Metering valve for additives at risk of freezing

A metering valve and valve body technology, applied in the field of metering valves, to achieve the effect of ensuring safe positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

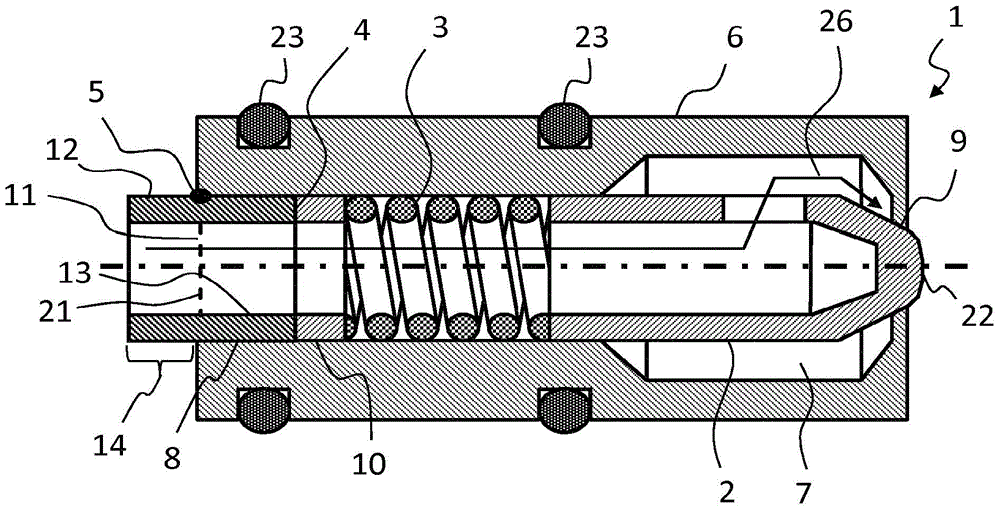

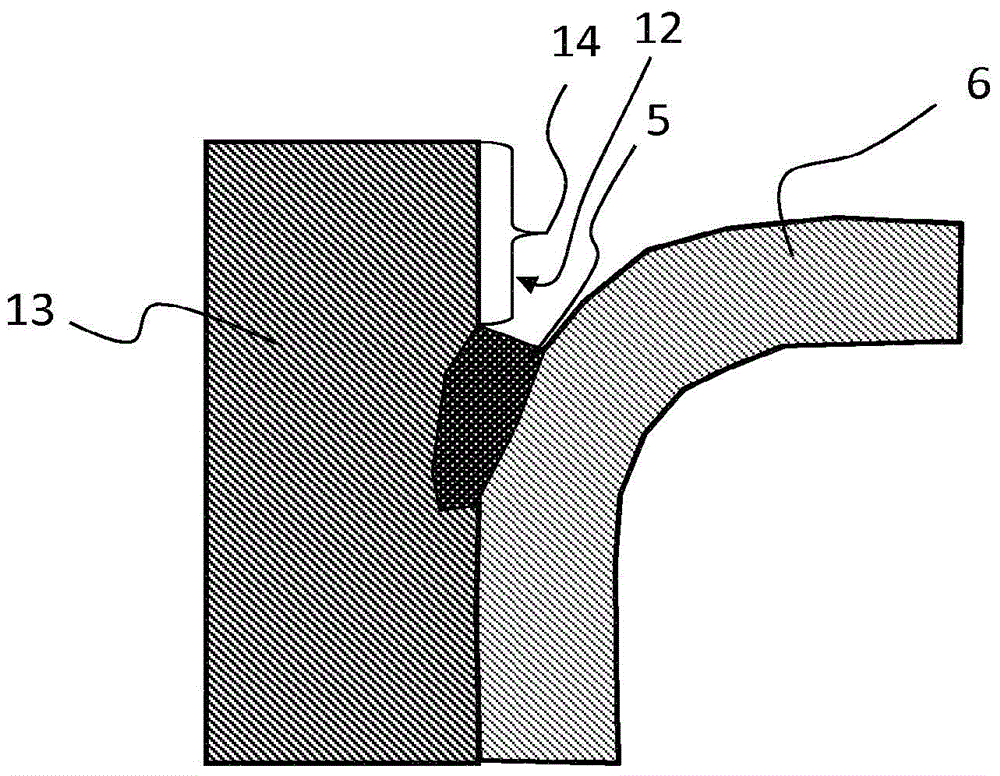

[0027] figure 1A metering valve 1 is shown with a valve housing 6 through which a channel 7 extends. The valve body 2 is arranged in the channel 7 . Valve body 2 is tensioned by spring 3 in metering valve 1 or in valve housing 6 or in channel 7 . To this end, the spring 3 is supported against the calibration body 4 . Calibration body 4 , spring 3 and valve body 2 are inserted into valve housing 6 via opening 11 of channel 7 . The calibrating body 4 is located in the channel section 8 of the channel 7 here. The spring 3 exerts a defined force on the valve body 2 which presses the valve body 2 against the closing seat 9 and thereby closes the metering valve 1 . The valve body 2 can be moved by a drive not shown against the spring force exerted by the spring 3, so that the valve body 2 moves away from the closing seat 9 and thereby opens the flow path 10 through the metering valve 1 from the inlet 21 to the outlet 22 and by This opens metering valve 1. The metering valve 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com