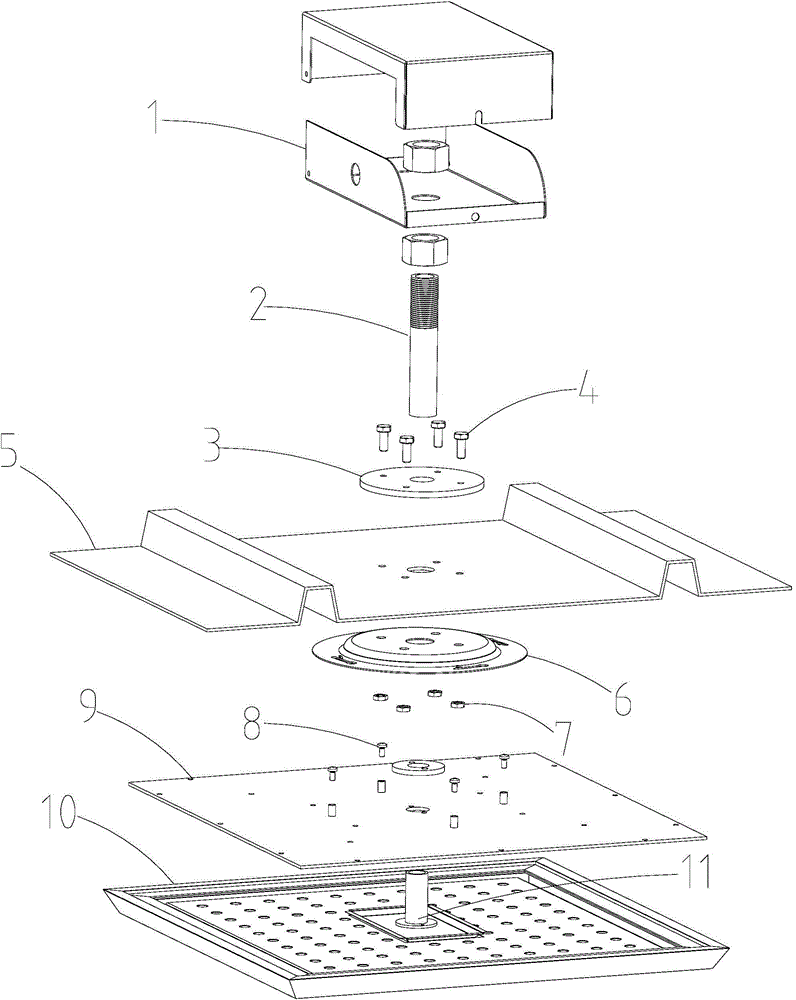

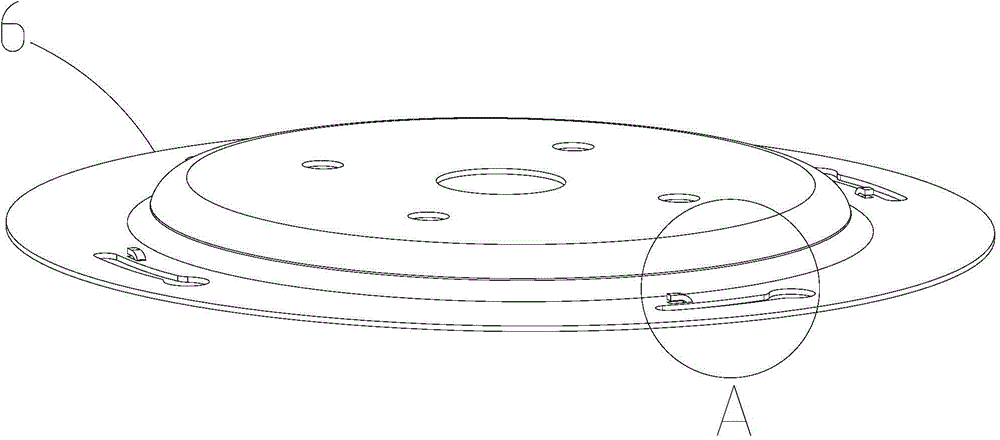

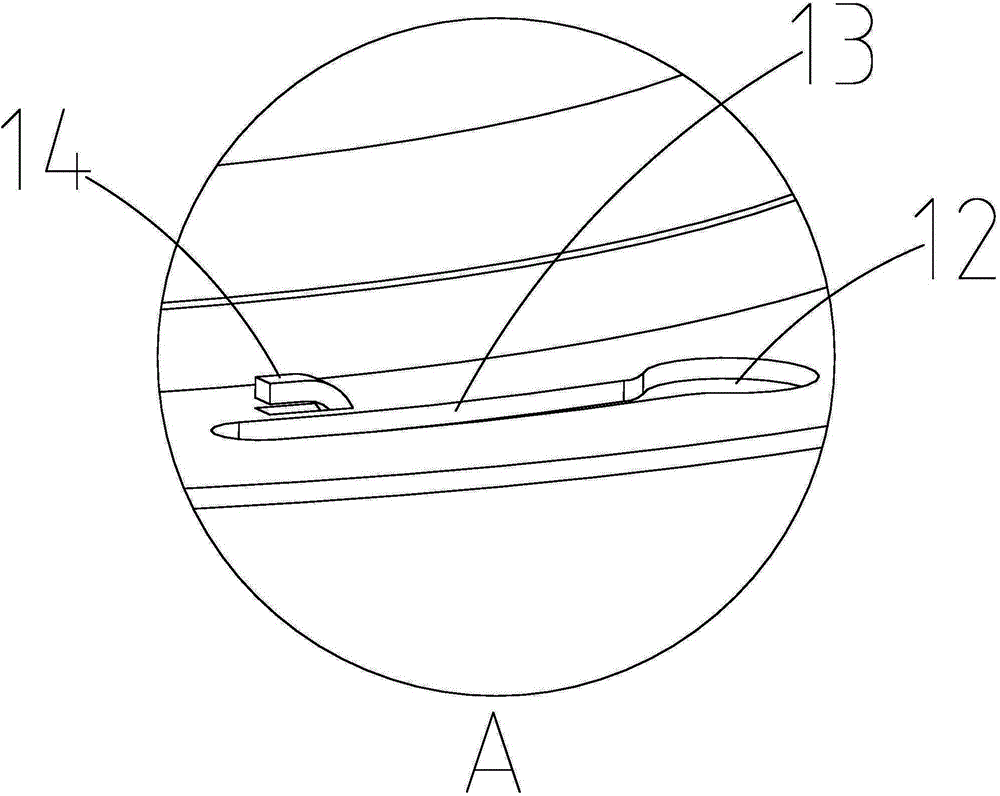

[0043] like figure 1 As shown, a rotating and fixed lamp includes a lamp body 10 and a top plate 5, and a fixing plate 6 is connected to the bottom of the top plate, such as figure 2 shown and combined with image 3 , the fixed plate is provided with an insertion hole 12 and a chute hole 13, the insertion hole communicates with the chute hole, the lamp body is provided with a pan head screw 8, and the aperture of the insertion hole is larger than or It is equal to the diameter of the head of the pan head screw, and the hole diameter of the chute hole is smaller than the head diameter of the pan head screw. After the pan head screw passes through the insertion hole and moves into the chute hole, the lamp body connected to the bottom of the top plate.

[0044] It includes at least two chute holes, the number of pan head screws corresponds to the number of chute holes, and all chute holes are symmetrically distributed around any point on the fixing plate, preferably centered s...

Embodiment 2

[0055] combine Figure 13 Shown, there are following advantages and disadvantages in embodiment 1:

[0056] advantage:

[0057] 1. Only one worker is needed to complete the work during the whole installation process. It greatly saves the cost of workers, especially in the United States, workers start charging when they leave home, until they arrive home after the installation is completed. This saves at least one worker the cost of going back and forth to the installation site and from the installation site to home.

[0058] 2. The installation process of the lamp body is convenient, quick and simple. Insert the lamp body into the corresponding hole and rotate to complete the installation of the lamp body.

[0059] shortcoming

[0060] 1. In the installation step, use nuts to fix and tighten the screws on the top of the color steel plate (top plate). Untightening occurs. The phenomenon of preventing the screw from rotating needs to be solved to ensure that the screw can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com