A heat recovery type sewage source heat pump system

A sewage source heat pump and heat recovery technology, applied in heat pumps, lighting and heating equipment, mechanical equipment, etc., can solve the problems of low utilization rate of heat energy of discharged sewage, and achieve the effect of high efficiency utilization and high energy efficiency ratio of units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

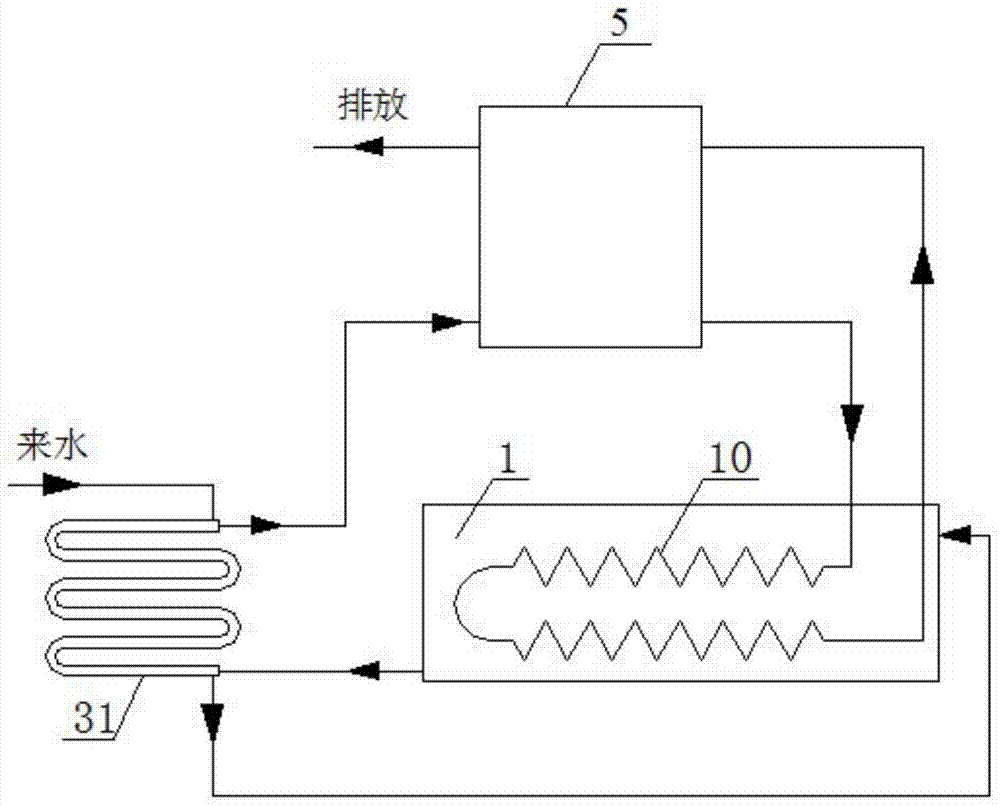

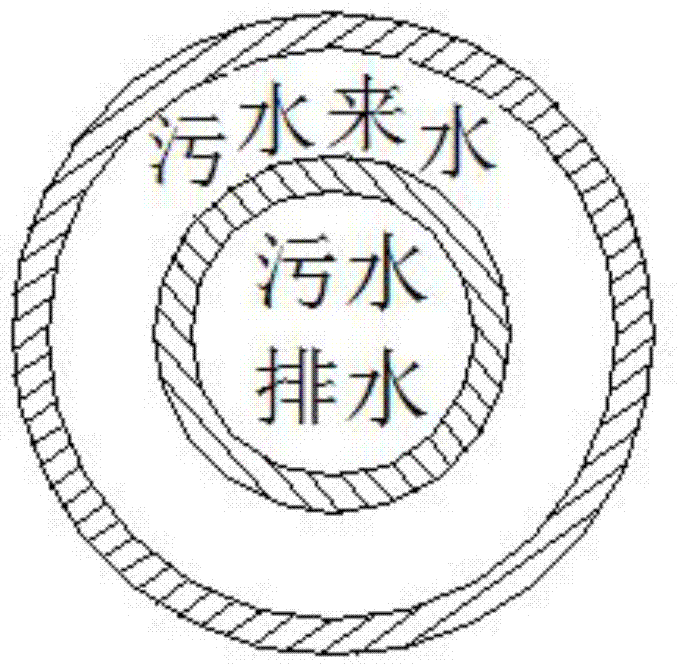

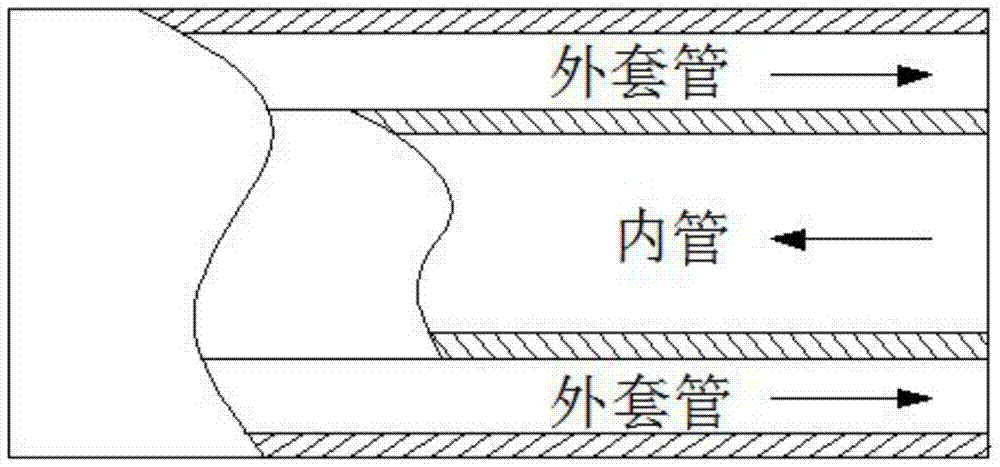

[0048] Such as Figure 4 Shown is a schematic structural diagram of Embodiment 1 of a heat recovery type sewage source heat pump system provided by the present invention, which is composed of Figure 4 It can be seen that, in the embodiment of the heat recovery type sewage source heat pump system provided by the present invention, the first sewage pump 21 is arranged between the water inlet of the inner pipe of the primary casing heat exchanger 31 and the sewage outlet of the biochemical pool 1; A second sewage pump 22 is arranged between the water outlet of the outer casing of the primary casing heat exchanger 31 and the water inlet of the biochemical pool 1 .

[0049] The heating coil 10 is a refrigerant heating coil. The heat pump unit 5 is replaced by an evaporator 6 , a throttle element 7 and a compressor 8 . The water outlet of the inner tube of the primary casing heat exchanger 31 is connected to the water source side water inlet of the evaporator 6, and the water sou...

Embodiment 2

[0052] Such as Figure 5 Shown is a schematic structural diagram of Embodiment 2 of a heat recovery type sewage source heat pump system provided by the present invention. Figure 5 It can be seen that, in the embodiment of the heat recovery type sewage source heat pump system provided by the present invention, the first sewage pump 21 is arranged between the water inlet of the inner pipe of the primary casing heat exchanger 31 and the sewage outlet of the biochemical pool 1; A second sewage pump 22 is arranged between the water outlet of the outer casing and the water inlet of the biochemical pool 1 .

[0053] The heating coil 10 is a hot water heating coil. The heat pump unit 5 includes an evaporator 6 , a throttle element 7 , a compressor 8 and a condenser 9 . The water outlet of the inner tube of the primary casing heat exchanger 31 is connected to the water source side water inlet of the evaporator 6, and the water source side water outlet of the evaporator 6 discharges ...

Embodiment 3

[0056] Such as Figure 6 Shown is a schematic structural diagram of Embodiment 3 of a heat recovery type sewage source heat pump system provided by the present invention. Figure 4 It can be seen that, in the embodiment of the heat recovery type sewage source heat pump system provided by the present invention, the first sewage pump 21 is arranged between the water inlet of the inner pipe of the primary casing heat exchanger 31 and the sewage outlet of the biochemical pool 1; A second sewage pump 22 is arranged between the water outlet of the outer casing and the water inlet of the biochemical pool 1 .

[0057] The heating coil 10 is a refrigerant heating coil. The heat pump unit 5 is replaced by an evaporator 6 , a throttle element 7 and a compressor 8 .

[0058] A secondary casing heat exchanger 32 is arranged between the primary casing heat exchanger 31 and the evaporator 6, and the water outlet of the inner tube of the primary casing heat exchanger 31 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com