A method for controlling the defrosting of an air-cooled refrigerator

The technology of an air-cooled refrigerator and a control method, which is applied to household refrigerators, defrosting, cooling machines, etc., can solve the problems of shortening the service life of refrigerators, increasing the energy consumption of defrosting air-cooling refrigerators, and poor cooling effects, so as to achieve saving Effects of refrigerator energy consumption, saving heating heat, and prolonging high-efficiency running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

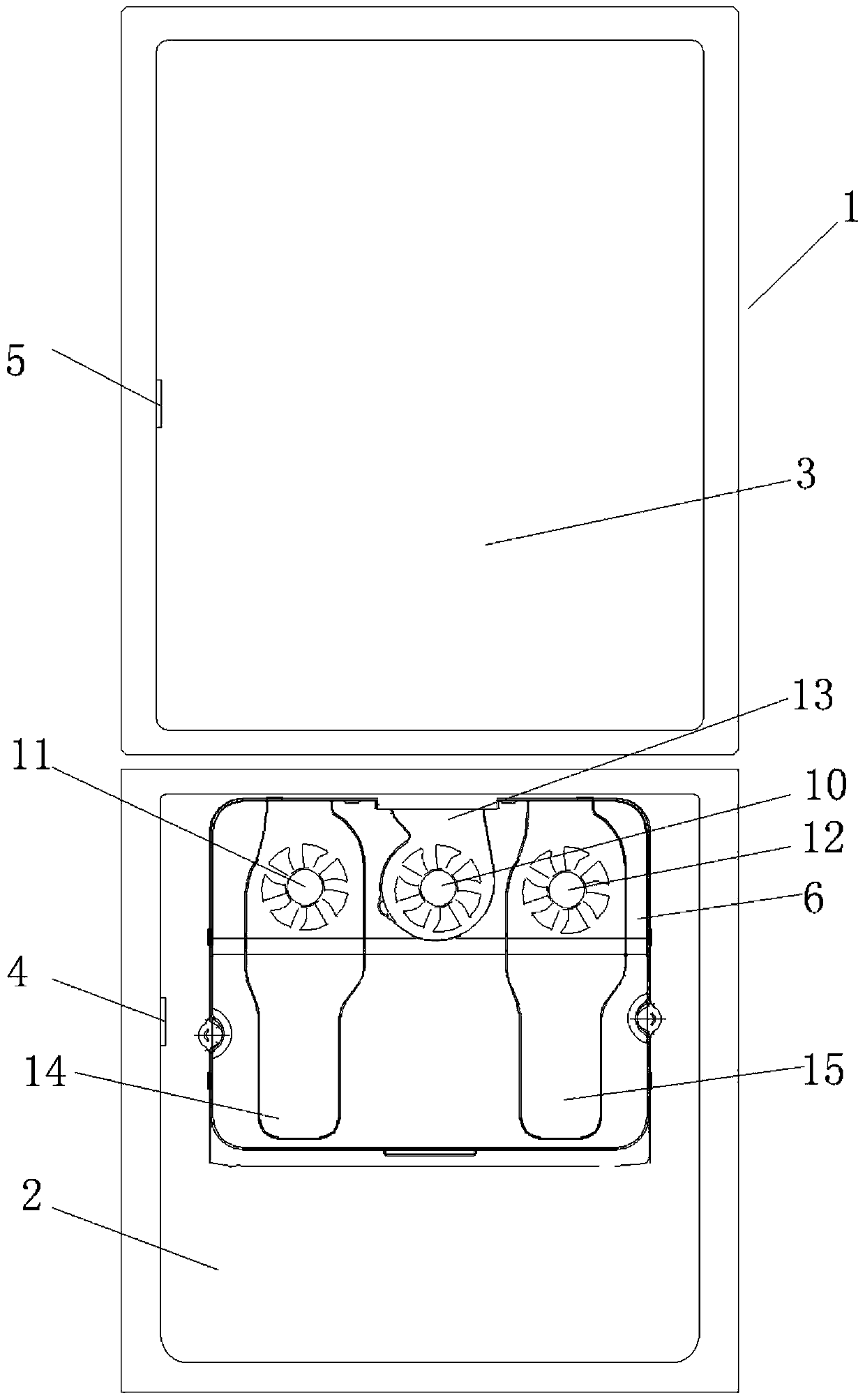

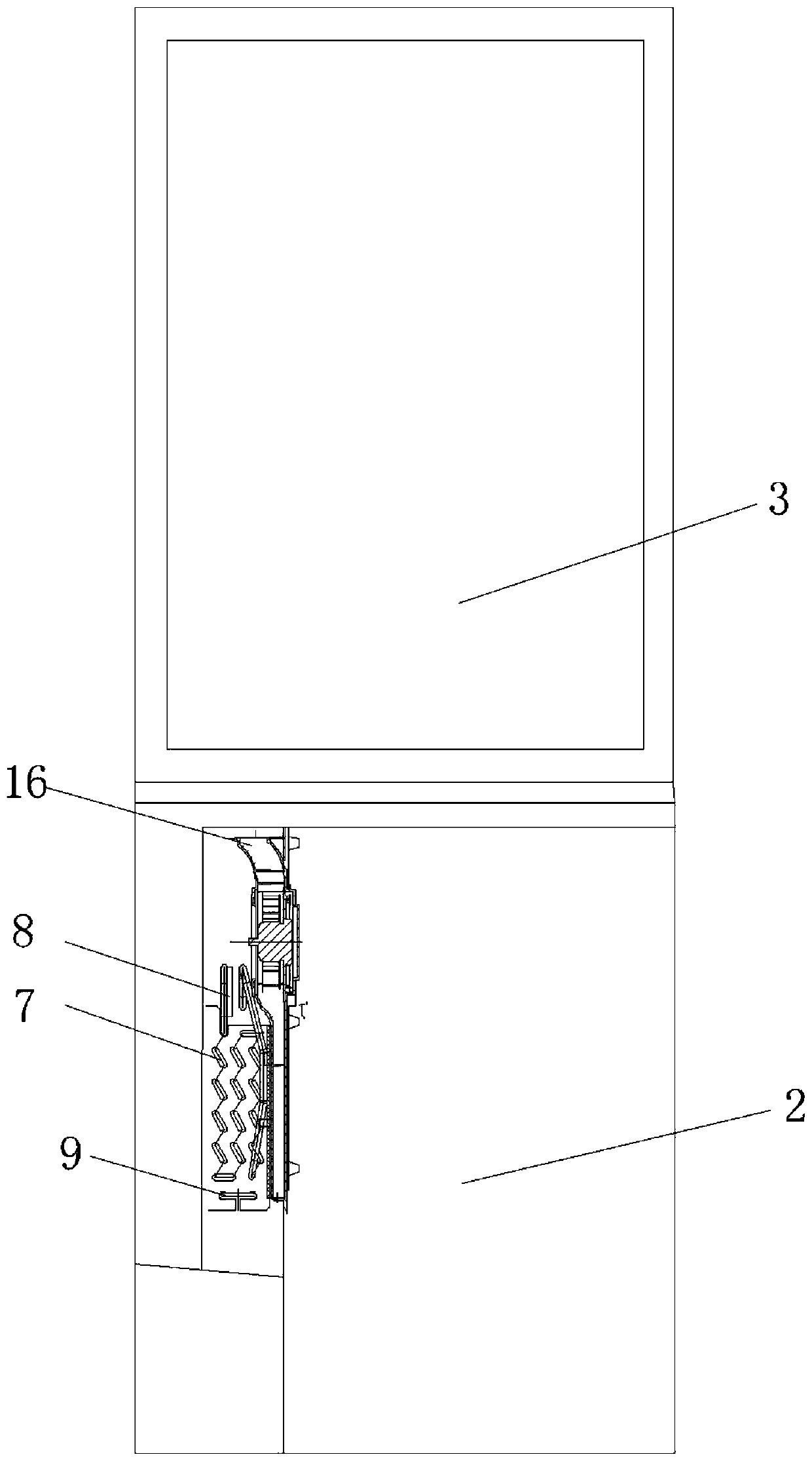

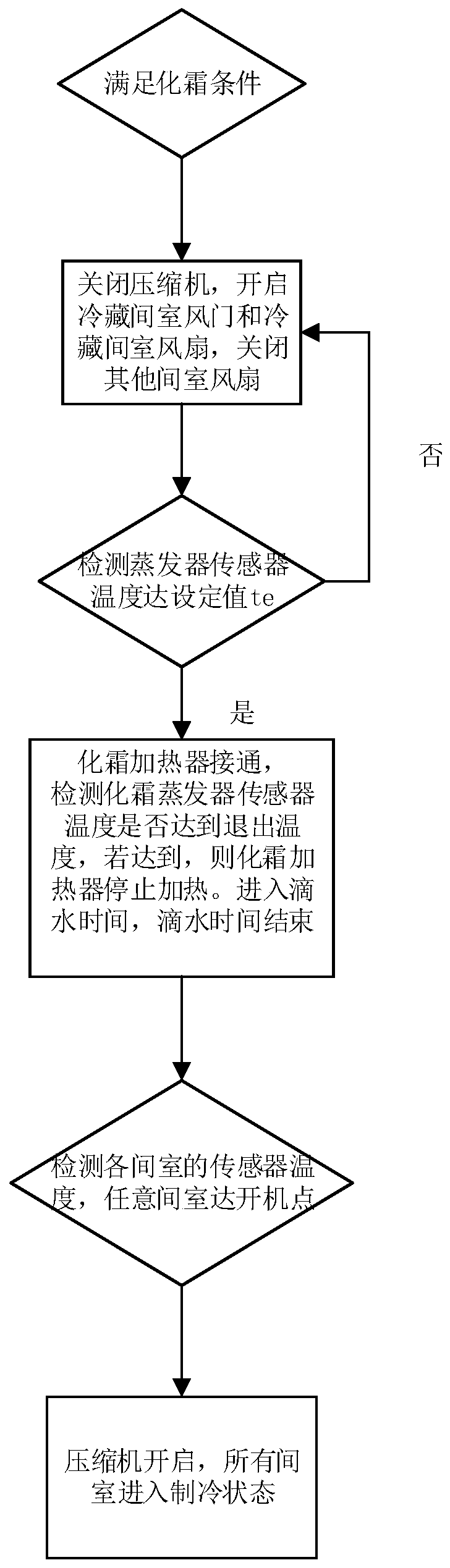

[0020] see figure 1 , figure 2 , the air-cooled refrigerator of the present embodiment comprises a casing 1, which has a freezer compartment 2 and a freezer compartment 3, and the freezer compartment 2 inner wall is provided with a sensor-4 for collecting the temperature of the freezer compartment 2, and the freezer compartment The inner wall of the chamber 3 is provided with a sensor 2 5 for collecting the temperature of the refrigerated compartment 3 . The evaporator chamber 6 is arranged on the back of the freezer chamber 2 in the box body 1, and the evaporator chamber 6 is provided with an evaporator 7 and an evaporator sensor for sensing the temperature of the evaporator 7 to control the on-off of the defrosting heater 9 8. Defrost heater 9, fan one 10, fan two 11, fan three 12 and air duct one 13, air duct two 14 and air duct three 15 corresponding to each fan one 10, air duct one 13 and the refrigerated room The room 3 is communicated with each other, the air duct 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com